Preparation method of onium hydroxide

An oxide, onium hydrogen technology, applied in chemical instruments and methods, preparation of amino compounds from amines, organic chemistry, etc., can solve the problems of complex electrolysis equipment, by-product generation, etc., to reduce production costs, shorten the time of downtime, The effect of continuous operation for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

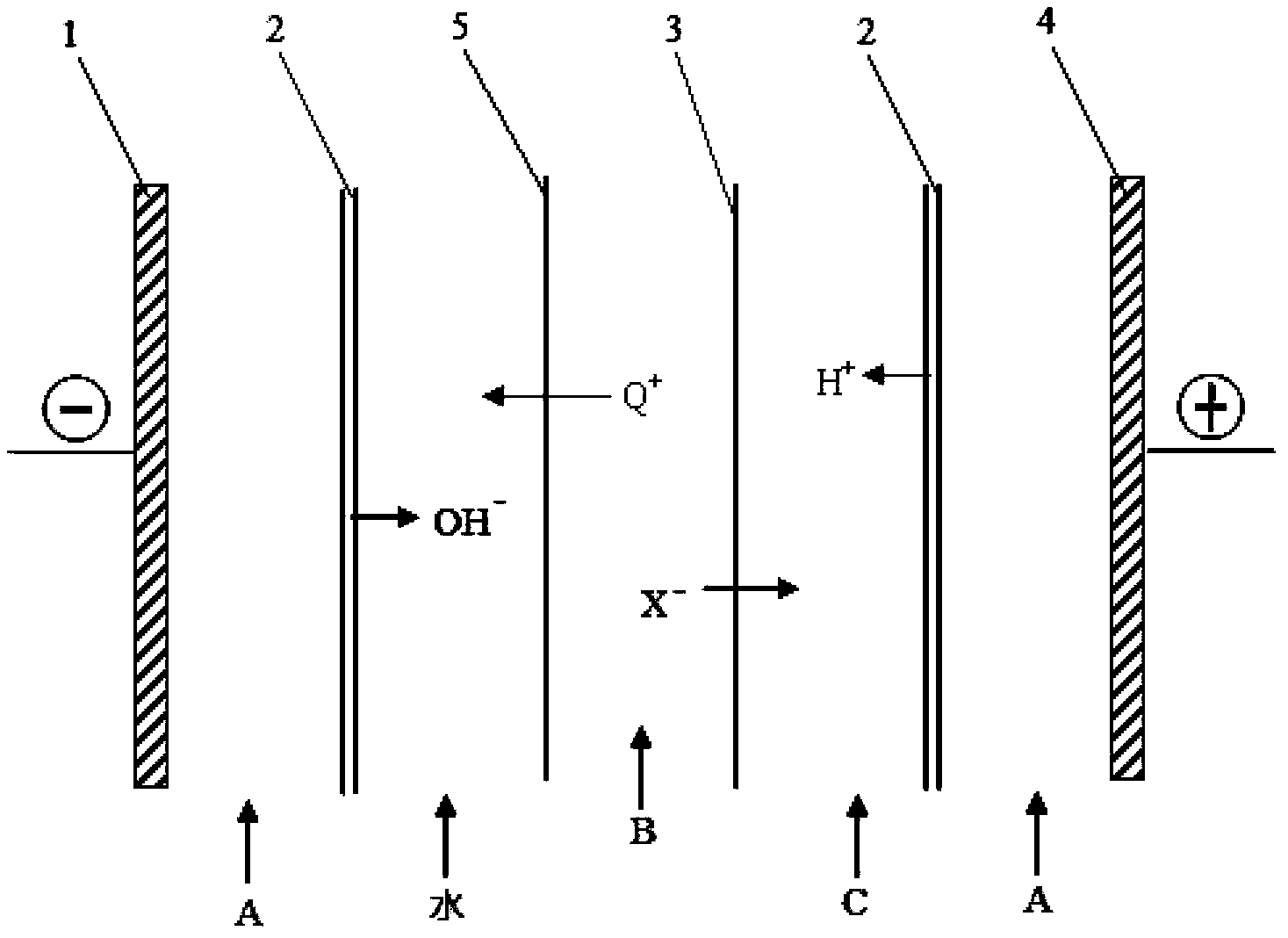

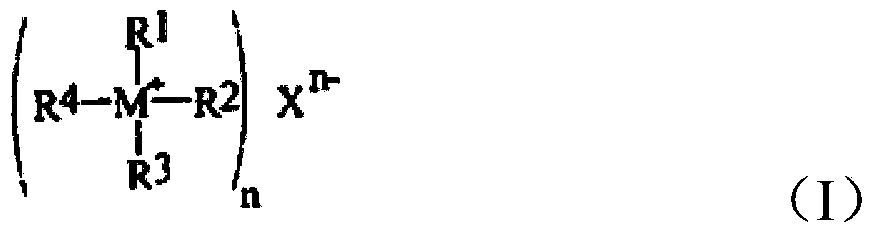

[0019] The invention provides a preparation method of onium hydroxide shown in formula I, the method comprising: sending the aqueous solution of onium salt shown in formula II into a bipolar membrane electrodialysis device, and performing bipolar membrane electrodialysis, Obtain the aqueous solution that contains the onium hydroxide shown in formula I, wherein, the method comprises sending neutralizing liquid into the acid chamber of bipolar membrane electrodialysis device, and described neutralizing liquid contains the acid-base reaction that can take place with HX substance,

[0020]

[0021] According to the method of the present invention, the onium salt represented by formula II can be properly selected according to the structure of the expected onium hydroxide, and can be various onium salts commonly used in the art. Generally, in formula I and formula II, M can be N, S or P; R 1 , R 2 , R 3 and R 4 same or different, each can be C 1 -C 20 Straight chain or bran...

Embodiment 1

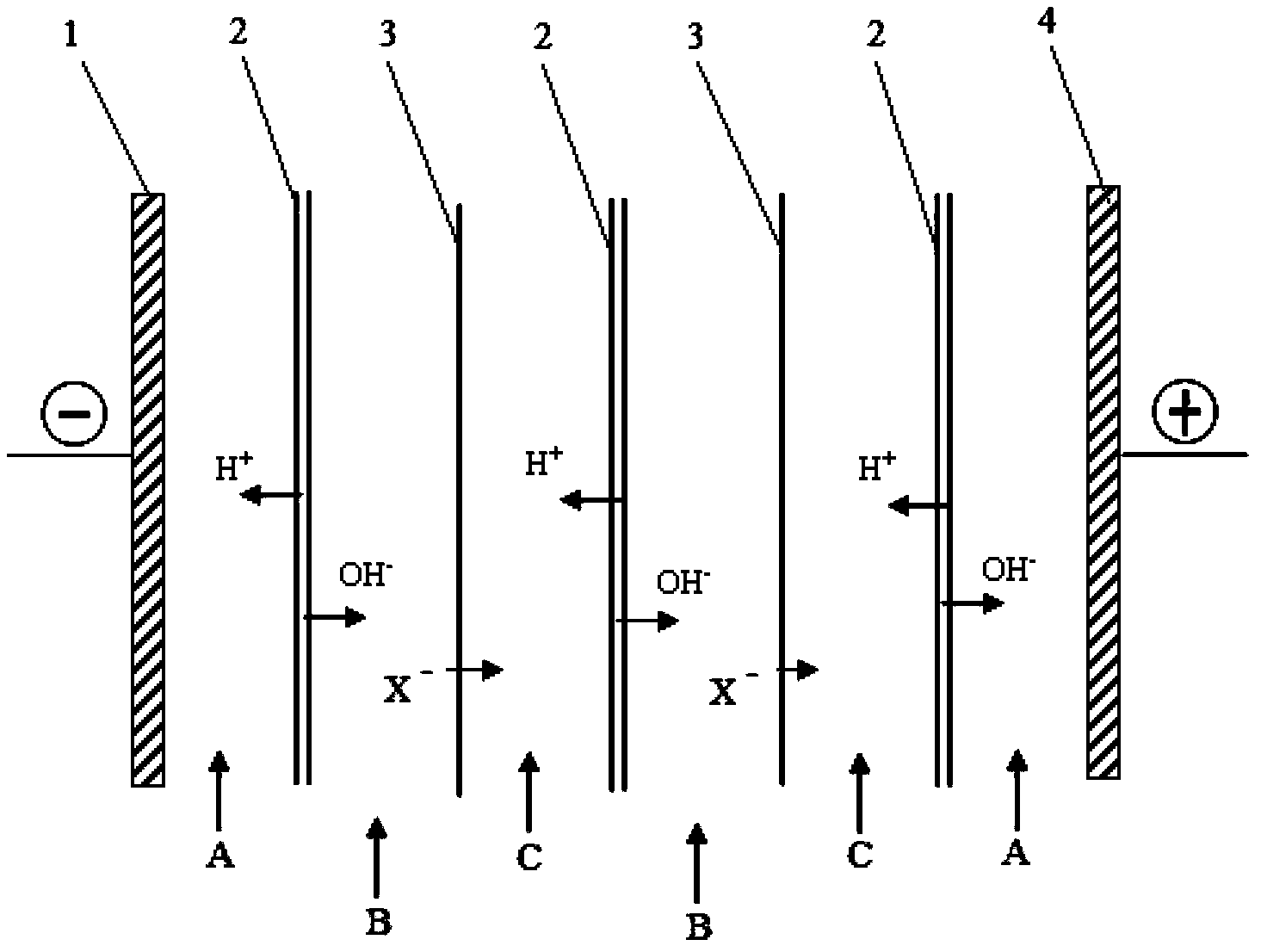

[0058] The membrane stack of the bipolar membrane electrodialysis device used in this embodiment is as figure 1 As shown, wherein, the number of bipolar membranes is 51, and the number of anion exchange membranes is 50.

[0059] Dissolve tetrapropylammonium bromide in water to prepare an aqueous solution with a concentration of 25% by weight, and place it in a feed liquid storage tank. NaOH was dissolved in water to prepare an aqueous solution with a concentration of 0.18% by weight as the polar liquid, and placed in the polar liquid storage tank. Ammonia water with a concentration of 2.5% by weight was used as a neutralizing solution, and the neutralizing solution was placed in a neutralizing solution storage tank.

[0060] Send the prepared tetrapropylammonium bromide aqueous solution into the alkali chamber of the bipolar membrane electrodialysis device, send the polar liquid into the anode chamber and cathode chamber of the bipolar membrane electrodialysis device, and sen...

Embodiment 2

[0069] Adopt the same method as Example 1 to prepare tetrapropyl ammonium hydroxide, the difference is that the neutralizing solution is a sodium hydroxide aqueous solution with a concentration of 0.8% by weight, and during continuous operation, the pH value of the neutralizing solution is controlled at 7 -8 range.

[0070] Production was carried out in the above-mentioned manner, and no abnormality was found in the continuous operation of the electrodialysis equipment for 2000 hours.

[0071] During the production process, the purity of each batch of aqueous solution containing tetrapropylammonium hydroxide was detected, and it was found that the purity of the aqueous solution obtained by each batch was stable, wherein the concentration of tetrapropylammonium hydroxide was 17.12% by weight , Na + The content is 350wppm, Br - The content is 0.38% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com