Preparation method of impact resistant polycarbonate

A polycarbonate, impact-resistant technology, applied in the field of polymer materials, can solve the problems of low fatigue strength, low melting point and glass transition temperature, stress cracking, etc., and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

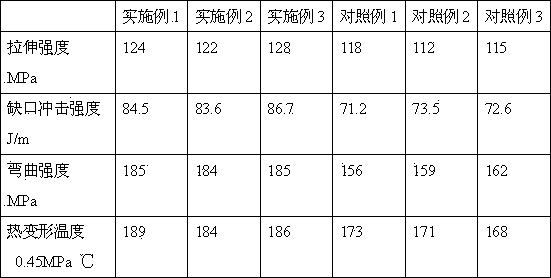

Examples

Embodiment 1

[0021] The preparation method of impact-resistant polycarbonate comprises the steps:

[0022] Step 1. Preparation of the prefabricated body: Take 20 Kg of fatty acid calcium, heat it to 150°C, then add 20 Kg of silicon oxide powder and 0.5 Kg of glass fiber, stir evenly, and after cooling, a modified powder is obtained; then the modified The powder and 10 Kg of polyethylene are initially mixed in a mixer, and then 5 Kg of ethylene bisstearamide and 5 Kg of chlorinated polyethylene are added. After heating up, mix evenly, and cool to room temperature to obtain a preform. The glass fiber The length is 10-500 microns;

[0023] Step 2, mix the prefabricated body, polycarbonate 40Kg, butanediol diacrylate 3Kg, antioxidant 0.5Kg, silane coupling agent KH-570 0.5Kg, and lubricant 0.5Kg evenly to obtain the mixture; The antioxidant is Antioxidant 1010;

[0024] The third step is to send the mixture into the twin-screw extruder for extrusion and granulation. The extrusion temperature...

Embodiment 2

[0027] The preparation method of impact-resistant polycarbonate comprises the steps:

[0028] Step 1. Preparation of prefabricated body: Take 30 Kg of fatty acid calcium, heat it to 170°C, then add 30 Kg of silicon oxide powder and 1 Kg of glass fiber, stir evenly, and after cooling, a modified powder is obtained; then the modified The powder and 20 Kg of polyethylene were initially mixed in a mixer, and then 10 Kg of ethylene bisstearamide and 10 Kg of chlorinated polyethylene were added. After heating up, they were mixed evenly and cooled to room temperature to obtain a preform. The glass fiber The length is 10-500 microns;

[0029] Step 2, mix the preform, polycarbonate 60Kg, butanediol diacrylate 5Kg, antioxidant 1Kg, silane coupling agent KH-570 1Kg, and lubricant 1Kg to obtain a mixture; The agent is antioxidant 1010;

[0030] The third step is to send the mixture into the twin-screw extruder for extrusion and granulation. The extrusion temperature of the twin-screw ex...

Embodiment 3

[0033] The preparation method of impact-resistant polycarbonate comprises the steps:

[0034] Step 1. Preparation of the prefabricated body: Take 25 Kg of fatty acid calcium, heat it to 160°C, then add 25 Kg of silicon oxide powder and 0.8 Kg of glass fiber, stir evenly, and obtain a modified powder after cooling; The powder and 15 Kg of polyethylene were initially mixed in a mixer, and then 8 Kg of ethylene bisstearamide and 7 Kg of chlorinated polyethylene were added. After heating up, they were mixed evenly and cooled to room temperature to obtain a preform. The glass fiber The length is 10-500 microns;

[0035] Step 2, mix the prefabricated body, polycarbonate 50Kg, butanediol diacrylate 4Kg, antioxidant 0.6Kg, silane coupling agent KH-570 0.8Kg, and lubricant 0.6Kg evenly to obtain the mixture; The antioxidant is Antioxidant 1010;

[0036] The third step is to send the mixture into the twin-screw extruder for extrusion and granulation. The extrusion temperature of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com