Preparation method of porous carbon ball-loaded M-Sn alloy nano particle composite material

A technology of alloy nanoparticles and composite materials, which is applied in the field of preparation of porous carbon ball-supported M-Sn alloy nanoparticle composite materials, can solve the problems of capacity decline, limited development and application, unstable cycle performance, etc., and achieves uniform heating and wide Development prospects and application space, the effect of stable product morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

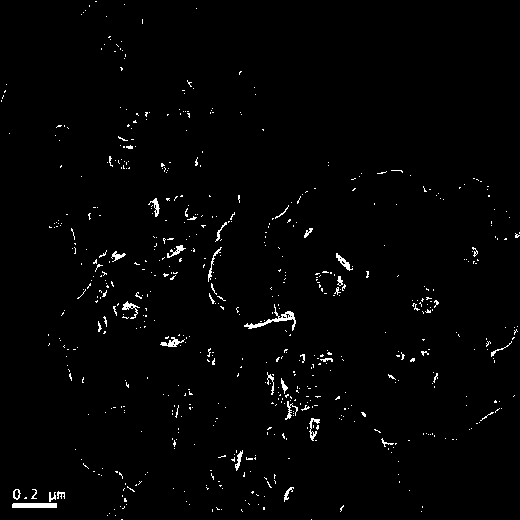

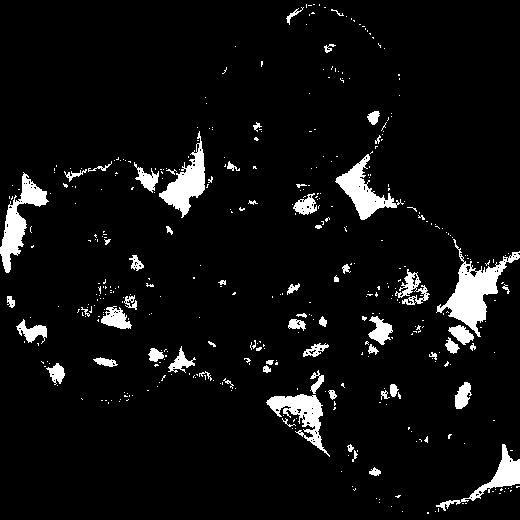

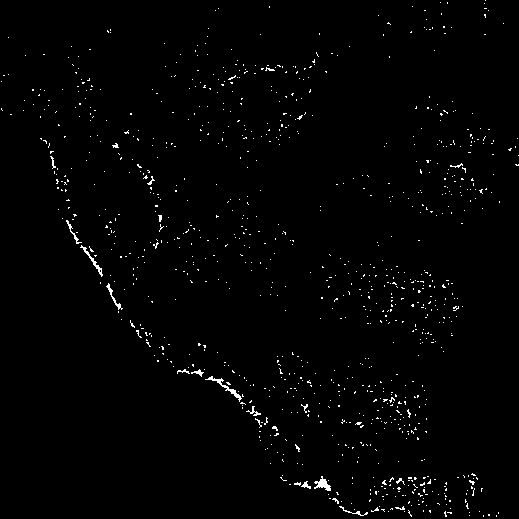

Image

Examples

Embodiment 1

[0042] 1) Preparation of porous carbon spheres by high temperature spray pyrolysis

[0043] In the first step, weigh 17.4g of sodium chloroacetate and dissolve it in 100mL of deionized water, add it to the humidifier to generate mist;

[0044] In the second step, 1.2L / min argon gas is continuously fed into the humidifier, and the mist is introduced into the quartz tube of the tube furnace working at 700°C;

[0045] The third step is to use absolute ethanol to collect the gas discharged from the quartz tube;

[0046] In the fourth step, the product was centrifuged at 5000 rpm to collect the precipitate, and dried in a vacuum oven at 60° C. for 5 hours, and the obtained product was porous carbon spheres.

[0047] 2) Synthesis of SnFe alloy nanoparticle composites supported by porous carbon spheres

[0048] In the first step, accurately weigh 0.025g of porous carbon spheres and disperse them in 50mL of triethylene glycol, then add 0.0564g of SnCl 2 2H 2 O After ultrasonic mix...

Embodiment 2

[0053] 1) Preparation of porous carbon spheres by high temperature spray pyrolysis

[0054]In the first step, weigh 11.6g of sodium chloroacetate and dissolve it in 100mL of deionized water, add it into a humidifier to generate mist;

[0055] The second step is to continuously feed 1.0L / min argon into the humidifier, and introduce the mist into the quartz tube of the tube furnace working at 700°C;

[0056] The third step is to use absolute ethanol to collect the gas discharged from the quartz tube;

[0057] In the fourth step, the product was centrifuged at 5000 rpm to collect the precipitate, and dried in a vacuum oven at 60°C for 10 hours, and the obtained product was porous carbon spheres.

[0058] 2) Synthesis of SnCo nanoparticle composites supported by porous carbon spheres

[0059] In the first step, accurately weigh 0.030g of porous carbon spheres and disperse them in 50mL of triethylene glycol, then add 0.0564g of SnCl 2 2H 2 O After ultrasonic mixing, transfer to...

Embodiment 3

[0064] 1) Preparation of porous carbon spheres by high temperature spray pyrolysis

[0065] In the first step, weigh 11.6g of sodium chloroacetate and dissolve it in 100mL of deionized water, add it into a humidifier to generate mist;

[0066] In the second step, 1.0L / min argon gas is continuously introduced into the humidifier, and the mist is introduced into the quartz tube of the tube furnace working at 650°C;

[0067] The third step is to use absolute ethanol to collect the gas discharged from the quartz tube;

[0068] In the fourth step, the product was centrifuged at 5000 rpm to collect the precipitate, and dried in a vacuum oven at 60° C. for 5 hours, and the obtained product was porous carbon spheres.

[0069] 2) Synthesis of porous carbon sphere-supported SnNi nanoparticle composites

[0070] In the first step, accurately weigh 0.025g of porous carbon spheres and disperse them in 50mL of triethylene glycol, then add 0.0564g of SnCl 2 2H 2 After ultrasonically mixi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com