High-frequency vacuum induction melting device and method for melting amorphous alloy using the same

A technology of vacuum induction and melting device, which is applied to the equipment for feeding molten metal into the mold, metal processing equipment, lighting and heating equipment, etc., which can solve the problems of multi-energy, energy consumption, unfavorable heat exchange, etc. Accurate composition, small footprint, fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

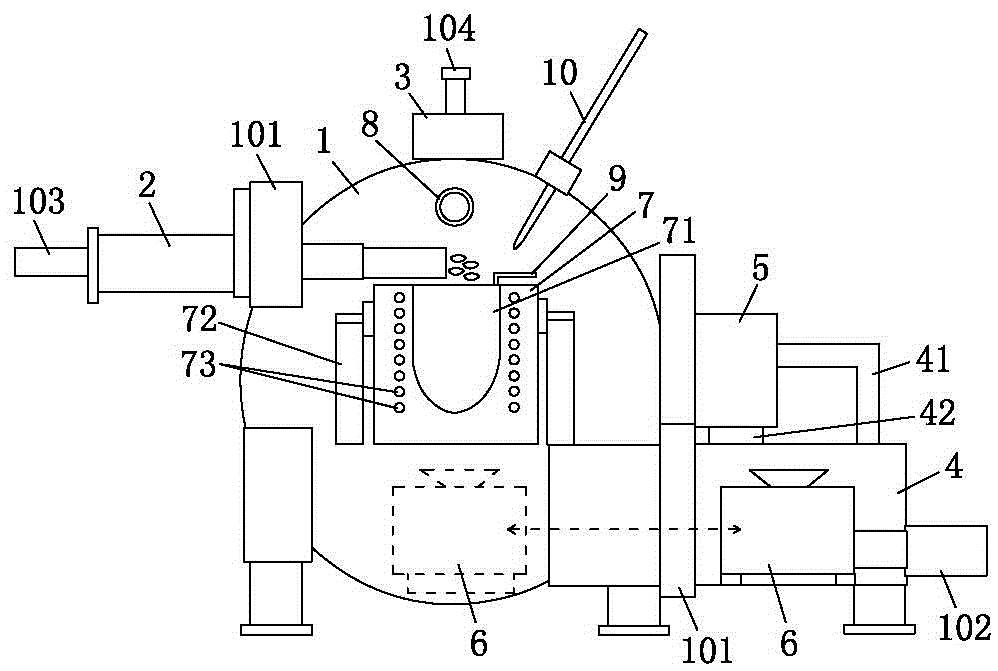

[0058] See figure 1 . The high-frequency vacuum induction melting device of the present embodiment comprises five independent chambers of a melting chamber 1, a material supply chamber 2, an additional charging chamber 3, a mold chamber 4 and a cooling chamber 5; The mold device 6; the material supply chamber 2, the additional charging chamber 3 and the mold chamber 4 are respectively connected to the melting chamber 1, and are all isolated by a valve 101; an air outlet pipe 41 and an air inlet pipe 42 are connected between the mold chamber 4 and the cooling chamber 5 ; In the mold cooling process, the hot gas in the mold chamber 4 is imported into the cooling chamber 5 through the air outlet pipe 41 for cooling, and the cooled gas is transported back into the mold chamber 4 through the air inlet pipe 42, thereby realizing the cooling of the mould.

[0059] Wherein, the cooling chamber 5 is provided with a heat exchanger; since the heat exchanger is arranged in the cooling ch...

Embodiment 2

[0071] A method for melting amorphous alloys of the present embodiment, the method for melting amorphous alloys is to utilize the high-frequency vacuum induction melting device of embodiment 1 (see figure 1 ) method for melting amorphous alloy, it comprises the following steps:

[0072] Step 1, the melting chamber 1 is evacuated and filled with an inert atmosphere: the melting chamber 1 is evacuated to 10 -4 The vacuum degree of torr pours into the inert atmosphere that accounts for 20% of the total volume of the melting chamber 1 then to the melting chamber 1; Wherein, the inert atmosphere of the present embodiment is argon;

[0073] Step 2, after balancing the pressures of the melting chamber 1 and the material supply chamber 2, input raw materials from the material supply chamber 2 to the crucible furnace device 7 of the melting chamber 1;

[0074] Step three, the melting of raw materials, specifically includes the following steps:

[0075] A. Melting during charging: dur...

Embodiment 3

[0084] A method for melting amorphous alloys of the present embodiment, the method for melting amorphous alloys is to utilize the high-frequency vacuum induction melting device of embodiment 1 (see figure 1 ) method for melting amorphous alloy, it comprises the following steps:

[0085] Step 1, the melting chamber 1 is evacuated and filled with an inert atmosphere: the melting chamber 1 is evacuated to 10 -8 The vacuum degree of torr pours into the inert atmosphere that accounts for 30% of the total volume of the melting chamber 1 to melting chamber 1 then; Wherein, the inert atmosphere of the present embodiment is nitrogen;

[0086] Step 2, after balancing the pressures of the melting chamber 1 and the material supply chamber 2, input raw materials from the material supply chamber 2 to the crucible furnace device 7 of the melting chamber 1;

[0087] Step three, the melting of raw materials, specifically includes the following steps:

[0088] A. Fusion during charging: durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com