Method for preparing Ag/ZnO core-shell nanostructure by adopting pulse laser liquid ablation

A technology of nanostructure and liquid phase sintering, which is applied in the direction of nanotechnology, can solve the problems of restricting the application of chemical methods, and achieve the effect of simple and easy process operation and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

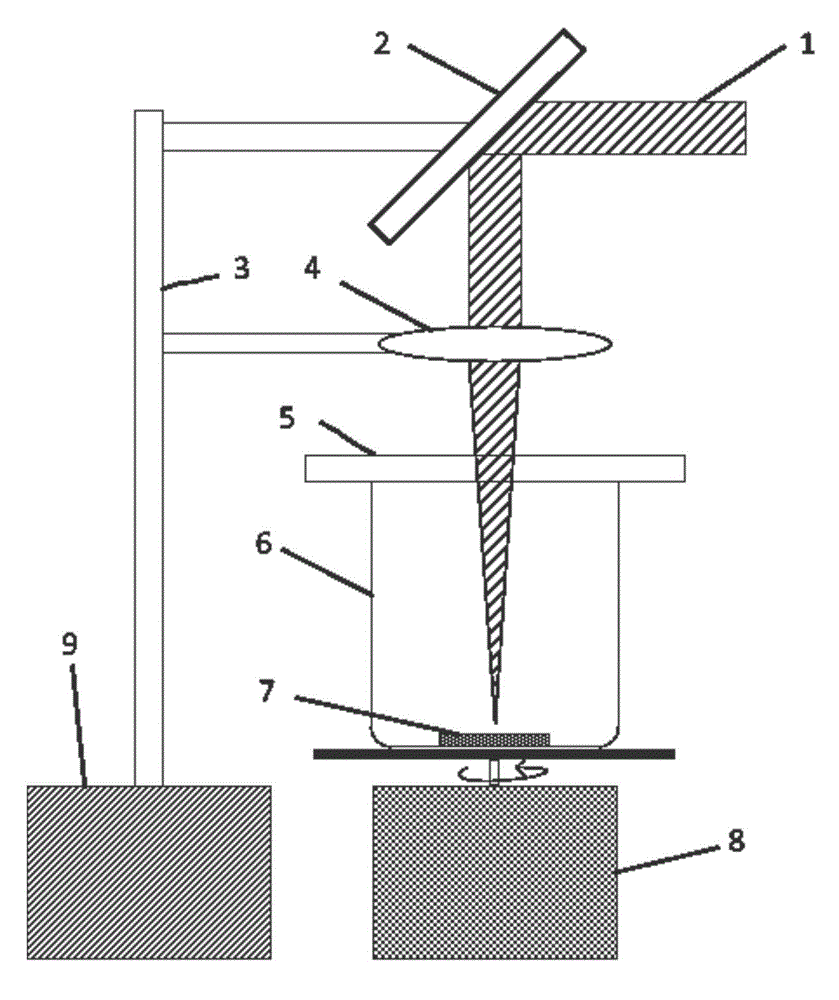

[0029] Soak the Ag target and Zn target in nitric acid for 1 minute to remove the surface oxide layer, mechanically polish the Ag and Zn targets with fine sandpaper, and ultrasonically clean the polished Ag and Zn metal targets in absolute ethanol and deionized water with an ultrasonic cleaner. . The ablation device used in the experiment was figure 1 shown. Place the cleaned Ag target on the bottom of a beaker filled with 10ml of deionized water, and place the beaker on a rotating platform at a rotation speed of 10 rpm. A KrF excimer laser with a wavelength of 248 nm (single pulse energy 400 mJ, repetition rate 10 Hz) was reflected and then focused on the surface of the Ag target to ablate the Ag target for 30 minutes. Take out the Ag target, place the Zn target in the prepared Ag colloid, and place the beaker on the rotating platform at a rotation speed of 10 rpm. The same laser parameters (wavelength 248nm, single pulse energy 400mJ, repetition frequency 10Hz) were used ...

Embodiment 2

[0035] Soak the Ag target and Zn target in nitric acid for 1 minute to remove the surface oxide layer, mechanically polish the Ag and Zn targets with fine sandpaper, and ultrasonically clean the polished Ag and Zn metal targets in absolute ethanol and deionized water with an ultrasonic cleaner. . The ablation device used in the experiment was figure 1 shown. Place the cleaned Ag target on the bottom of a beaker filled with 10ml of deionized water, and place the beaker on a rotating platform at a rotation speed of 15 rpm. A KrF excimer laser with a wavelength of 248 nm (single pulse energy 400 mJ, repetition rate 10 Hz) was reflected and then focused on the surface of the Ag target to ablate the Ag target for 20 minutes. Take out the Ag target, place the Zn target in the prepared Ag colloid, and place the beaker on the rotating platform at a rotation speed of 15 rpm. The same laser parameters (wavelength 248nm, single pulse energy 400mJ, repetition frequency 10Hz) were used ...

Embodiment 3

[0038] Soak the Ag target and Zn target in nitric acid for 1 minute to remove the surface oxide layer, mechanically polish the Ag and Zn targets with fine sandpaper, and ultrasonically clean the polished Ag and Zn metal targets in absolute ethanol and deionized water with an ultrasonic cleaner. . The ablation device used in the experiment was figure 1 shown. Place the cleaned Ag target on the bottom of a beaker filled with 10ml of deionized water, and place the beaker on a rotating platform at a rotation speed of 30 rpm. A KrF excimer laser with a wavelength of 248 nm (single pulse energy 400 mJ, repetition rate 10 Hz) was reflected and then focused on the surface of the Ag target to ablate the Ag target for 20 minutes. Take out the Ag target, place the Zn target in the prepared Ag colloid, and place the beaker on the rotating platform at a rotation speed of 30 rpm. Using the same laser parameters (wavelength 248nm, single pulse energy 400mJ, repetition rate 10Hz) to perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com