Amorphous alloy micro-nano structure stamping forming mould and preparation and application methods thereof

An amorphous alloy and micro-nano structure technology, applied in the field of material science and engineering, can solve the problems of complex photolithography technology, poor mold surface quality, large structure size, etc., and achieve good controllability, high molding efficiency, and small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

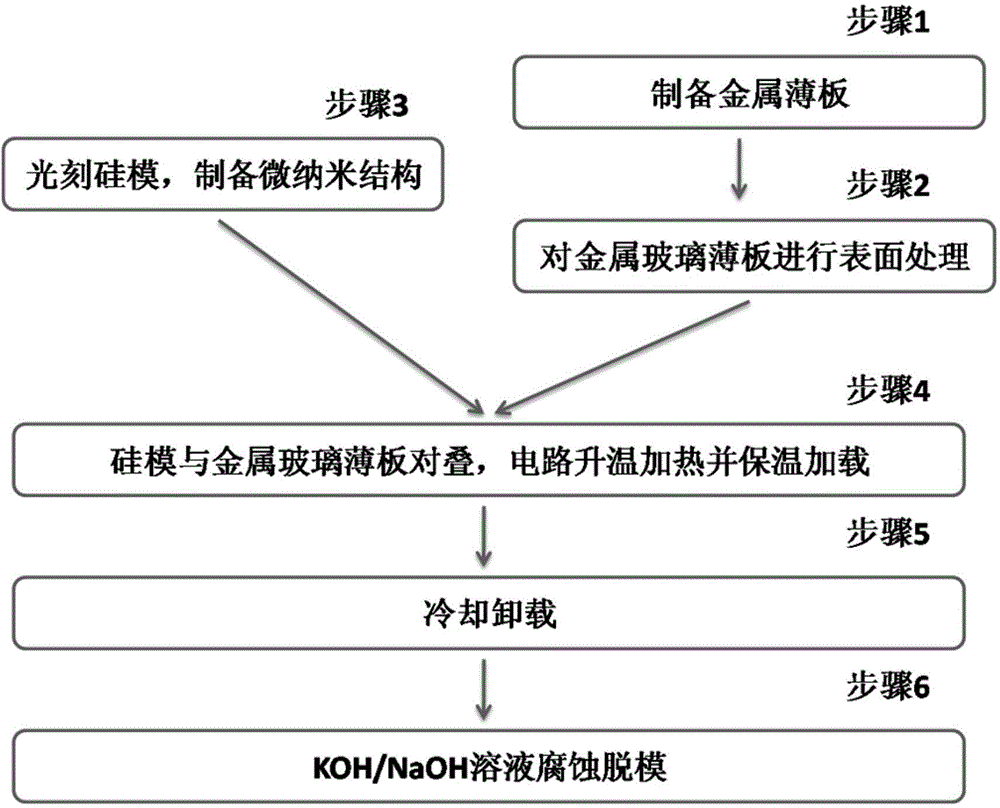

[0079] Preparation of imprint molding mold based on Ni-based amorphous alloy micro-nano structure:

[0080] The nominal composition was changed to Ni by traditional coating agent water quenching method 62 PD 19 Si 2 P 17 (atomic percent) of the alloy melt was cooled to obtain an amorphous alloy column with a diameter of 8 mm and a length of 3 cm.

[0081] The above-mentioned amorphous alloy cylinder was cut into thin slices with a thickness of 2mm by a cutting machine, and one side was polished to a smooth surface with No. 2000 sandpaper, and then polished on a polishing machine with a diamond polishing paste with a particle size of 1.5 μm.

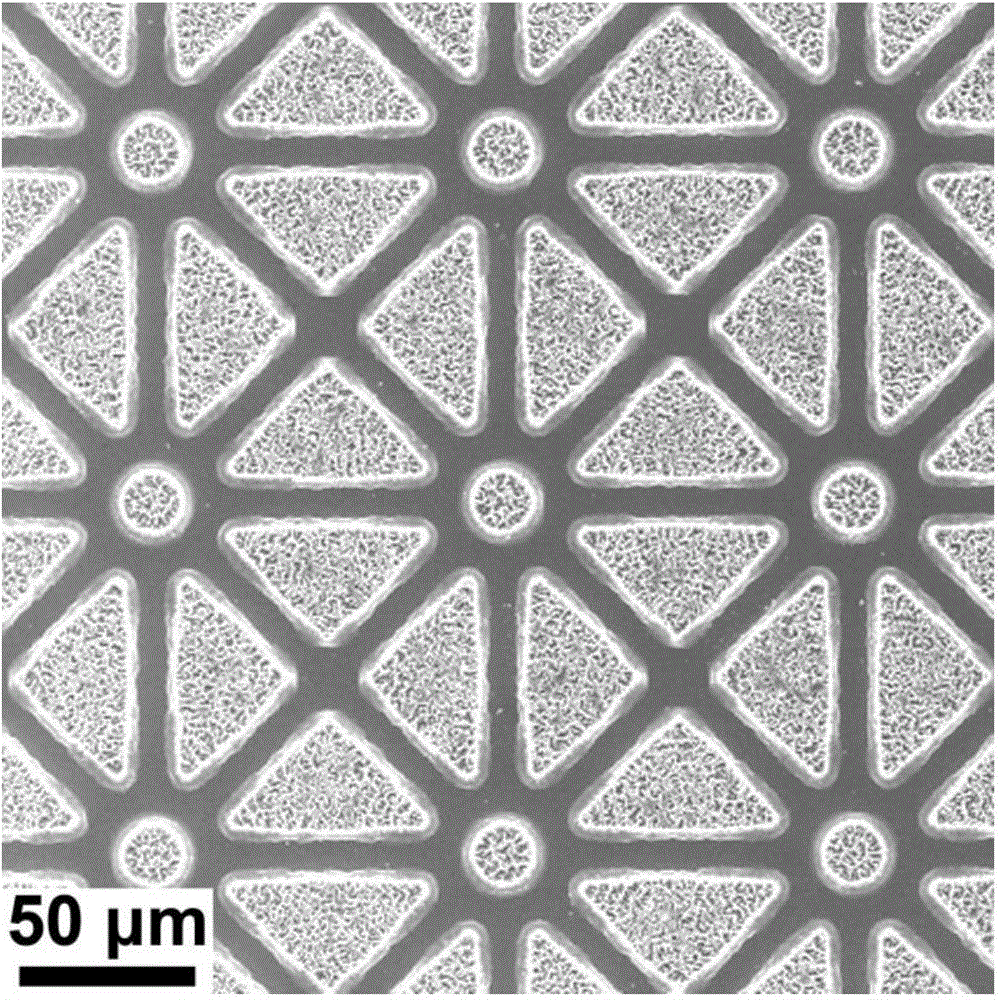

[0082] On the surface of the template with a size of 10 mm × 10 mm and a thickness of 0.5 mm, a complex periodic structure with a depth of 5 μm and a period of 100 μm was etched by photolithography technology to be used as a mold for thermal embossing of amorphous alloys. The periodic unit of the template is composed of cylinders and ...

Embodiment 2

[0085] Use Ni 62 PD 19 Si 2 P 17 Amorphous alloy micro-nano structure imprint molding mold imprints organic glass PMMA:

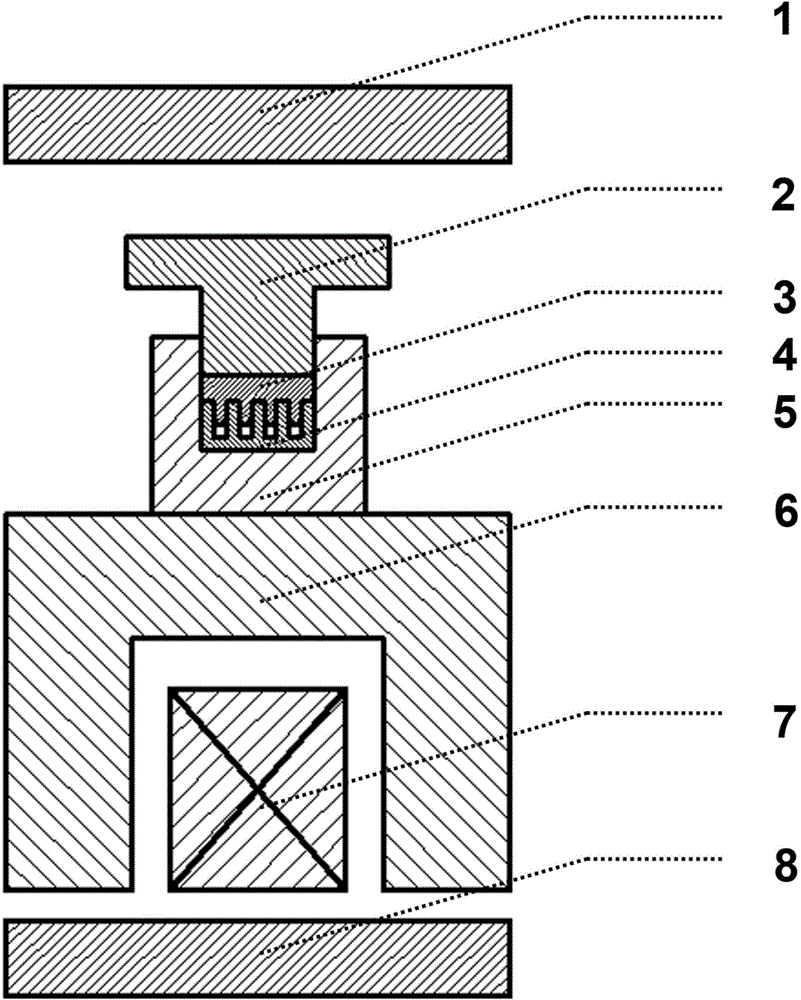

[0086] The plexiglass PMMA sheet is placed on the lower pressure head 8 of the compressor of the universal material testing machine, and then the amorphous alloy metal micro-nano imprint molding mold prepared in Example 1 is fixed on the attachment connected to the upper pressure head 1 of the compressor, The side with the micro-nano structure faces downward. An electric furnace is used to heat the imprint molding mold of the amorphous alloy micro-nano structure to 50 degrees above the PMMA amorphous transition temperature. Remove the electric furnace, apply pressure by moving the upper pressure head 1 of the compressor and the lower pressure head 8 of the compressor up and down, the compression rate is 2mm / min, when the pressure increases to 2MPa, keep the pressure for 3min, and then unload . Take off the plexiglass PMMA sheet and the amorphous alloy...

Embodiment 3

[0088] Based on Ni 62 PD 19 Si 2 P 17 The micro-nano structure imprinting molding on the surface of the 304 stainless steel plate of the amorphous alloy micro-nano structure imprinting mold:

[0089] Place the electropolished 304 stainless steel plate on the lower pressure head 8 of the compressor of the universal testing machine, with the polished side facing up. Then the Ni prepared by Example 1 62 PD 19 Si 2 P 17 The imprint molding mold of the amorphous alloy micro-nano structure is placed on the 304 stainless steel plate, and the side with the micro-nano structure faces down and faces the stainless steel plate. Apply pressure by moving up and down the upper head 1 of the compressor and the lower head 8 of the compressor of the universal testing machine. The compression rate is 0.2 mm / min. When the pressure increases to 100 MPa, keep the pressure for 3 minutes and then unload. Take off the 304 stainless steel plate and the imprinting mold of the amorphous alloy mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Feature size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com