Concrete repairing agent for bridge pavement and preparation method of concrete repairing agent

A concrete repair agent and bridge technology, applied in the field of building construction, can solve the problems of high brittleness and low elongation, achieve high strength and toughness, excellent erosion resistance, and not easy to corrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

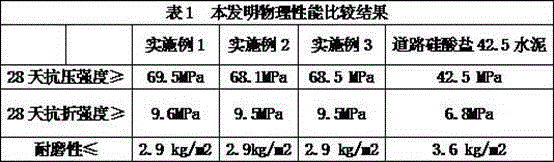

Embodiment 1

[0014] Embodiment 1: a, 10 kilograms of boronite, 7 kilograms of forsterite, 11 kilograms of lapis lazuli, and 3 kilograms of zinc hydroxide are made into 200-mesh powder, and they are mixed uniformly to obtain active powder A; b. 2 kg of triazole, 6 kg of hydroxypropyl methylcellulose, 4 kg of cyclomethicone, and 5 kg of triisopropanolamine; add to a mixer and stir for 20 minutes at a speed of 800-1000 rpm , to get composite additive B; c, add 42 kg of water to (Aoshun cement 42.5) ordinary portland cement 75 kg; then add active powder A and stir evenly, finally add composite additive B and Jiayuan building materials JW-VII polycarboxylic acid It is 1.5 kg of high-performance water reducer, stir well and serve. The concrete repair agent for bridge pavement, 28-day high compressive strength (GB 177 cement mortar strength test method) is 69.5MPa, 28-day flexural strength ≥ 9.6MPa, wear resistance (JC / T 421 cement mortar Abrasion resistance test method) expressed as wear amount...

Embodiment 2

[0015] Embodiment 2: a, 9 kilograms of boronite, 6 kilograms of forsterite, 10 kilograms of lapis lazuli, and 3 kilograms of zinc hydroxide are made into 200-mesh powder, and they are mixed uniformly to obtain active powder A; b, methylbenzo 2 kg of triazole, 65 kg of hydroxypropyl methylcellulose, 4 kg of cyclomethicone, and 4 kg of triisopropanolamine; add to a mixer and stir for 20 minutes at a speed of 800-1000 rpm , to obtain composite additive B; c. Add 38 kg of water to 70 kg of ordinary Portland cement (Aoshun cement 42.5); then add active powder A and stir evenly, and finally add composite additive B and Jiayuan building materials JW-VII polycarboxylic acid It is 1 kg of high-performance water reducer, stir well and serve. The concrete repair agent for bridge pavement, 28-day high compressive strength (GB 177 cement mortar strength test method) is ≥68.1MPa, 28-day flexural strength ≥9.5MPa, wear resistance (JC / T 421 cement glue Sand wear resistance test method) expre...

Embodiment 3

[0016] Embodiment 3: a, 12 kilograms of boronite, 8 kilograms of forsterite, 13 kilograms of lapis lazuli, and 4 kilograms of zinc hydroxide are made into 200 mesh powders, and they are mixed uniformly to obtain active powder A; b, methylbenzo 3 kg of triazole, 7 kg of hydroxypropyl methylcellulose, 5 kg of cyclomethicone, and 5 kg of triisopropanolamine; add to a mixer and stir for 20 minutes at a speed of 800-1000 rpm , to obtain composite additive B; c. Add 48 kg of water to 70 kg of ordinary Portland cement (Aoshun cement 42.5); then add active powder A and stir evenly, and finally add composite additive B and Jiayuan building materials JW-VII polycarboxylic acid It is 2 kg of high-performance water reducer, stir well and serve. The concrete repair agent for bridge pavement, 28-day high compressive strength (GB 177 cement mortar strength test method) is ≥68.5MPa, 28-day flexural strength ≥9.5MPa, wear resistance (JC / T 421 cement glue Sand wear resistance test method) expr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com