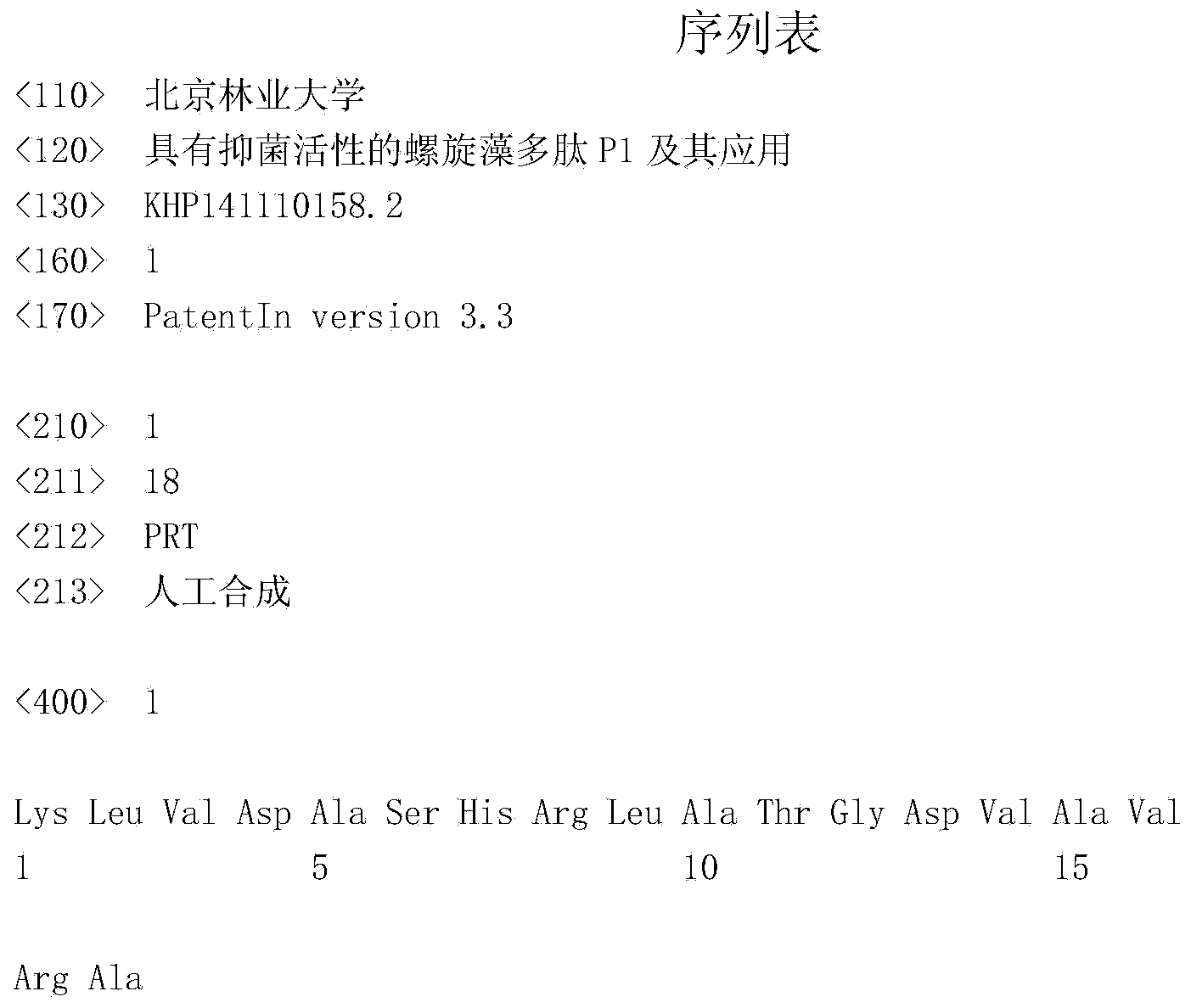

Spirulina polypeptide P1 with bacteriostatic activity, and application thereof

A technology of spirulina polypeptide and antibacterial activity, applied in the field of protein engineering, can solve problems such as unfavorable processing, unfavorable digestion and absorption, high viscosity, etc., and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The extraction of embodiment 1 spirulina protein

[0018] (1) Dissolve an appropriate amount of Spirulina platensis dry powder in distilled water to make a Spirulina suspension, and use ultrasound combined with repeated freezing and thawing to break the wall.

[0019] (2) Centrifuge the spirulina liquid obtained in step (1) (-4°C, 8000r / min for 20min) to collect the supernatant, and use 50% saturated NH4SO4 for salting-out purification.

[0020] (3) Refrigerate and centrifuge the spirulina liquid obtained after salting out in step (2) (10000r / min for 20min), collect the precipitate, dissolve it in a phosphate buffer solution with a concentration of 0.005M and a pH of 6.86, and dialyze at 4°C , The end point of dialysis was detected with BaCl2. After desalination, vacuum freeze-drying is carried out to obtain the spirulina protein.

Embodiment 2

[0021] The extraction of embodiment 2 spirulina mixed polypeptides

[0022] (1) Carry out enzymatic hydrolysis of the spirulina protein prepared in Example 1. First, use alkaline protease to hydrolyze the spirulina protein. The enzymatic hydrolysis conditions are: the amount of enzyme added is 4300U / g, the temperature is 55°C, and the pH is 7.0. 160min; after hydrolysis, inactivate the enzyme in a water bath at 85°C for 15-20min.

[0023] (2) The hydrolyzate of step (1) was further hydrolyzed with papain, the enzymolysis conditions were: enzyme-to-substrate ratio 4.5%, temperature 60°C, pH 6.5, enzymolysis 210min. After hydrolysis, inactivate the enzyme in a water bath at 80°C for 15-20 minutes.

[0024] (3) Centrifuge the hydrolyzate obtained in step (2) at 4°C, 5000r / min for 20min, collect the supernatant, freeze-dry to obtain the Spirulina polypeptide.

Embodiment 3

[0025] Example 3 Separation, purification and artificial synthesis of bacteriostatic spirulina polypeptide

[0026] (1) The spirulina mixed polypeptide prepared in Example 2 was subjected to antibacterial experiments, using Escherichia coli and Staphylococcus aureus as the experimental strains to confirm that it has antibacterial activity.

[0027] (2) Separate and purify the mixed polypeptide with antibacterial properties in step (1) using molecular sieves, and use Sephadex G-25 column chromatography to obtain 4 components, and conduct antibacterial experiments on each component , the results showed that component 2 had antibacterial activity.

[0028] (3) The component 2 obtained in step (2) was separated and purified by reverse-phase high-performance liquid chromatography (Zorbax SB-C18 column 4.6mm×250mm), and 4 groups of peaks were obtained. After collection, antibacterial experiments were carried out to obtain Peak 1 has antibacterial activity.

[0029] (4) The peak 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com