A kind of polyphenylene sulfide coil coating

A technology of polyphenylene sulfide and coil coatings, which is applied in the field of roller coating and metal coils, can solve the problems affecting the application of coil coatings, such as high molecular chain rigidity and brittleness, so as to ensure gloss stability and relative Good capacity and overcoming brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 prepares polyphenylene sulfide coil coating 1

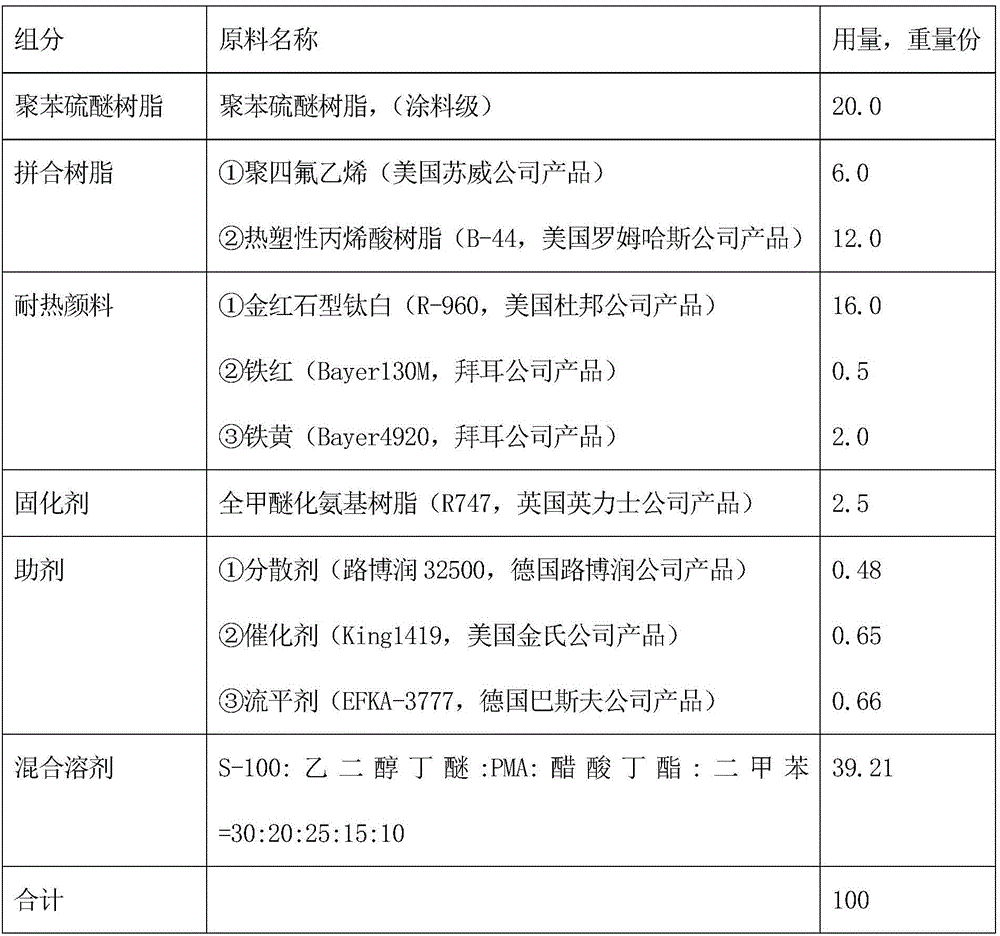

[0021] 1. See Table 1 for the formula.

[0022] Table 1

[0023]

[0024] 2. Preparation method

[0025] ① Prepare raw materials according to the dosage of each component listed in Table 1;

[0026] ② Take 18 parts from the mixed solvent prepared in step ① and add 12 parts of thermoplastic acrylic resin into the reaction bottle, start stirring, heat up to 140°C to dissolve the resin, keep it warm for 3 hours and cool down to get 30 parts of thermoplastic acrylic resin solution, save it for later use;

[0027] ③In the 30 parts of thermoplastic acrylic resin solution obtained in step ②, add the dispersant Lubrizol 32500 and a mixed solvent with a formula volume of 50% and stir evenly, then add the combined resin polytetrafluoroethylene, polyphenylene sulfide resin and heat-resistant Pigments, mixed evenly, and ground to a fineness of ≤20 μm with a sand mill to prepare a color paste;

[0028] ④In the colo...

Embodiment 2

[0029] Embodiment 2 prepares polyphenylene sulfide coil coating 2

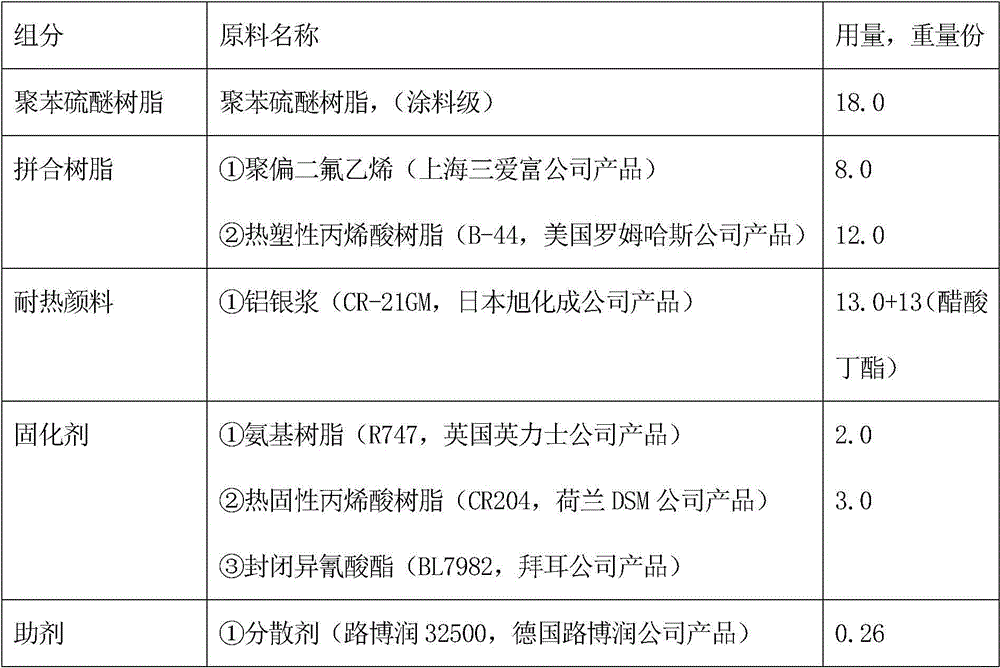

[0030] 1. See Table 2 for the formula.

[0031] Table 2

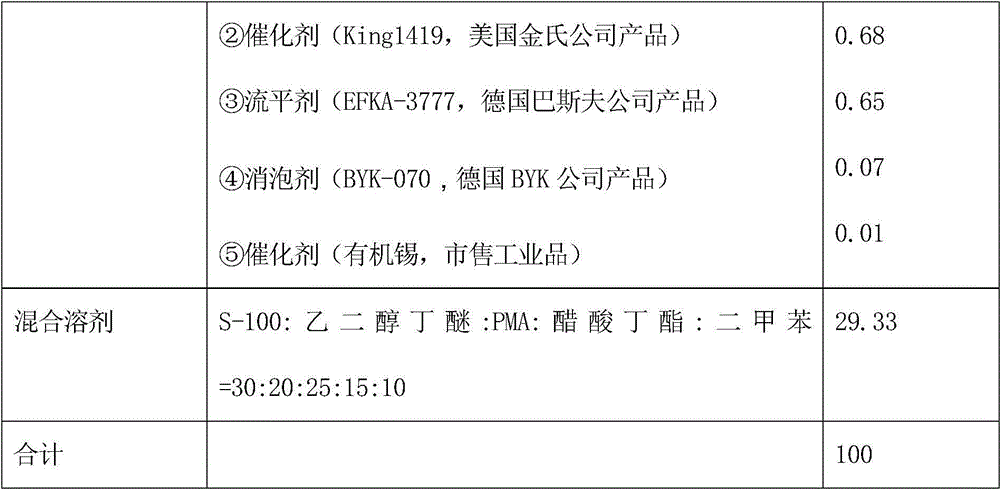

[0032]

[0033]

[0034] 2. Preparation method

[0035] 1. Prepare raw materials according to the consumption of each component described in Table 2;

[0036] ② Take 18 parts from the mixed solvent prepared in step ① and add 12 parts of thermoplastic acrylic resin into the reaction bottle, start stirring, heat up to 140 ℃ to dissolve the resin, keep it warm for 3 hours and then cool down to get 30 parts of thermoplastic acrylic resin solution, save it for later use;

[0037] ③ Soak 13 parts of aluminum silver paste CR-21GM in 13 parts of butyl acetate for 4 hours, and save for later use;

[0038] ④Take 25 parts of combined resin thermoplastic acrylic resin solution obtained in step ②, add dispersant Lubrizol 32500 to it and stir evenly, then add combined resin polyvinylidene fluoride and polyphenylene sulfide resin, mix evenly, and disperse at...

Embodiment 3

[0040] Example 3 Preparation of polyphenylene sulfide coil coating 3

[0041]1. The formula is shown in Table 3.

[0042] table 3

[0043]

[0044] 2. Preparation method

[0045] 1. Prepare raw materials according to the consumption of each component described in Table 3;

[0046] ② Take 18 parts from the mixed solvent prepared in step ① and add 12 parts of thermoplastic acrylic resin into the reaction bottle, start stirring, heat up to 140°C to dissolve the resin, keep it warm for 3 hours and cool down to get 30 parts of thermoplastic acrylic resin solution, save it for later use;

[0047] ③Add the dispersant Lubrizol 32500 and 50% of the mixed solvent of the formula to the 30 parts of blended resin thermoplastic acrylic resin solution obtained in step ② and stir evenly, then add the blended resin polyphenylene sulfide resin and heat-resistant pigments, mix Evenly, use a sand mill to grind to a fineness of ≤20μm to make a color paste;

[0048] ④In the color paste prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com