Method for preparing lanthanum cobaltate-doped nanorod array gas-sensitive sensor

A technology of nanorod array and gas sensor, which is applied in the field of preparation of doped lanthanum cobaltate nanorod array gas sensor, which can solve the problem that the lanthanum cobaltate carbon monoxide gas sensor cannot be used at room temperature, so as to improve the response recovery speed , increase the contact area, improve the effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

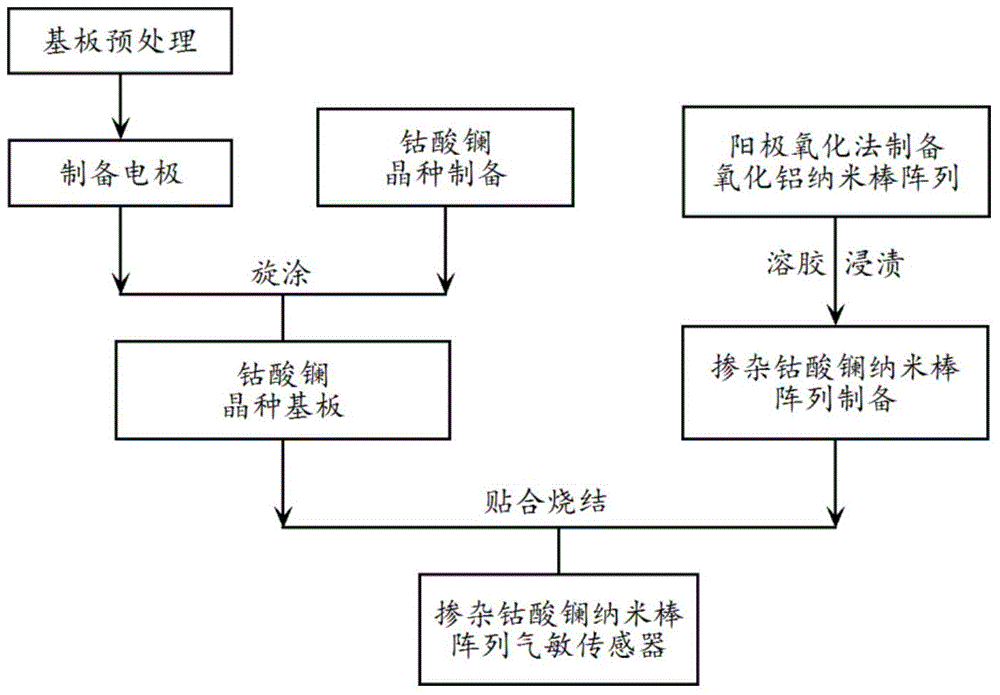

[0014] Such as figure 1 As shown, a method for preparing a doped lanthanum cobaltate nanorod array gas sensor provided by the present invention specifically comprises the following steps:

[0015] (1) Sensor substrate preparation:

[0016] Selected substrates: including silicon substrates, alumina ceramic substrates, glass substrates, preferably silicon substrates. The substrate was ultrasonically washed alternately in ethanol and acetone solutions to remove surface stains, and then the substrate was taken out and placed in deionized water to clean the residual organic solution. The substrate after the above pretreatment is placed in an ion sputtering apparatus, and a layer of metal conductive electrodes, such as gold, silver, platinum, preferably gold, is sputtered by mask lithography to obtain a sensor substrate.

[0017] (2) Preparation of lanthanum cobaltate seed crystals:

[0018] Dissolve cobalt salt and lanthanum salt with a molar ratio of Co / La=(0.8~1.2):1 in deioni...

example 1

[0030] Select a silicon substrate. The silicon substrate was ultrasonically washed three times in ethanol and acetone solutions alternately for 10 minutes each to remove surface stains, and then the substrate was taken out and placed in deionized water to clean the residual organic solution. Put the above-mentioned pretreated substrate into an ion sputtering apparatus, and sputter a layer of gold conductive electrodes by mask photolithography.

[0031] Co(NO 3 ) 2 ·6H 2 O and La(NO 3 ) 3 ·6H 2 Dissolve O in deionized water, then add hydrogen peroxide that is equimolar to Co, then add NaOH to pH = 11 to obtain a precipitate, filter the precipitate and wash with deionized water until pH = 7, dry in an oven at 70°C for 3 hours, and then in a muffle The lanthanum cobaltate nanoparticles were obtained by calcining in a furnace at 600°C for 4 hours. Add the prepared lanthanum cobaltate nanoparticles into ethylene glycol, control the concentration of lanthanum cobaltate to 50g...

example 2

[0036] Select a glass substrate. The glass substrate was ultrasonically washed three times in ethanol and acetone solutions alternately for 10 minutes each to remove surface stains, and then the substrate was taken out and placed in deionized water to clean the residual organic solution. Put the above-mentioned pretreated substrate into an ion sputtering apparatus, and sputter a layer of silver conductive electrodes by mask photolithography.

[0037] CoCl with molar ratio Co / La=1.2 2 ·6H 2 O and LaCl 3 ·7H 2 Dissolve O in deionized water, then add hydrogen peroxide that is equimolar to Co, then add KOH to pH = 12 to obtain a precipitate, filter the precipitate and wash with deionized water to pH = 7, dry it in an oven at 90°C for 1 hour, and then in a muffle The lanthanum cobaltate nanoparticles were obtained by calcining in a furnace at 750° C. for 8 hours. Add the prepared lanthanum cobaltate nanoparticles into isopropanol, control the concentration of lanthanum cobalta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com