Wall body thermal insulation decontamination disinfection flame retardant plant fiber and preparation method thereof

A plant fiber and wall technology is applied in the field of plant fibers for thermal insulation, decontamination, disinfection and flame retardant of walls and the field of preparation thereof. Material saving and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

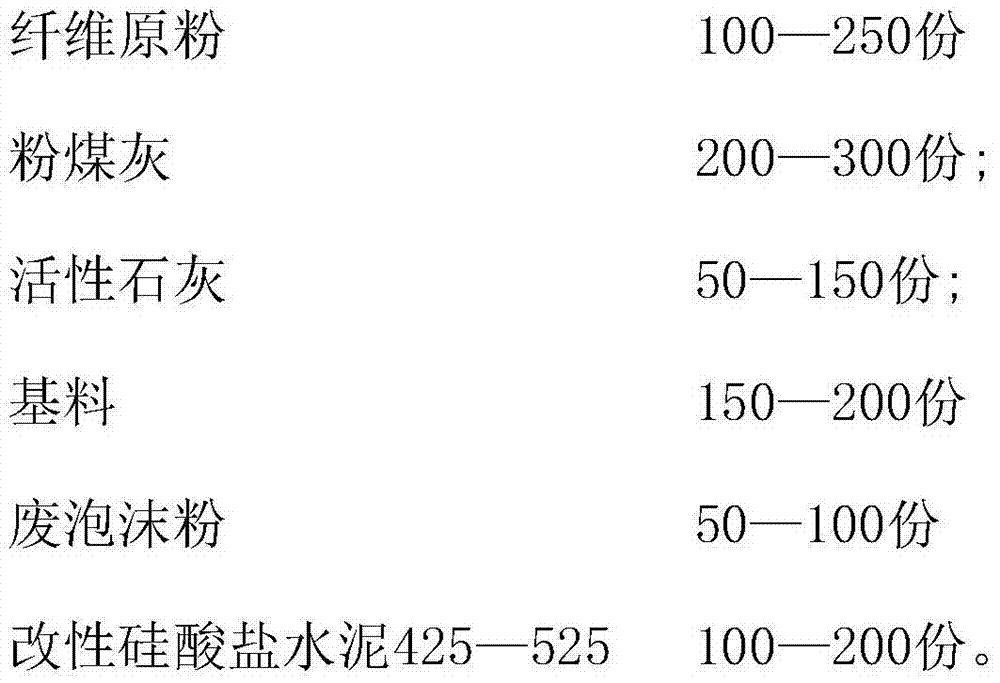

Method used

Image

Examples

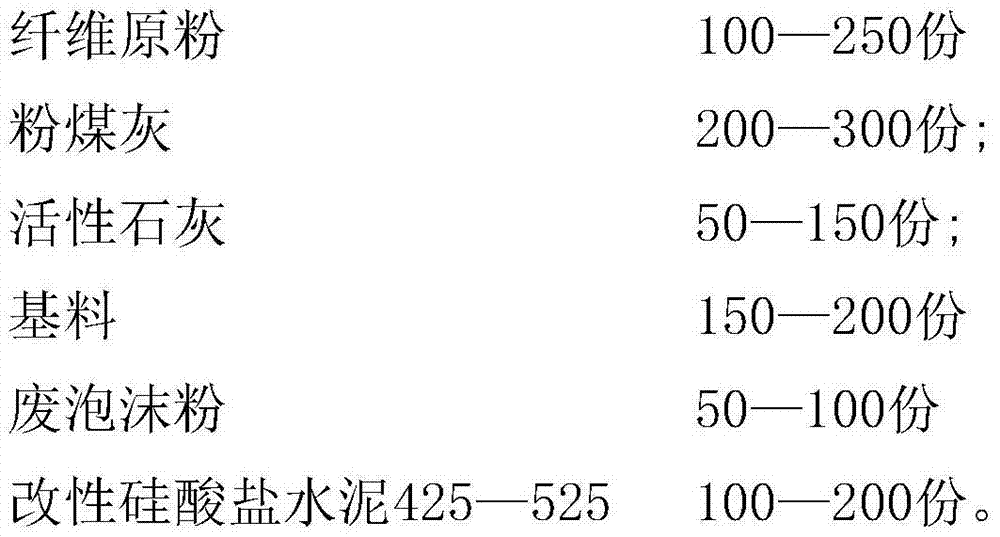

Embodiment 1

[0014] 200 parts of raw fiber powder, 200 parts of vermiculite powder, 70 parts of modified lime, 300 parts of fly ash, 150 parts of modified Portland cement, and 80 parts of foam powder (80 mesh fineness).

[0015] The above-mentioned ingredients are put into a mixer and mixed evenly to prepare the plant fiber for heat preservation, decontamination, disinfection and flame retardancy of the wall. When using, add 450 parts of water and stir it into a paste. It is used in the inner wall for heat preservation, high strength, and waterproof. The wall decoration does not need to be leveled with putty, and the wall base does not need to be mortared. On the surface level, the adsorption and decontamination properties of the ingredients can absorb indoor chemical organic matter and convert it into harmless substances through sodium ion reaction to protect the indoor environment; it is waterproof, flame retardant, light in weight, and has high adhesion.

Embodiment 2

[0017] 250 parts of raw fiber powder, 200 parts of fly ash, 200 parts of diatomaceous earth, 100 parts of activated lime, 200 parts of modified Portland cement, and 50 parts of foam powder.

[0018] The above-mentioned components are put into a mixer and mixed evenly to prepare the plant fiber for heat preservation, decontamination, disinfection and flame retardant of the wall. When using, add 400 parts of water and stir it into a paste. It is used for external wall insulation. It can reduce cement-based wall surface varnish and use waterproof paint on the insulation layer. It is firmly bonded and has high strength. Do not use it for putting on putty. It can be used directly on the insulation layer. In terms of environmental protection, this product has a strong ion transfer performance, and has a strong adsorption performance on organic pollution in the atmosphere and harmful gases and dust particles emitted by traffic vehicles.

Embodiment 3

[0020] 150 parts of raw fiber powder, 300 parts of fly ash, 200 parts of activated clay, 150 parts of activated lime, 150 parts of modified Portland cement, and 50 parts of (50 mesh fineness) foam.

[0021] The above-mentioned components are put into a mixer and mixed evenly to prepare the plant fiber for heat preservation, decontamination, disinfection and flame retardant of the wall. When using, add 350 parts of water, stir evenly for 7-8 to dry, transfer to the mold of the plate making machine, extrude, dry, remove the bottom plate, stack, sprinkle water for 10-15 days, and then leave the factory. Used in wall construction, it is light in weight, heat and sound insulation, flame retardant, eliminates the pollution emitted by adsorbed wall coatings and chemical materials, and purifies the environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com