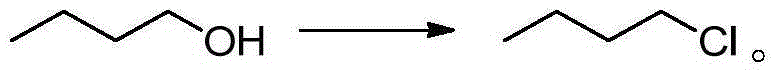

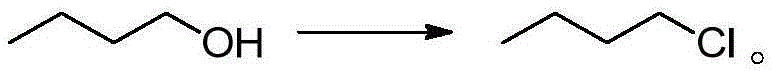

A kind of preparation method of 1-chlorobutane

A technology of chlorobutane and hydrogen chloride, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of unfavorable industrialized production, long post-processing time, and high production costs, and achieves short post-processing time and cost. Low, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] After adding concentrated hydrochloric acid (33.5% by mass, 653.0 g, 6.0 mol) and dimethyl sulfoxide (0.31 g, 0.004 mol) into a four-neck round bottom flask, stir at 20-30°C for 30 min. Add n-butanol (149.0g, 2.0mol), slowly raise the temperature to 90°C-100°C, and distill while reacting. As the reaction time prolongs, fractions will slowly distill out gradually. After about 20hrs of heat preservation distillation and reaction, almost no If any fraction was further distilled, the reaction was considered to be complete. After the obtained fractions were separated, the upper organic layer was 1-chlorobutane, and finally 170.3 g of 1-chlorobutane was obtained, with a yield of 91.5% and a GC purity of 99.7%.

Embodiment 2

[0033]After implementing 1 reaction, finally get the reaction liquid raffinate 531.0g, continuously pass into HCl gas wherein, after passing through for a period of time, sampling detection, HCl content is 34.6%, stop passing into HCl gas, at this moment, after passing through HCl The total weight of the reaction liquid raffinate is: 654.1g. After adding 0.1 g of dimethyl sulfoxide, stir at 20-30°C for 30 min. Add n-butanol (149.0g, 2.0mol), slowly raise the temperature to 90-100°C, and distill while reacting. As the reaction time prolongs, fractions will gradually distill out. After about 20hrs of heat preservation distillation and reaction, almost no Fractions were further distilled, and the reaction was considered to be complete. After the obtained fractions were separated, the upper organic layer was 1-chlorobutane, and finally 172.5 g of 1-chlorobutane was obtained, with a yield of 92.7% and a GC purity of 99.6%.

Embodiment 3

[0035] Water (434.3g) was added into the four-neck round bottom flask, and HCl gas was continuously fed thereinto, so that the HCl content reached 45%, and the total weight of the reaction solution was 789.6g. Dimethylsulfoxide (0.78g, 0.01mol) was added and stirred at 15-20°C for 20min. Add n-butanol (149.0g, 2.0mol), slowly raise the temperature to 85-95°C, and distill while reacting. As the reaction time prolongs, fractions will gradually distill out. After 20hrs of heat-retaining distillation and reaction, there is almost no fraction After further distillation, the reaction was considered to be complete. After the obtained fractions were separated, the upper organic layer was 1-chlorobutane, and finally 174.7 g of 1-chlorobutane was obtained, with a yield of 93.5% and a GC purity of 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com