Producing technology of benzotriazole-typed ultraviolet absorber

A technology of benzotriazoles and production process, applied in the field of ultraviolet absorber production, can solve problems such as poor operating environment, secondary pollution of products, high labor intensity, etc., and achieve the advantages of improving purity, saving reducing agent, and improving operating environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

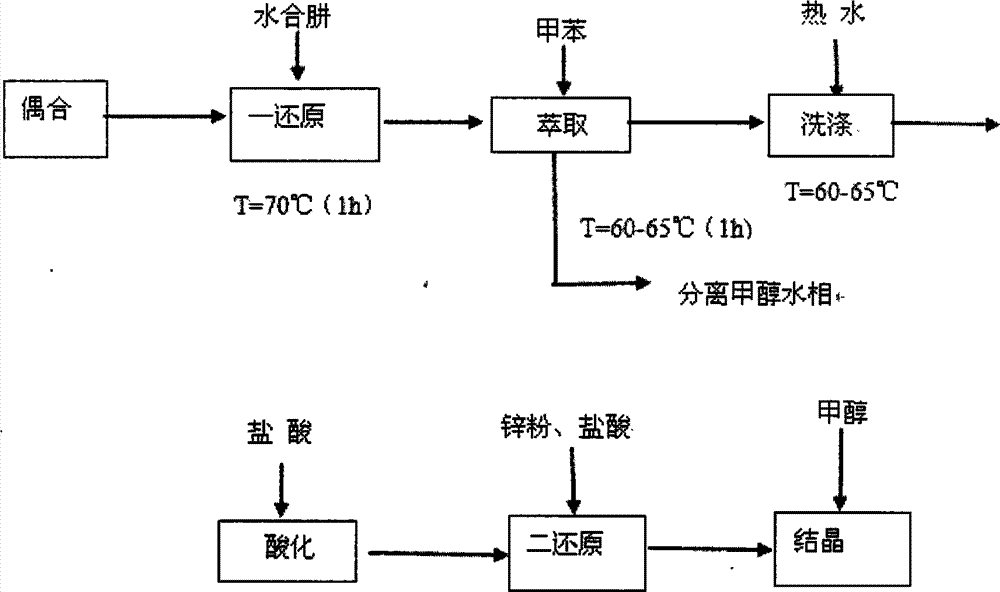

[0020] 1. Mix and stir 135KG of o-nitroaniline, 300L of concentrated hydrochloric acid with a concentration of 31%, and 300L of water, heat the mixed liquid to 75°C, and cool down to 0°C;

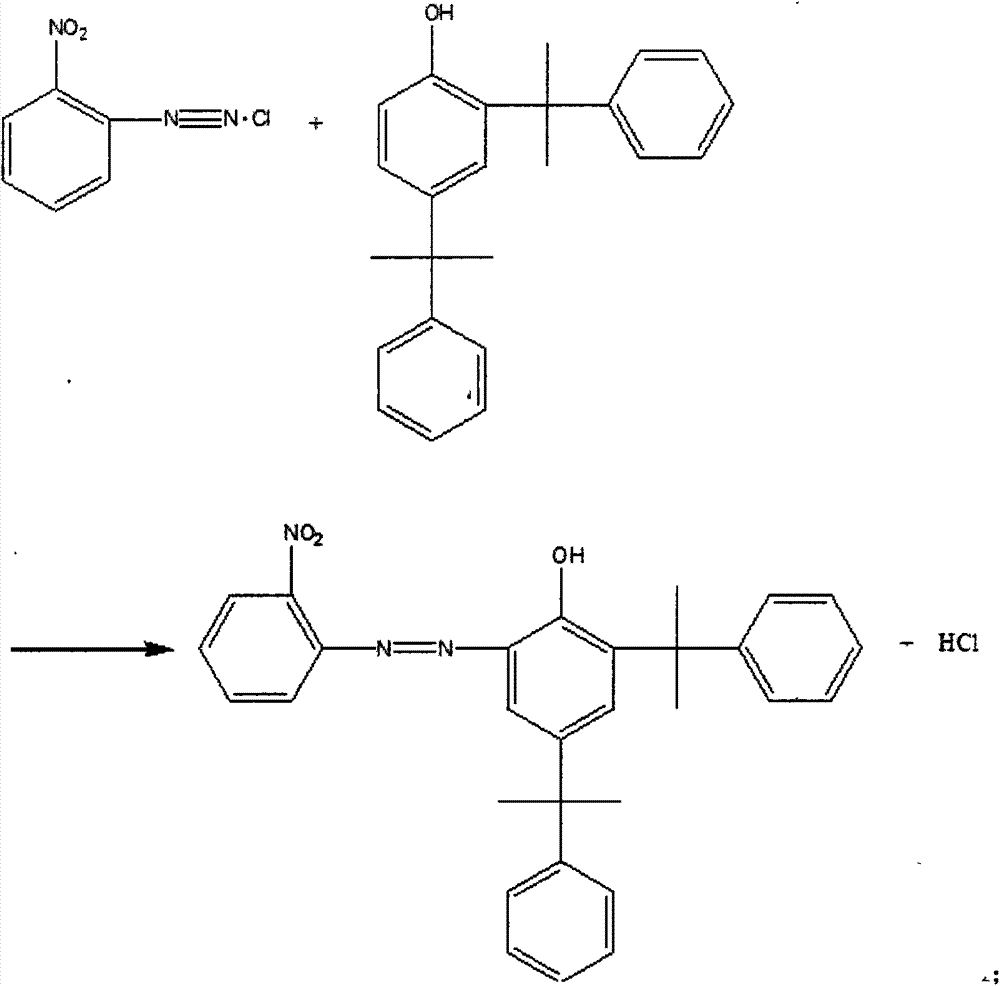

[0021] 2. Add a solution made of 80KG of sodium nitrite and 160L of water to the above liquid, mix and stir, add 10KG of sulfamic acid, and then mix the obtained diazonium solution with 300KG of 2,4 dicumylphenol in alkaline methanol solution. Coupling, its chemical reaction equation is:

[0022]

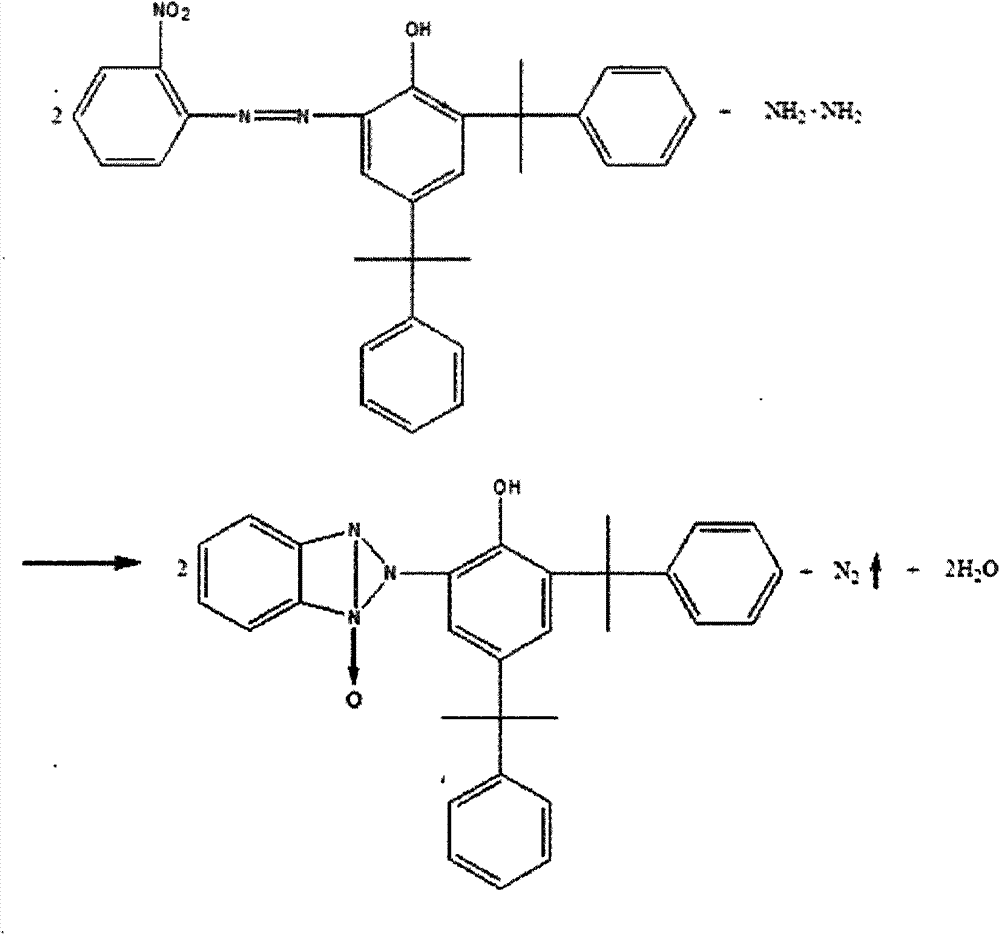

[0023] 3. After the coupling is completed, directly add 40KG of hydrazine hydrate for a reduction. At this time, the heating temperature is 70°C, and the heating time is 1 hour;

[0024] 4. Add 400L of toluene after the first reduction, heat to 60-65°C for 1 hour, separate the aqueous phase of methanol through extraction, and recover methanol through rectification. The chemical reaction equation is:

[0025]

[0026] 5. Wash the remaining solvent layer with hot water, heat it to 60-65°C, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com