Esterification method of catechin or tea polyphenol

A technology for tea polyphenols and catechins, applied in the field of esterification of catechins or tea polyphenols, can solve the problems of difficult separation, low acylation ability of carboxylic acids, weak activity of carboxylic acids and phenols, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

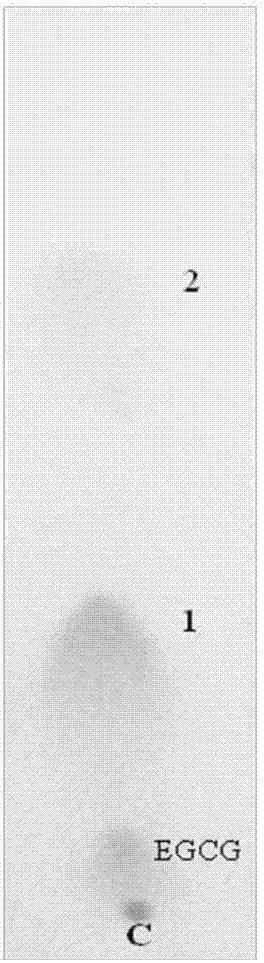

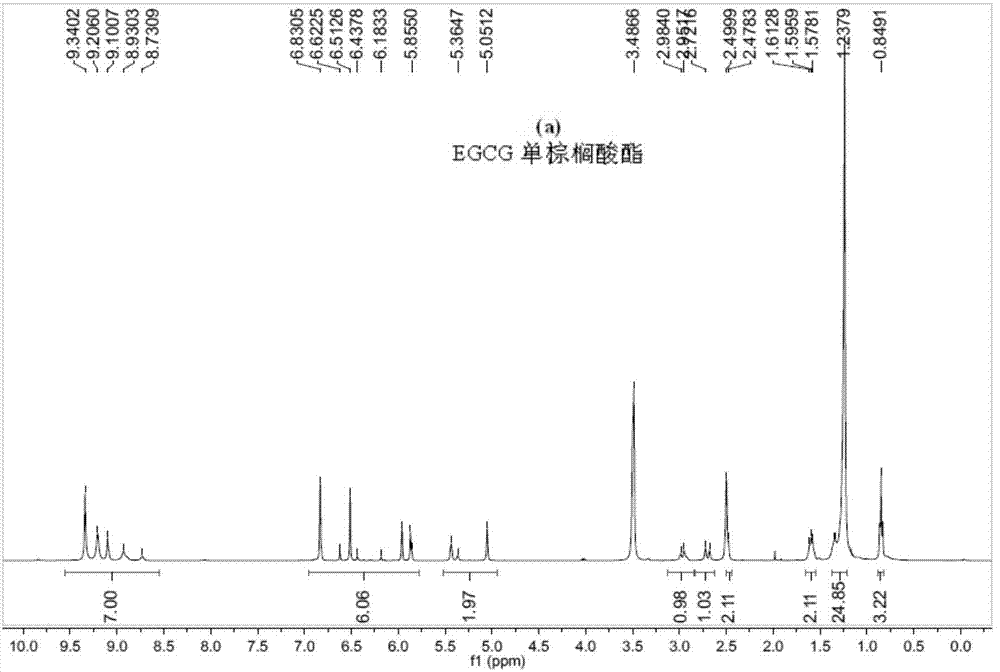

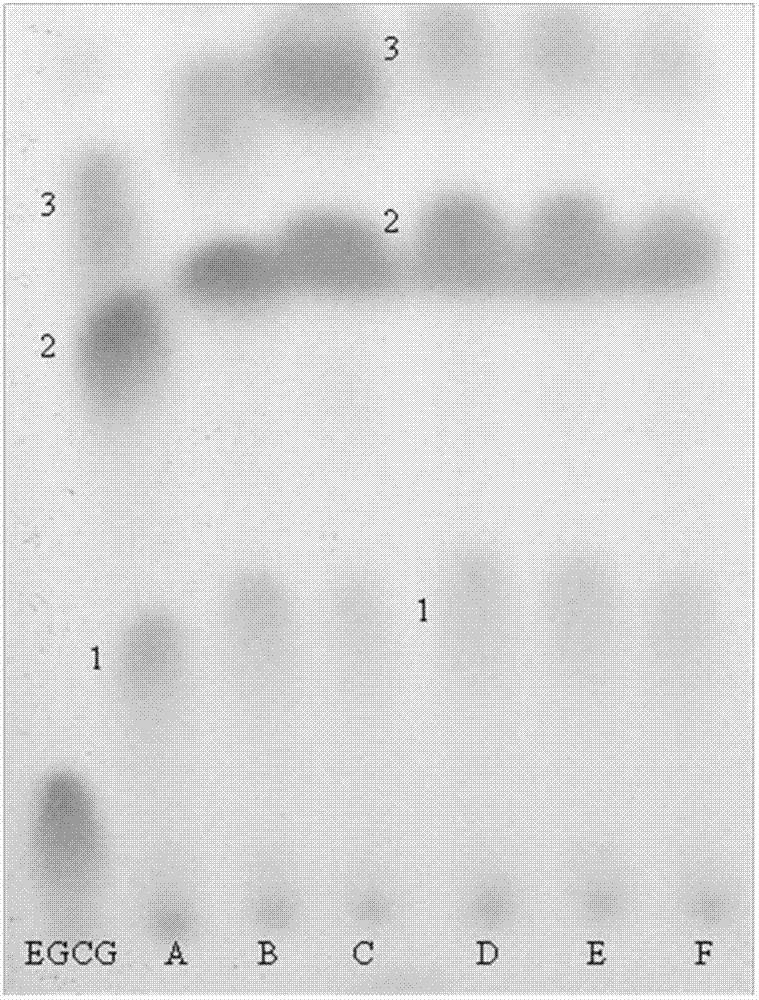

Image

Examples

Embodiment 1

[0083] Dissolve 1.78g (11mmol) of CDI in 50mL of ethyl acetate, add 0.60g (10mmol) of acetic acid, heat to reflux, and stir the reaction until no gas is released. Solution is cooled to 60 ℃, adds 0.47g (1.0mmol) EGCG (purity 97%, the same below), under N 2 Under protection, continue to heat and reflux for 2 hours. Cool to room temperature, add 50mL of 0.5M HCl, stir for 2min, separate to remove the water phase, wash with 2×50mL (represents washing twice, each time 50mL, the same below) saturated brine, dry over anhydrous sodium sulfate, filter, The solvent was removed by rotary evaporation, and the obtained solid was recrystallized from ethanol-water to obtain 0.76 g of a white solid after drying. The H-NMR analysis result was consistent with the EGCG peracetate reported in the literature, and the yield was 96%.

Embodiment 2

[0085] Dissolve 2.09g (11mmol) of 1,1□-carbonylbis(2-methylimidazole) in 50mL of tetrahydrofuran, add 0.60g (10mmol) of acetic acid, heat to reflux, and stir the reaction until no gas is released. Cool the solution to 60°C, add 0.47g (1.0mmol) EGCG, and 2 Under protection, continue to heat and reflux for 2 hours. Cool to room temperature, add 1.5M HCl dropwise with stirring until the pH of the solution is about 2, continue to add 100mL distilled water dropwise, filter with suction, and wash with water until neutral. The resulting solid was recrystallized from tetrahydrofuran-water, and dried in vacuo to obtain 0.75 g of EGCG peracetate as a white solid, with a yield of 94%.

Embodiment 3

[0087] 1.0g (14.7mmol) imidazole and 0.47g (1.0mmol) EGCG were dissolved in 30mL acetone, in N 2 Under protection, a 20 mL acetone solution containing 1.1 g (14 mmol) of acetyl chloride was added dropwise, and the reaction was stirred. After the dropwise addition was completed, it was heated to reflux, and the stirring reaction was continued for 2 hours. Cool to room temperature, add 10mL of 0.1M HCl, then dropwise add 150mL of distilled water under stirring, filter with suction, wash with water until neutral, and dry in vacuo. The obtained solid was separated and purified by silica gel column chromatography (ethyl acetate / petroleum ether 3:1, v / v) to obtain 0.78 g of EGCG peracetate as a white solid, with a yield of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com