Preparation method of cationic waterborne polyurethane resin with high solid content

A water-based polyurethane and cationic technology, applied in the field of coatings, can solve problems such as the demand for polluting organic solvents, less isocyanate varieties, and narrow raw material sources, and achieve the effect of reducing the amount of finishing agents, firm adhesion, and soft, natural and plump appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Polyester (Mn=1000), Ymer TM Add N120, 1,8-octanediol, and triethanolamine into the reactor for mixing, and vacuum dehydrate at 0.05MPa, 107°C for 1h;

[0039] 2) Remove the vacuum, pass nitrogen protection, start to add toluene diisocyanate dropwise at 60°C, finish dropping for 1 hour and keep warm for 1 hour;

[0040] 3) Add dibutyltin dilaurate, lower the temperature to 50°C, start to add N-methyldiethanolamine dropwise, keep the temperature for reaction after 1h dropwise addition, measure the content of NCO until the content of isocyanate reaches the theoretical end point of 4.7%;

[0041] 4) Neutralize with glacial acetic acid to pH 6-7 at 40°C;

[0042] 5) Add deionized water at 40°C and stir at high speed to disperse, add ethylenediamine to extend the chain for 30 minutes, and remove acetone under reduced pressure to obtain a light yellow and relatively clear cationic waterborne polyurethane resin.

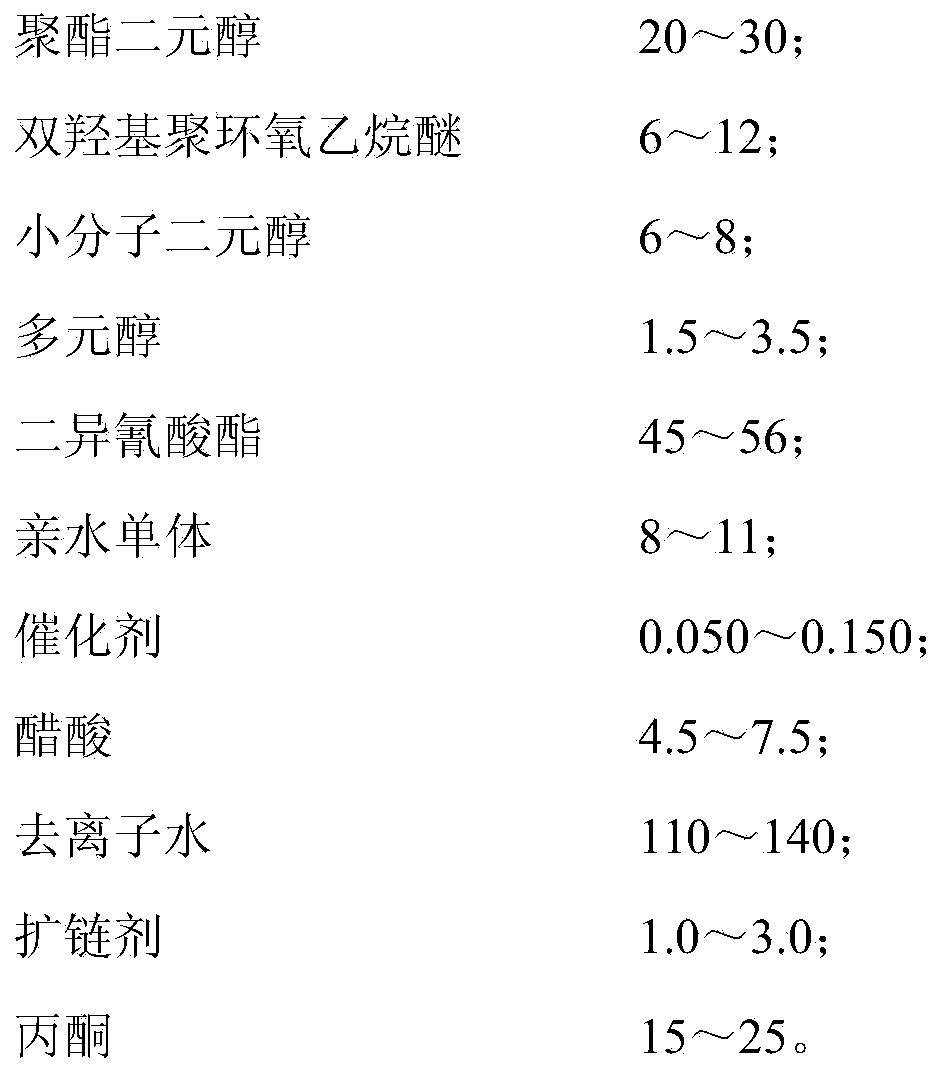

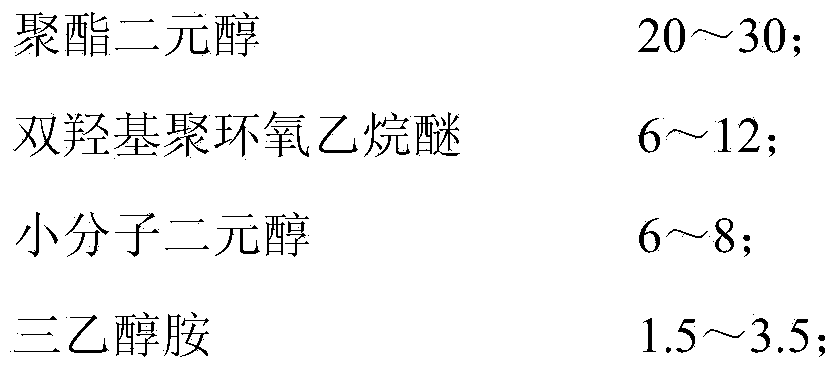

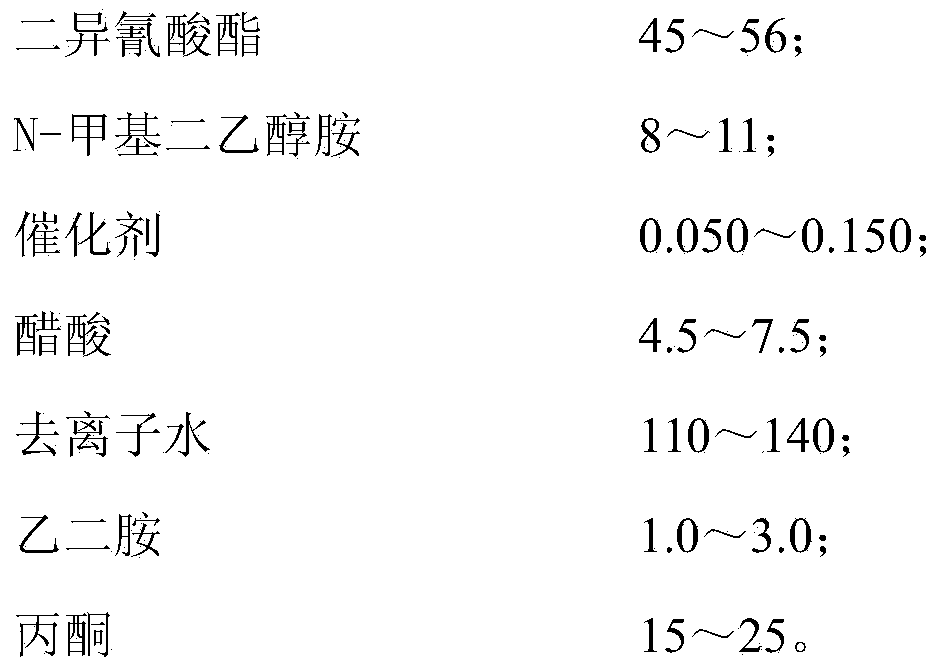

[0043] Wherein the raw material of various raw materials u...

Embodiment 2

[0048] 1) Polycarbonate diol (Mn=2000), Ymer TM Add N120, 1,4-butanediol, and triethanolamine into the reactor for mixing, and vacuum dehydrate at 0.05MPa, 107°C for 1h;

[0049] 2) Remove the vacuum, pass nitrogen protection, start to add toluene diisocyanate dropwise at 60°C, finish dropping for 1 hour and keep warm for 1 hour;

[0050] 3) Add dibutyltin dilaurate, lower the temperature to 50°C, start to add N-methyldiethanolamine dropwise, keep the temperature for reaction after 1h dropwise addition, measure the content of NCO until the content of isocyanate reaches the theoretical end point of 6.57%;

[0051] 4) Neutralize with glacial acetic acid to pH 6-7 at 40°C;

[0052] 5) Add deionized water at 40°C and stir at high speed to disperse, add ethylenediamine to extend the chain for 30 minutes, and remove acetone under reduced pressure to obtain a light yellow and clear waterborne polyurethane resin with high cationic content.

[0053] Wherein the raw material of various ...

Embodiment 3

[0058] 1) Polyester (Mn=1000), Ymer TM Add N120, 1,4-butanediol, and triethanolamine into the reactor for mixing, and vacuum dehydrate at 0.05MPa, 107°C for 1h;

[0059] 2) Remove the vacuum, pass nitrogen protection, start to drop toluene diisocyanate at 65°C, finish dropping for 1 hour and keep warm for 1 hour;

[0060] 3) Add dibutyltin dilaurate, lower the temperature to 50°C, start to add N-methyldiethanolamine dropwise, keep the temperature for reaction after 1h dropwise addition, measure the content of NCO until the content of isocyanate reaches the theoretical end point of 6.492%;

[0061] 4) Neutralize with acetic acid to pH 6-7 at 40°C;

[0062] 5) Add deionized water at 40°C and stir at high speed to disperse, add ethylenediamine to extend the chain for 30 minutes, and remove acetone under reduced pressure to obtain a light yellow and relatively clear cationic waterborne polyurethane resin.

[0063] Wherein the raw material of various raw materials used is (by wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com