Silicon nitride anti-reflection film for crystalline silicon solar cell and preparation method thereof

A solar cell, silicon nitride reduction technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problem that the photoelectric conversion efficiency cannot achieve the maximum improvement, the film layer design cannot achieve the anti-reflection efficiency, and special gas multi-process Process and other issues, to achieve the effect of facilitating large-scale commercial production, improving cell efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

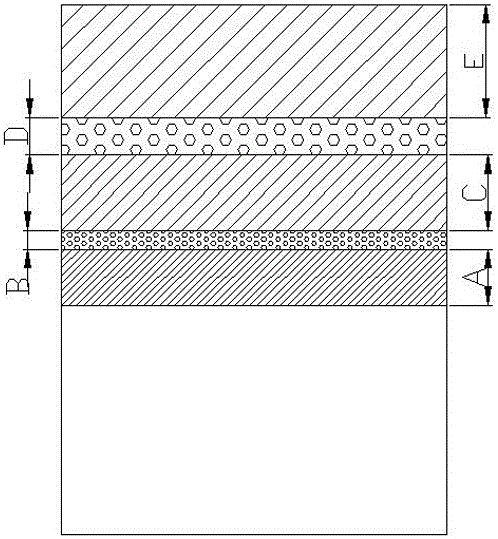

[0025] A method for preparing a silicon nitride antireflection film for a crystalline silicon solar cell, comprising the steps of:

[0026] 1) Clean the silicon substrate after phosphorus diffusion to ensure that the surface of the silicon wafer has good hydrophobicity and is clean and free of water stains.

[0027] 2) Insert the cleaned silicon substrate into the graphite boat according to the conventional method, put it into the quartz tube of the PECVD equipment, then vacuumize the quartz tube and raise the temperature to 450°C, and keep the temperature at 480S.

[0028] 3) When the equipment is evacuated below 10 mttor, inject 5800 SCCM of NH into the quartz tube after evacuation of the PECVD equipment 3 Gas, and keep the pressure in the quartz tube at 1800 mttor, keep the constant pressure for 1-2min, set the power of the high frequency power supply to 6000W, turn on the high frequency power supply, and keep the NH 3 The flow rate of the gas is constant, and the NH3 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com