Core-shelled structured lithium ion battery positive composite material and its preparation method

A lithium-ion battery and composite material technology, applied in the field of lithium-ion battery positive electrode material preparation, can solve the problems of metal ions being far apart, reducing electron mobility, and being unsuitable for charging and discharging, achieving high specific capacity and energy density, and improving battery life. Effect of chemical properties, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

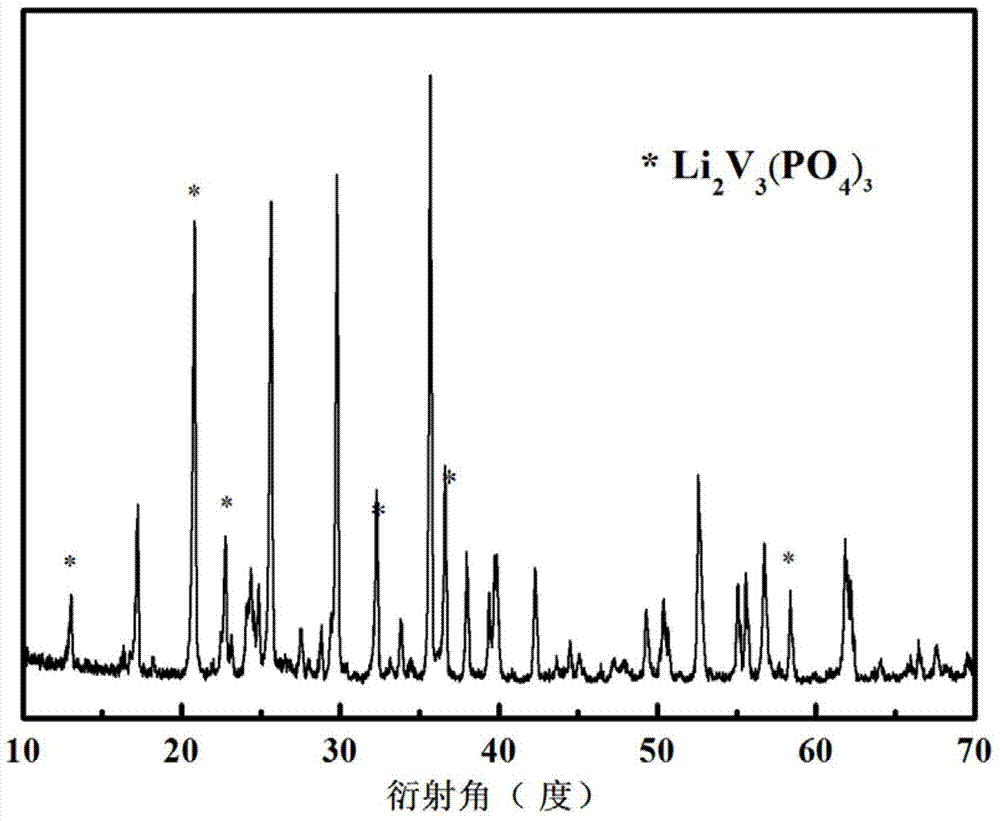

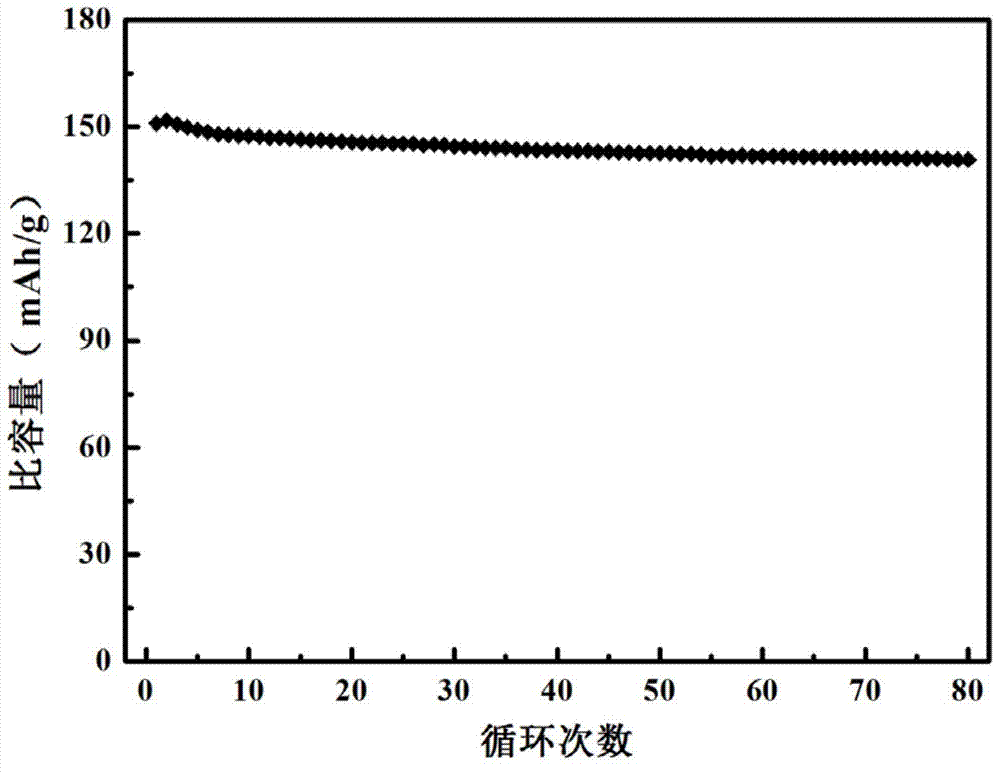

[0032] A core-shell structure lithium ion battery cathode composite material, including LiFePO 4 Nano core and Li 3 V 2 (PO4) 3 Shell, Li 3 V 2 (PO4) 3 The shell is evenly coated in LiFePO 4 The periphery of the nano-nucleus, and Li 3 V 2 (PO4) 3 The outer periphery of the shell is also coated with amorphous carbon. The chemical formula of the core-shell structure lithium ion battery cathode composite material is xLiFePO 4 ·Li 3 V 2 (PO 4 ) 3 / C, where the value of x ranges from 3 to 9, and the mass percentage of amorphous carbon in the positive electrode composite material of the lithium ion battery is 3 to 15%.

[0033] XLiFePO with the above core-shell structure 4 ·Li 3 V 2 (PO 4 ) 3 / C lithium ion battery cathode composite material is prepared by the following preparation method:

[0034] (1) Weigh FeSO as the raw material according to the stoichiometric ratio of 8:1:11:6:27 4 ·7H 2 O, V 2 O 5 , NH 4 H 2 PO 4 , Li 2 CO 3 And H 2 C 2 O 4 ·2H 2 O. Weigh Ketjen superconducting carb...

Embodiment 2

[0040] A core-shell structure of xLiFePO 4 ·Li 3 V 2 (PO 4 ) 3 The preparation method of / C lithium ion battery cathode composite material includes the following steps:

[0041] (1) Weigh FeSO as the raw material according to the stoichiometric ratio of 8:1:11:6:27 4 ·7H 2 O, V 2 O 5 , NH 4 H 2 PO 4 , Li 2 CO 3 And H 2 C 2 O 4 ·2H 2 O. Weigh Ketjen superconducting carbon black at a mass ratio of 10% of the amorphous carbon in the cathode composite material of the lithium ion battery, mix the weighed raw materials into a closed container, and then add 300ml to the closed container. Ionized water, magnetically stirred at 70℃ for 2h to obtain a solid-liquid mixture;

[0042] Carry out ultrasonic dispersion treatment on the obtained solid-liquid mixture, the treatment time is 2h;

[0043] (2) Open the closed container or transfer the obtained solid-liquid mixture into an open container to continue heating and stirring for 12 hours to obtain a dry gel precursor mixture;

[0044] (3) Grind ...

Embodiment 3

[0048] A core-shell structure of xLiFePO 4 ·Li 3 V 2 (PO 4 ) 3 The preparation method of / C lithium ion battery cathode composite material includes the following steps:

[0049] (1) Weigh FeSO as the raw material according to the stoichiometric ratio of 8:1:11:6:27 4 ·7H 2 O, V 2 O 5 , NH 4 H 2 PO 4 , Li 2 CO 3 And H 2 C 2 O 4 ·2H 2 O. Weigh Ketjen superconducting carbon black at a mass ratio of 10% of the amorphous carbon in the cathode composite material of the lithium ion battery, mix the weighed raw materials into a closed container, and then add 300ml to the closed container. Ionized water, magnetically stirred at 70℃ for 2h to obtain a solid-liquid mixture;

[0050] Carry out ultrasonic dispersion treatment on the obtained solid-liquid mixture for a treatment time of 2 hours, then transfer it to a hydrothermal kettle and keep it at 200°C for 6 hours;

[0051] (2) Open the closed container or transfer the obtained solid-liquid mixture into an open container to continue heating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com