Polymer dispersed liquid crystal type light control body using nickel-based electrode, and manufacturing method thereof

A technology for dispersing liquid crystals and polymers, which is used in optical elements, optics, nonlinear optics, etc. to change the spectral characteristics of emitted light, and can solve the problems of increasing energy consumption, unfavorable effects, blocking or absorbing heat rays, etc. problems, to achieve cost reduction, excellent blocking effect, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

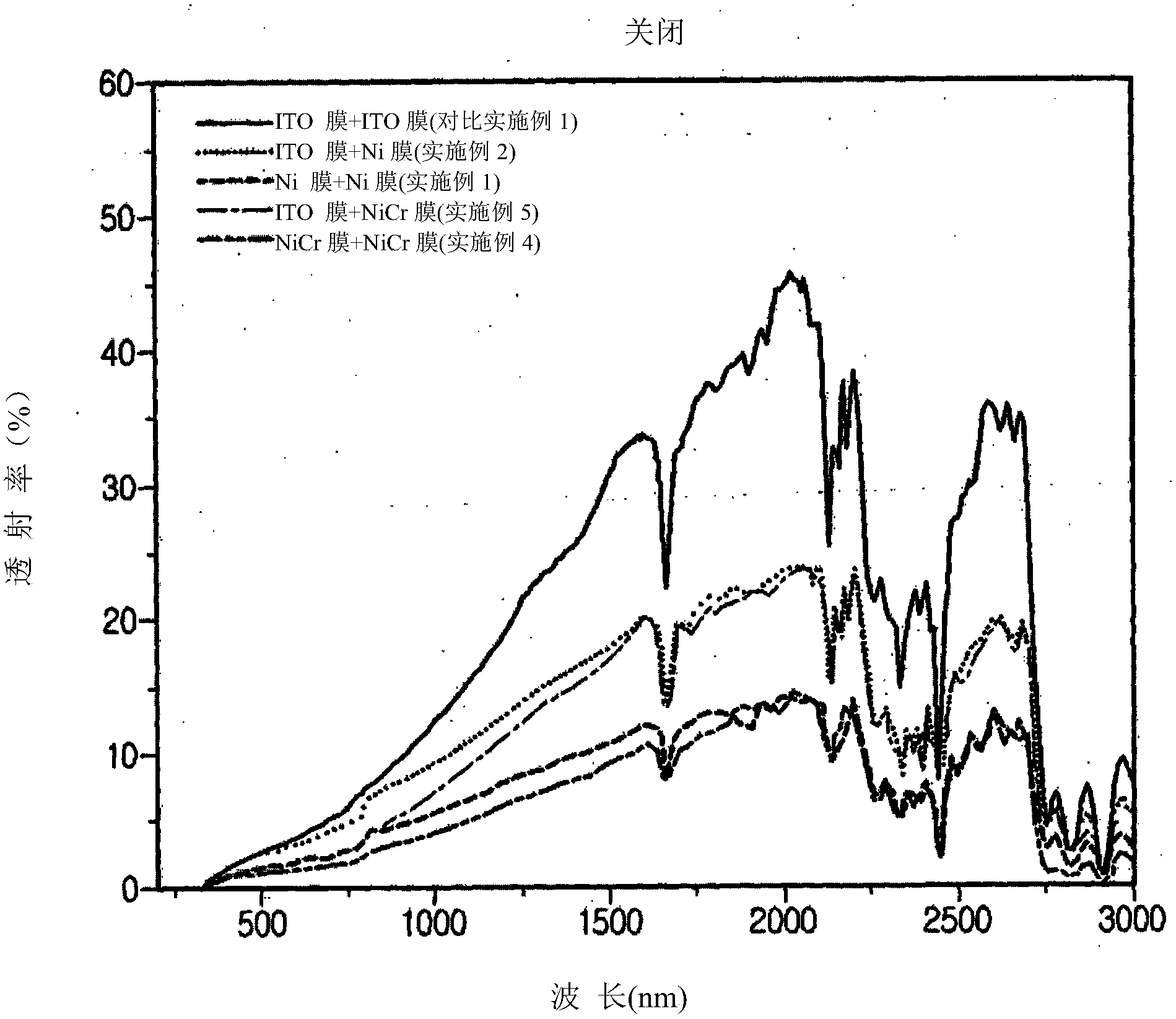

Embodiment 1

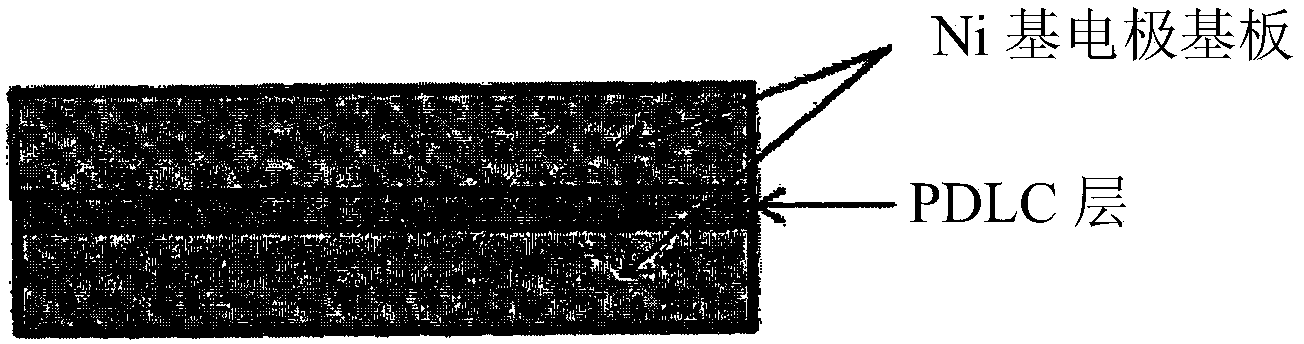

[0050] Embodiment 1: the preparation of the photocontrol body comprising Ni deposition substrate (film base)-PDLC layer-Ni deposition substrate (film base)

[0051] (1) Formation of Ni-deposited PET film for PDLC type photocontrol body

[0052] For the thermal deposition of SiO on a 188 μm thick PET film 2 Buffer layer, using an evaporation system, coated containing 99.99% granular SiO 2 of evaporative substances. For thermal deposition, the internal vacuum of the evaporator chamber was set to 1.3x10 using a roughing rotary pump -3 Torr, then using a booster pump and a high vacuum oil diffusion pump, keep it at 3.0x10 -5 support. To remove organic matter from the test sample before deposition and to enhance the adhesion between the substance and the test sample during deposition, 15 sccm of Ar and 25 sccm of O were introduced 2 , so as to perform ion beam treatment on the substrate. In SiO 2 During thermal deposition, the SiO 2 The deposition rate is maintained at an...

Embodiment 2

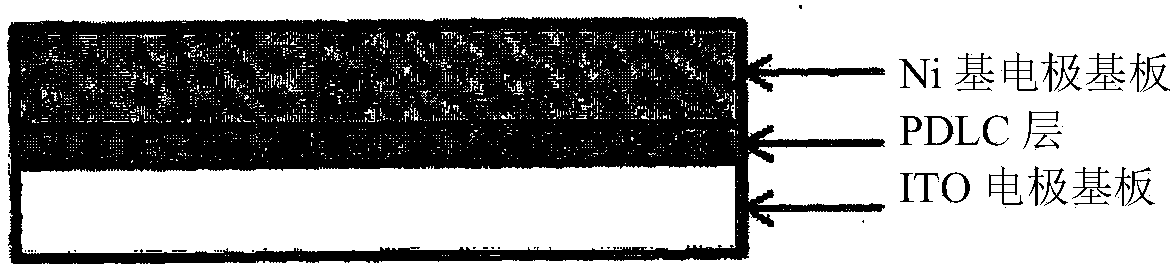

[0058] Embodiment 2: the preparation of the photocontrol body comprising Ni deposition substrate (film base)-PDLC layer-ITO deposition substrate (film base)

[0059] Prepare the PDLC type photocontrol body in the same manner as in Example 1, the difference is that two electrode substrates are opposite to each other, one is the Ni electrode substrate of Example 1, and the other is an ITO deposited electrode film purchased from Japan Toray ( By depositing tin oxide (SnO) doped with 10wt% on the PET film substrate 2 ) of indium oxide (InO 3 ), and satisfy the visible light transmittance of 88% and the sheet resistance of 100Ω / □ at 550nm).

[0060] Specifically, the liquid crystal dispersion composition was coated to a thickness of 20 μm on one side of the Ni electrode substrate, and then an ITO-deposited electrode film of Toray was stacked thereon. Subsequently, using a 365nm metal halide lamp (UV intensity: 75mW / cm 2 , UV energy: 1050mJ / cm 2 ) light source, the light with a ...

Embodiment 3

[0061] Embodiment 3: the preparation of the photocontrol body comprising Ni deposition substrate (film base)-PDLC layer-Ni-Cr alloy deposition substrate (film base)

[0062] Prepare the PDLC type photocontrol body in the same manner as in Example 1, except that two electrode substrates are opposite to each other, one is the Ni electrode substrate of Example 1, and the other is a Ni-Cr alloy electrode substrate (at 550nm The visible light transmittance is 44%, the near-infrared transmittance at 2000nm is 37%, and the sheet resistance is 195Ω / □), the Ni-Cr alloy electrode substrate uses a content ratio (weight ratio) of Ni and Cr of 8 : 2 targets instead of Ni targets, obtained in the same way as in Example 1.

[0063] Specifically, the liquid crystal dispersion composition was applied to a thickness of 20 μm on one side of the Ni electrode substrate, and then the Ni—Cr alloy electrode substrate was stacked thereon. Subsequently, using a 365nm metal halide lamp (UV intensity: 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com