Backsheet for eco-friendly photovoltaic cell module and method for manufacturing same

A photovoltaic module and backplane technology, applied in the direction of photovoltaic power generation, chemical instruments and methods, applications, etc., can solve the problems of poor bonding strength of substrates, increased raw material costs, and non-environmental protection, so as to improve productivity and product quality, and reduce explosions and fire risk, the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The water-dispersed composition for preparing the fluororesin layer by an in-line coating process during the preparation of the substrate may contain a crystalline fluoropolymer, a pigment, a water-dispersed binder, and water.

[0039] In the water dispersion composition, the fluoropolymer may function to improve durability and weather resistance. In an exemplary embodiment of the present application, when the water dispersion composition is used to form a fluororesin layer, a crystalline fluoropolymer is used instead of a non-crystalline fluoropolymer. This is because, in non-crystalline fluoropolymers, urethane bonds are formed by reacting with curing agents and provide good initial bond strength, but may be hydrolyzed under conditions of high temperature and high humidity, resulting in less Crystalline fluoropolymers have low bonding reliability.

[0040] The crystalline fluoropolymer may have a crystallinity of 55% or less, 50% or less, 10% to 55%, or 10% to 50%. ...

Embodiment 1

[0112] Preparation of Water Dispersion Compositions

[0113] 20g of acrylate-modified polyester resin (polyethylene terephthalate (PET), glycidyl methacrylate (GMA) in molar ratio=1:0.5:1:0.2 ), in the form of an aqueous dispersion of a copolymer of methyl methacrylate (MMA) and methacrylic acid (MAA), Na + Used as the counter ion of MAA in aqueous dispersion, solid content: 30%), 5 g of acrylate copolymer containing oxazoline groups (WS-500, solid content: 40%) as crosslinking agent, Nippon Shokubai Co., Ltd.) and 50 g of titanium dioxide (Tipure TS6200, DuPont) as a pigment were added to 500 g of polyvinylidene fluoride resin (solid content: 20%) dispersed in water as an emulsion, and dispersed using a stirrer to prepare a water dispersion combination.

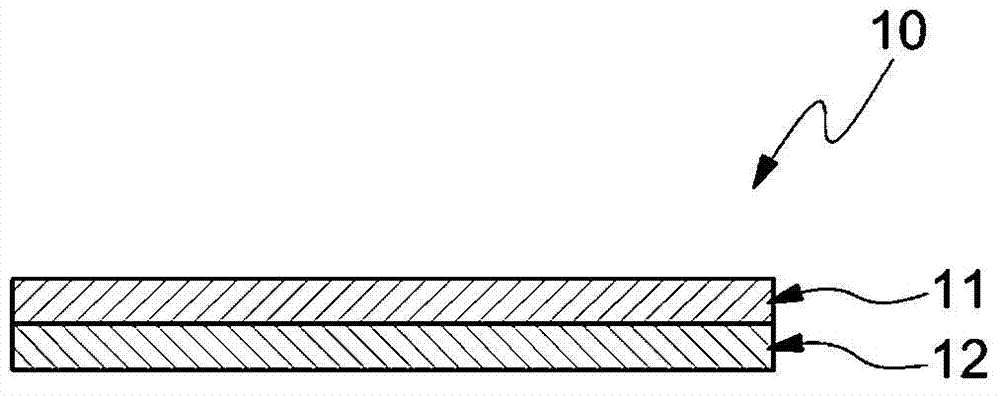

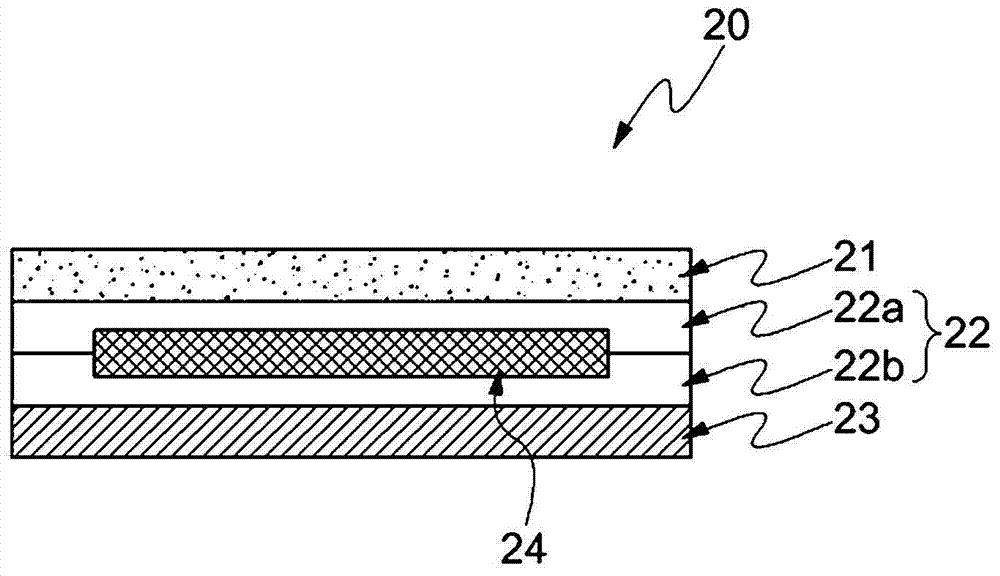

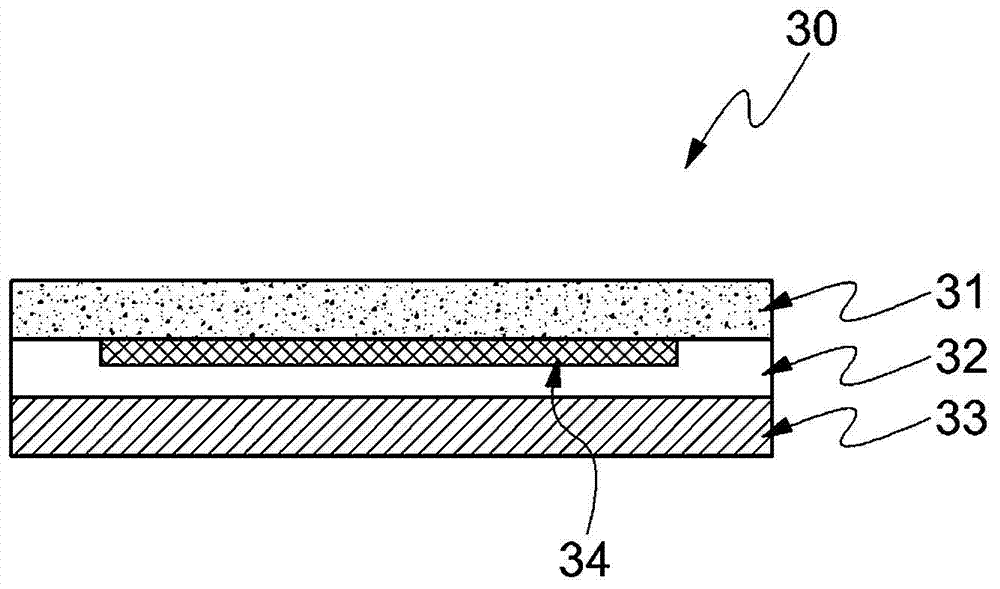

[0114] Preparation of backsheets for photovoltaic modules

[0115] Unoriented polyethylene terephthalate having a thickness of 2500 μm was obtained from melt-extruded polyethylene terephthalate after injecting fully dried...

Embodiment 2

[0117] In addition to using 5g of hexamethoxymelamine (Cyme1301, CYTEC company) as a crosslinking agent to replace the acrylate copolymer containing oxazoline groups used in the preparation of the water dispersion composition in Example 1, as implemented A back sheet for a photovoltaic module was prepared as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com