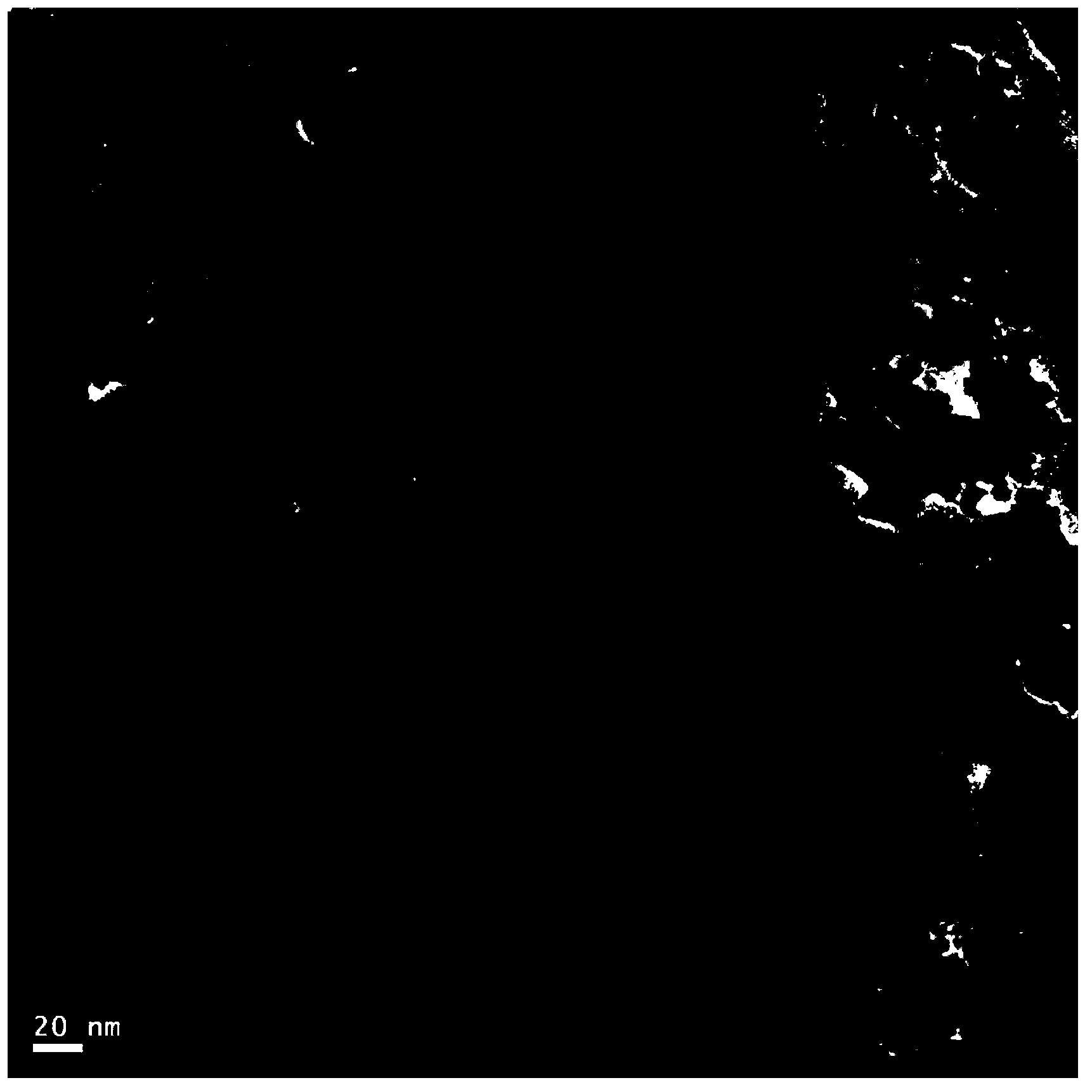

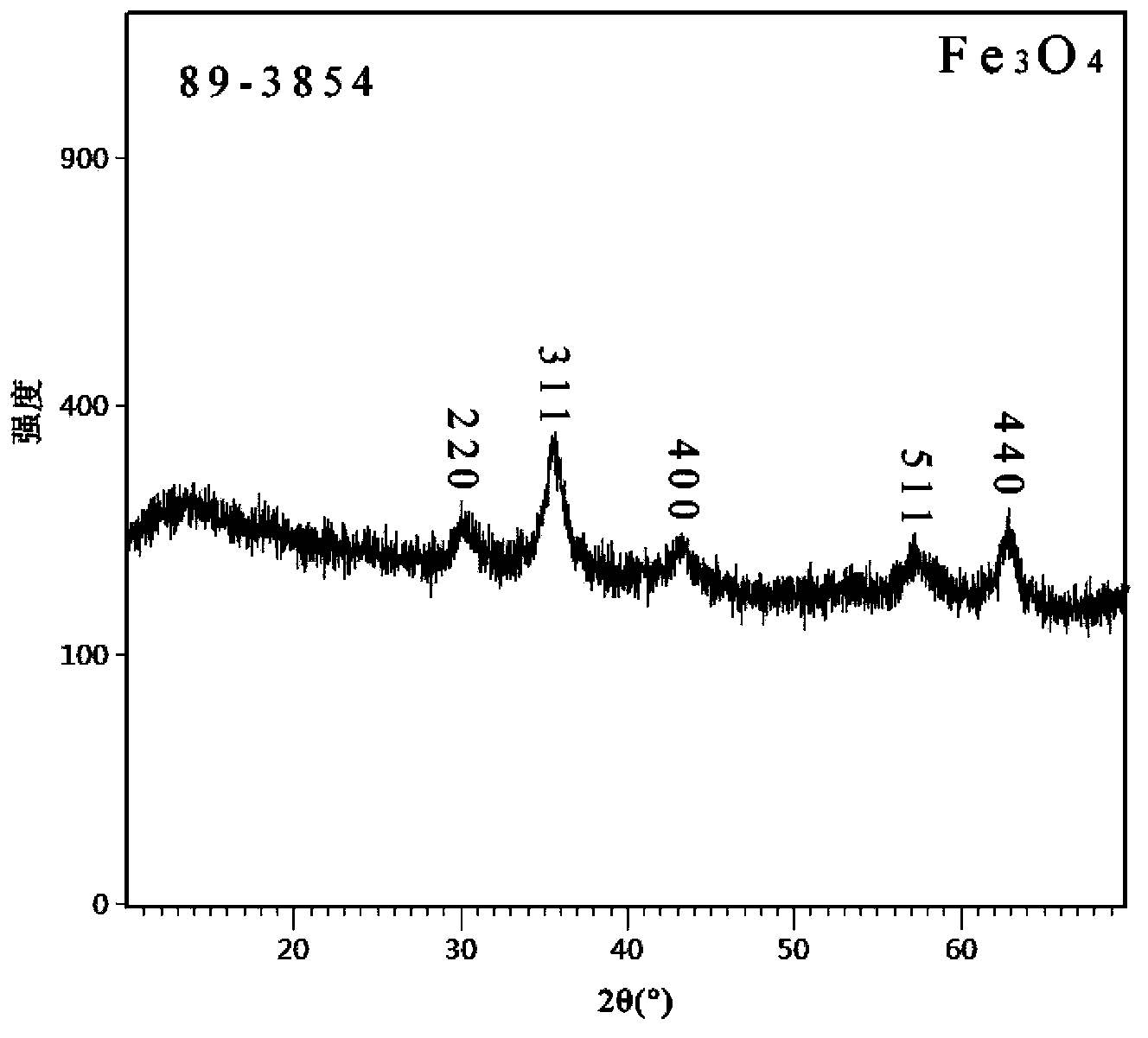

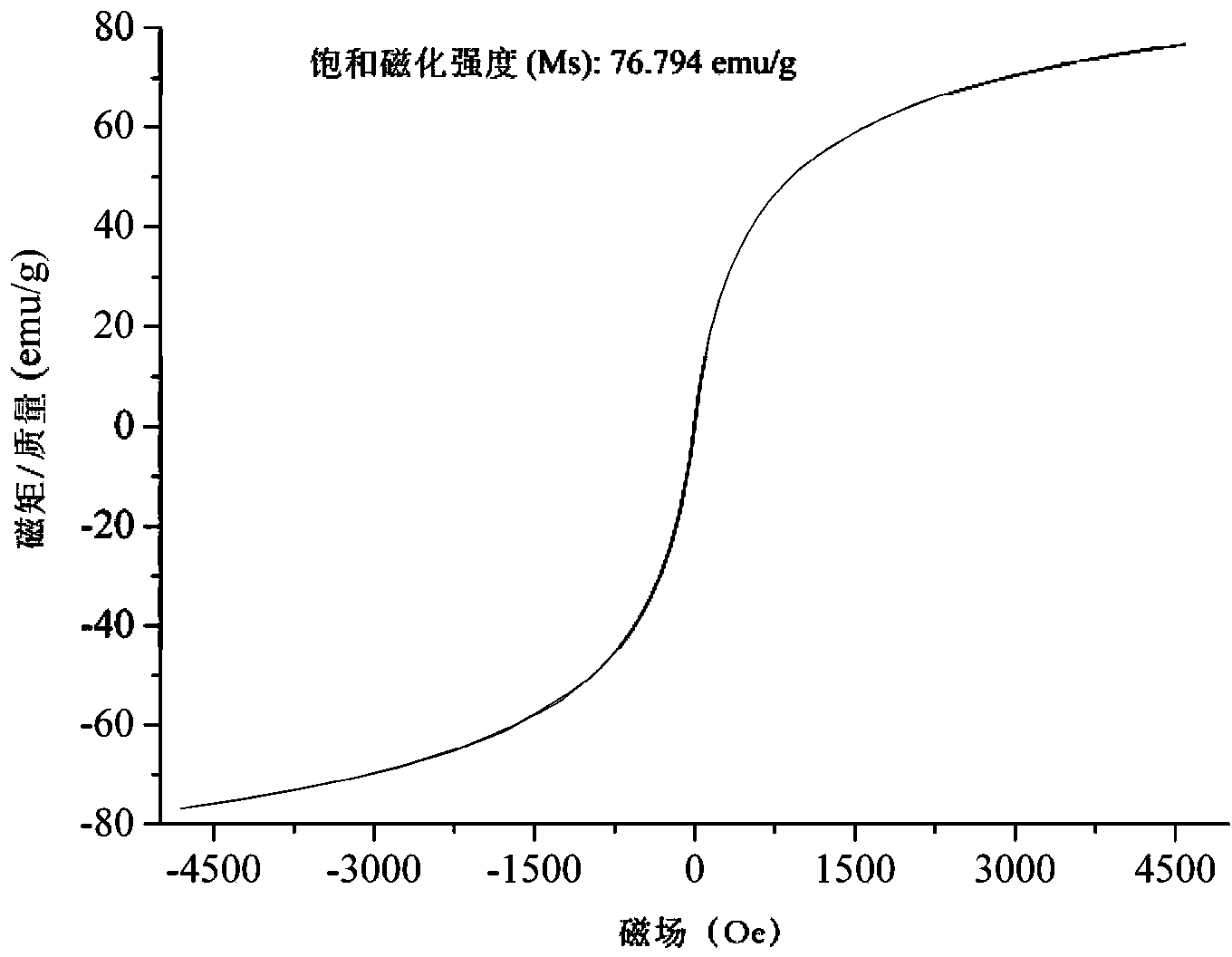

Method for synthesizing superparamagnetic ferroferric oxide nano-sheets

A ferric tetroxide, superparamagnetic technology, applied in the direction of iron oxide/iron hydroxide, nanotechnology, ferrous oxide, etc., can solve the problems of complex process, harsh reaction requirements, large size, etc. Simple conditions, easy to operate, simple to operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for synthesizing superparamagnetic ferric oxide nanosheets, the steps are as follows:

[0020] (1) At room temperature, add trivalent soluble iron salt (ferric chloride) and divalent soluble iron salt (ferrous sulfate) to a certain amount of hydrochloric acid, then add a certain amount of water to prepare a mixed solution of a certain concentration, The mixed solution requires magnetic stirring for several hours to form a uniform mixed solution, wherein the molar ratio of trivalent soluble iron salt to divalent soluble iron salt is 5:1, and the molar ratio of trivalent soluble iron salt to divalent soluble iron salt to hydrochloric acid 4:2:1, and the molar ratio of hydrochloric acid to water is 1:140.

[0021] (2) the mixed solution that step (1) obtains is added dropwise in the 0.5mol / L NaOH solution that contains a certain amount of oleic acid under the vigorous stirring of magnetic stirrer, and the mol ratio of oleic acid and sodium hydroxide is 1: 20, The...

Embodiment 2

[0026] A method for synthesizing superparamagnetic ferric oxide nanosheets, the steps are as follows:

[0027] (1) At room temperature, add trivalent soluble iron salt (ferric sulfate) and divalent soluble iron salt (ferrous sulfate) to a certain amount of hydrochloric acid, and then add a certain amount of water to prepare a mixed solution with a certain concentration. The mixed solution requires magnetic stirring for several hours to form a uniform mixed solution, wherein the molar ratio of trivalent soluble iron salt to divalent soluble iron salt is 3:2, and the molar ratio of trivalent soluble iron salt, divalent soluble iron salt and hydrochloric acid is 8:4:3, the molar ratio of hydrochloric acid to water is 1:120.

[0028] (2) the mixed solution that step (1) obtains is added dropwise in the 2.0mol / L NaOH solution that contains a certain amount of oleic acid under the vigorous stirring of magnetic stirrer, and the mol ratio of oleic acid and sodium hydroxide is 1: 50, ...

Embodiment 3

[0030] A method for synthesizing superparamagnetic ferric oxide nanosheets, the steps are as follows:

[0031] (1) At room temperature, add trivalent soluble iron salt (ferric thiocyanate) and divalent soluble iron salt (ferrous sulfate) to a certain amount of hydrochloric acid, and then add a certain amount of water to prepare a mixed solution of a certain concentration , the mixed solution requires magnetic stirring for several hours to form a uniform mixed solution, wherein the molar ratio of trivalent soluble iron salt to divalent soluble iron salt is 3:1, and the molar ratio of trivalent soluble iron salt, divalent soluble iron salt and hydrochloric acid The ratio is 8:4:2.5, and the molar ratio of hydrochloric acid to water is 1:130.

[0032] (2) the mixed solution that step (1) is obtained is added dropwise in the 1.5mol / L NaOH solution that contains a certain amount of oleic acid under the vigorous stirring of magnetic stirrer, and the mol ratio of oleic acid and sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com