Organic silicon modified phenyl emulsion pressure-sensitive adhesive with high release force and low residue as well as preparation method thereof and application

A silicone, low-residue technology, used in adhesives, adhesive types, ester copolymer adhesives, etc., which can solve the problems of easy hydrolysis of silicone monomers, unstable system cohesion, and large differences in reactivity ratios. , to avoid hydrolysis and self-condensation, ensure mechanical stability, and achieve the effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

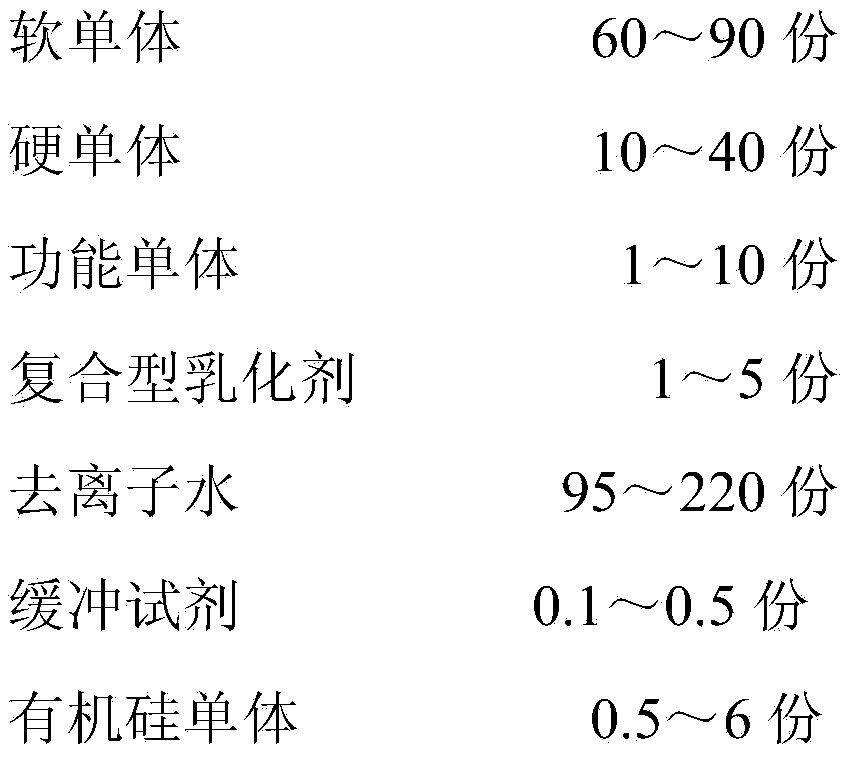

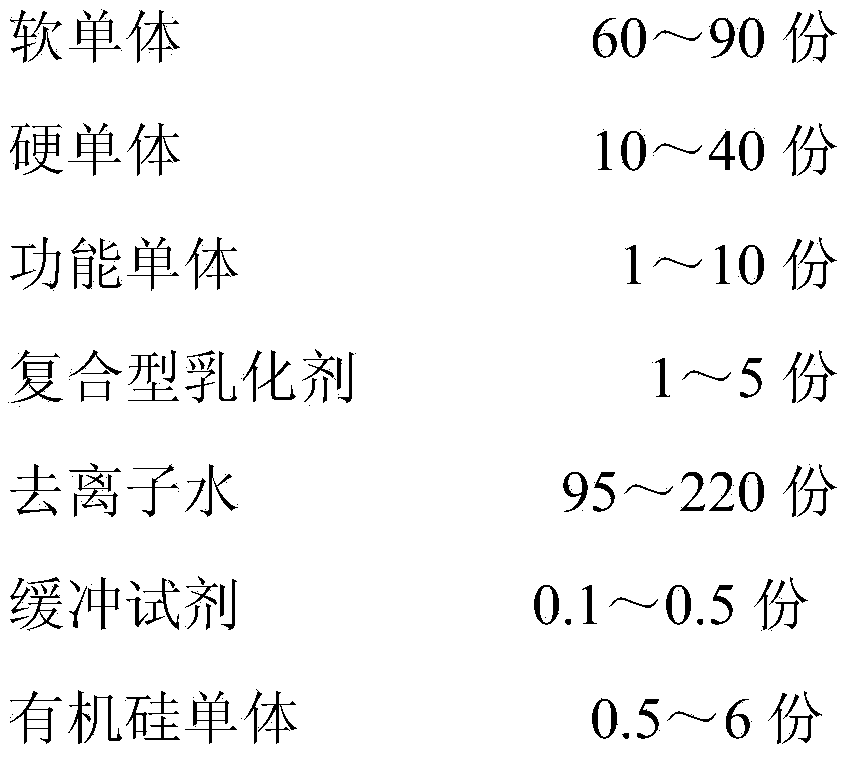

Method used

Image

Examples

Embodiment 1

[0034] Weigh 32.8g of butyl acrylate, 32.8g of isooctyl acrylate, 1.6g of acrylic acid, 3.6g of hydroxypropyl acrylate, 5.2g of methyl methacrylate, and 4g of styrene, and mix them evenly to obtain a mixed monomer; mix 48ml of water, 0.8 Add g2-acrylamido-2-methylpropanesulfonic acid, 1.06g sodium dodecyl sulfate (SDS), 0.54g octylphenol polyoxyethylene ether (OP-10) into the pre-emulsification bottle and stir to dissolve, add For a good monomer mixture, pre-emulsify for 30 minutes under stirring at 10000r / min to obtain a pre-emulsion.

[0035] Add 26ml of water to a four-neck flask, add aqueous sodium bicarbonate solution (0.2g of sodium bicarbonate dissolved in 10ml of water), protect it with nitrogen, put it in an oil bath at 65°C, and measure about 1 / 8 by volume with a graduated cylinder After adding the pre-emulsion, stir at a speed of 260 rpm, raise the temperature to 70°C, add an aqueous initiator solution (0.3g potassium persulfate is dissolved in 10ml water), and cont...

Embodiment 2

[0040] Weigh 35.5g of butyl acrylate, 35.5g of isooctyl acrylate, 1.6g of acrylic acid, 3.6g of hydroxypropyl acrylate, 2.2g of methyl methacrylate, and 1.7g of styrene, and mix them evenly to obtain a mixed monomer; mix 48ml of water, Add 1.6g of 2-acrylamido-2-methylpropanesulfonic acid, 0.53g of sodium dodecyl sulfate (SDS), and 0.27g of octylphenol polyoxyethylene ether (OP-10) into the pre-emulsification bottle and stir to dissolve, add The weighed mixed monomer was pre-emulsified for 40 minutes under stirring at 6000r / min to obtain a pre-emulsion.

[0041] Add 26ml of water into the four-neck flask, add aqueous sodium bicarbonate solution (0.2g of sodium bicarbonate dissolved in 10ml of water), protect it with nitrogen, put it in an oil bath at 70°C, and measure about 1 / 8 by volume with a graduated cylinder After adding the pre-emulsion, stir at a speed of 100 rpm, raise the temperature to 80°C, add an aqueous initiator solution (0.3g potassium persulfate dissolved in 10...

Embodiment 3

[0046] Weigh 35.5g of butyl acrylate, 35.5g of isooctyl acrylate, 1.6g of acrylic acid, 3.6g of hydroxypropyl acrylate, 2.2g of methyl methacrylate, and 1.7g of styrene, and mix them evenly to obtain a mixed monomer; mix 48ml of water, Add 1.2g of 2-acrylamido-2-methylpropanesulfonic acid, 0.8g of sodium dodecyl sulfate (SDS), and 0.4g of octylphenol polyoxyethylene ether (OP-10) into the pre-emulsification bottle and stir to dissolve. Add the weighed mixed monomer, and pre-emulsify for 20 minutes under stirring at 8000r / min to obtain a pre-emulsion.

[0047] Add 26ml of water into the four-neck flask, add aqueous sodium bicarbonate solution (0.2g of sodium bicarbonate dissolved in 10ml of water), protect it with nitrogen, put it in an oil bath at 70°C, and measure about 1 / 8 by volume with a graduated cylinder After adding the pre-emulsion, stir at a speed of 600 rpm, raise the temperature to 80°C, add an aqueous initiator solution (0.3g potassium persulfate dissolved in 10ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com