A kind of preparation method and structure of LED film chip with remelting layer

A thin-film chip and thin-film technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems affecting chip yield and reliability, chip follow-up process rupture, single chip bulging, etc., to achieve low cost and improve optoelectronic performance. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

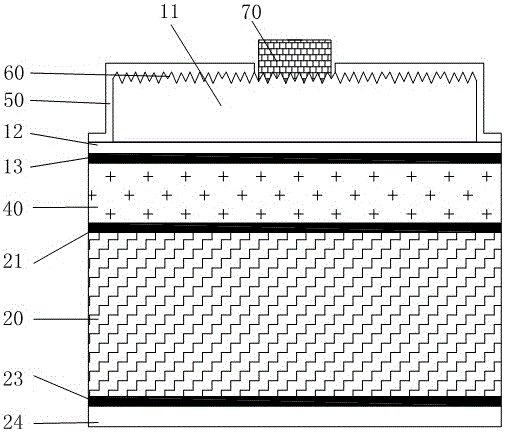

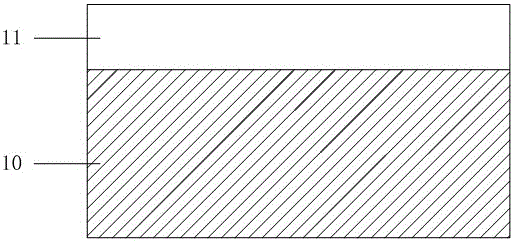

[0053] (1): if figure 2As shown, a substrate 10 is provided on which an LED thin film 11 is grown, wherein the LED thin film 11 includes a buffer layer, an n-type layer, a light emitting layer and a p-type layer. Preferably, the substrate 10 is sapphire, and the LED thin film is an aluminum gallium indium nitrogen thin film obtained by metal chemical vapor deposition (MOCVD). In other embodiments of the present invention, the substrate 10 can also be any one of Si, SiC, GaN, GaAs or AlN, and the LED thin film 11 is not limited to the aluminum gallium indium nitrogen thin film, and can also be other Semiconductor thin films that require stress release, such as aluminum gallium indium phosphide epitaxial films on gallium arsenide substrates.

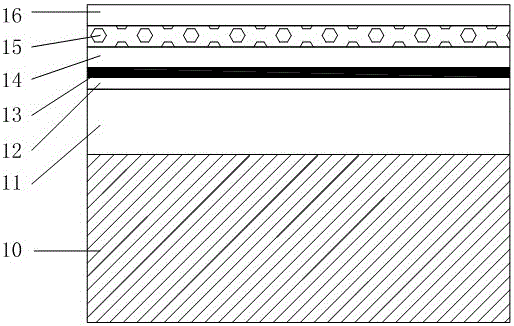

[0054] (2): As shown in FIG. 3 , a reflective contact layer 12 , a barrier layer 13 , a dilution protection layer 14 , a remelting layer 15 and a first bonding layer 16 are sequentially formed on the LED film 11 by electron beam evaporat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com