DMF (dimethyl fumarate) enteric-coated micropellet and preparation method thereof

A technology of dimethyl fumarate enteric and dimethyl fumarate, which is applied in the field of dimethyl fumarate enteric-coated pellets and its preparation, can solve the problem of not being able to obtain the release advantages of multi-unit enteric-coated preparations To reduce gastrointestinal irritation, easy sublimation loss of dimethyl fumarate and other problems, to achieve the effect of reducing gastrointestinal side effects, complete drug release, and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

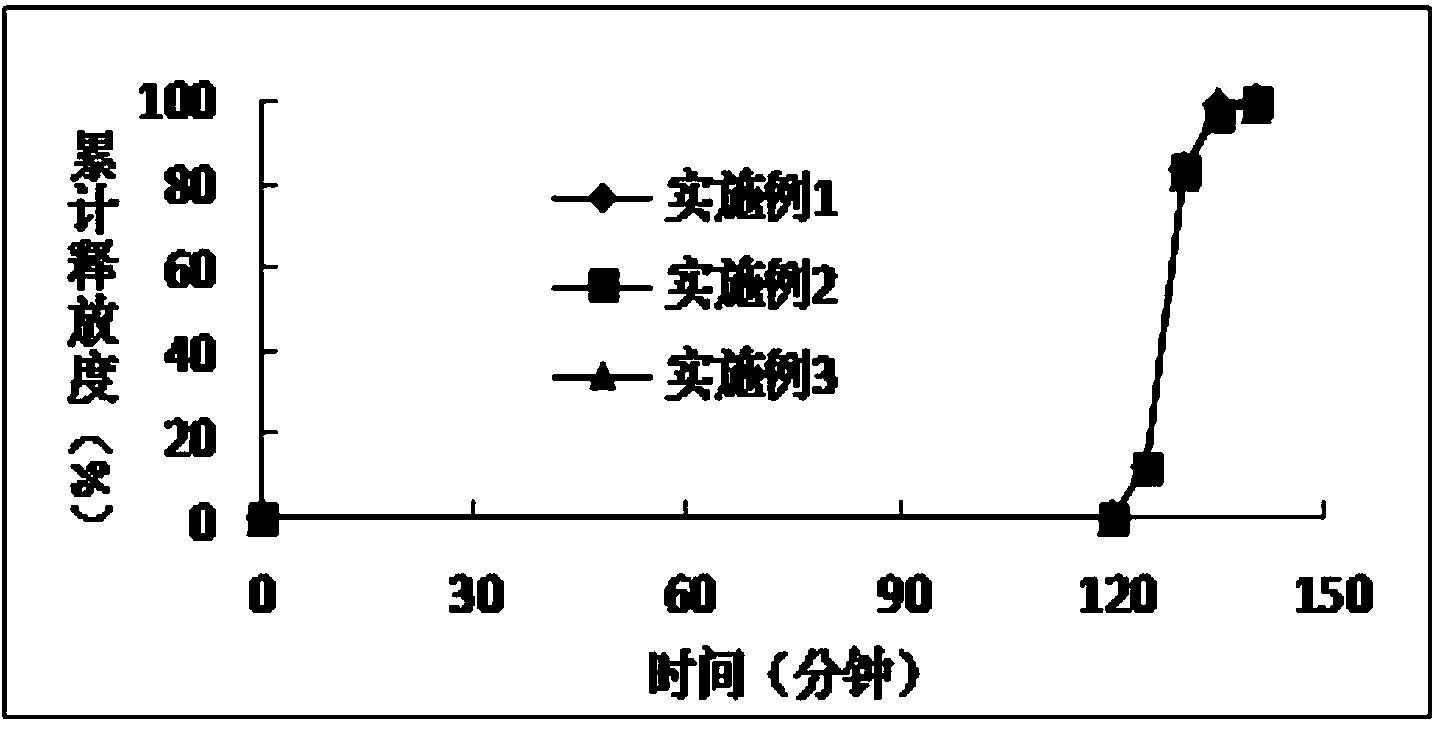

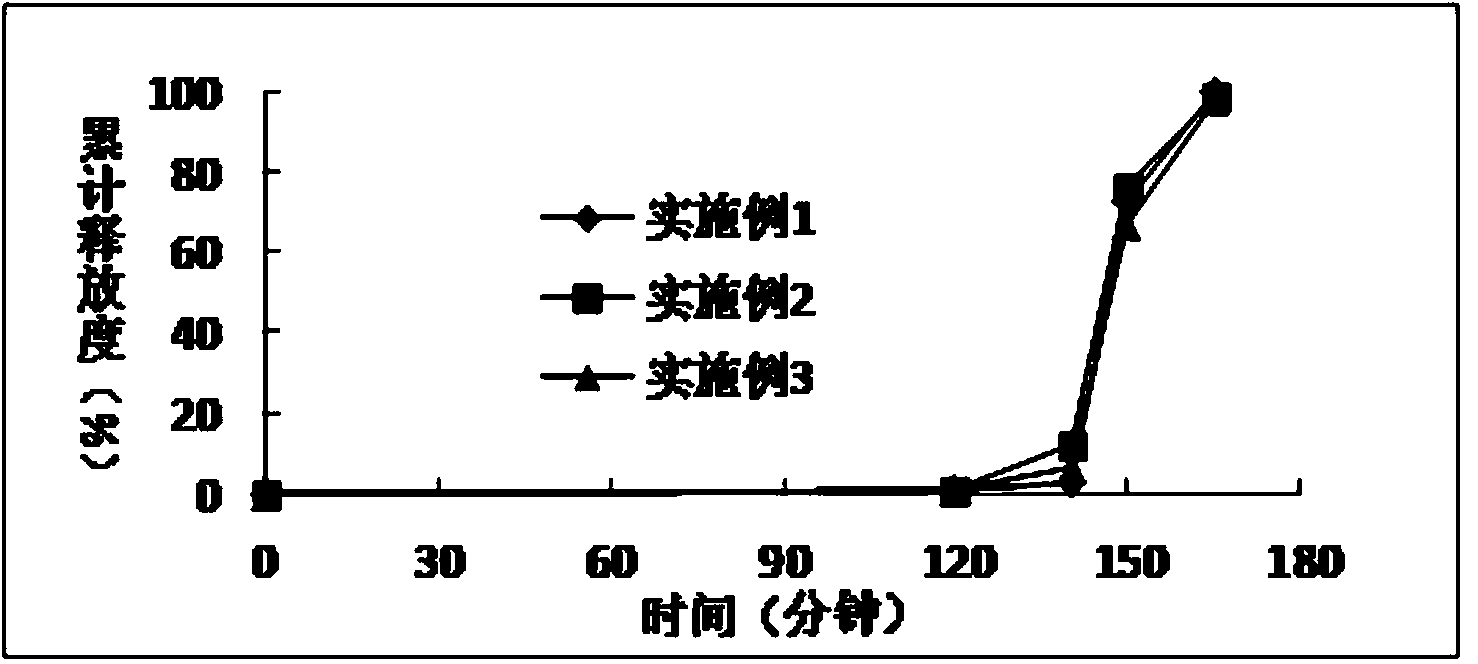

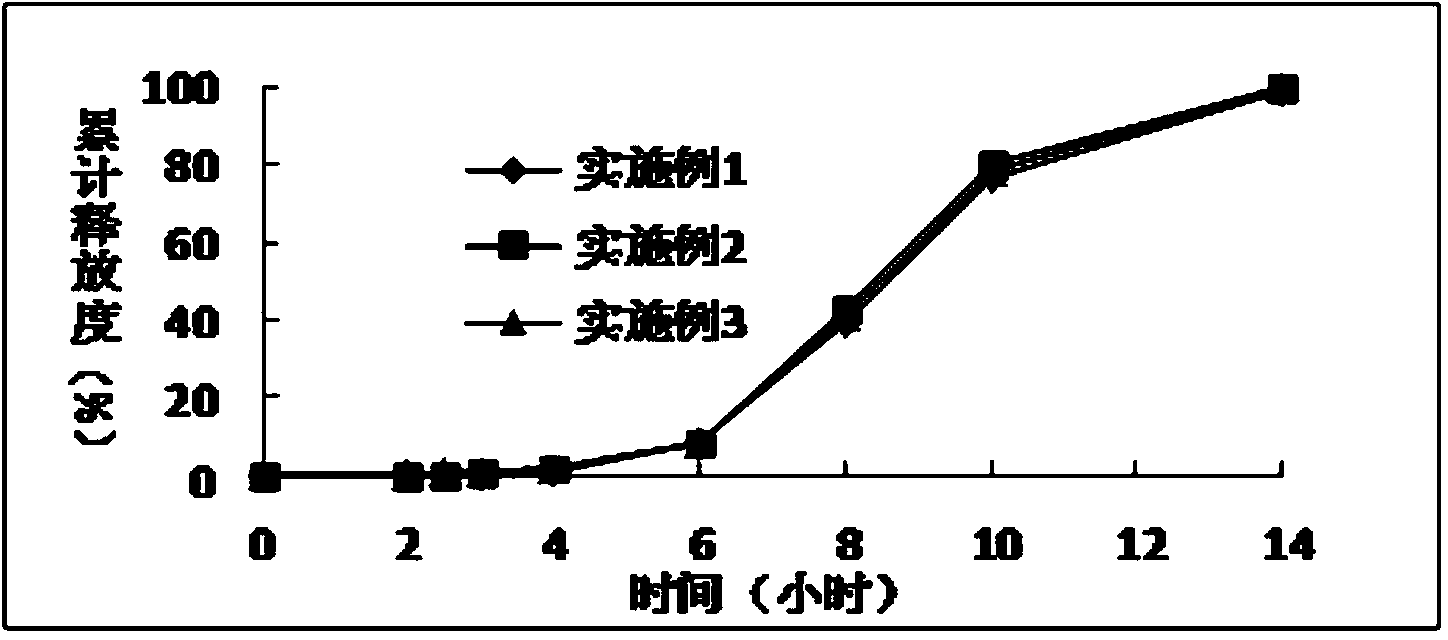

Embodiment 1

[0041] Composition of dimethyl fumarate enteric-coated pellets:

[0042] Ball core composition:

[0043] Raw material name 1000 dosage (g)

[0044] Dimethyl fumarate 120

[0045] Microcrystalline Cellulose 150

[0046] Sodium carboxymethyl starch 20

[0047] Hydroxypropyl Cellulose 13

[0048] 95% ethanol 103

[0049] Purified water 116

[0050] Composition of the inner enteric coating layer:

[0051] Raw material name dosage (g)

[0052] Udage L12.5 12.5

[0053] Triethyl citrate 1

[0055] 95% ethanol 170

[0056] Composition of the outer enteric coating layer:

[0057] Raw material name dosage (g)

[0058] Eudragit L30D-55 water dispersion 150

[0059] Triethyl citrate 5

[0060] Talc 12

[0061] Purified water...

Embodiment 2

[0074] Composition of dimethyl fumarate enteric-coated pellets:

[0075] Ball core composition:

[0076] Raw material name 1000 dosage (g)

[0077] Dimethyl fumarate 120

[0078] Microcrystalline Cellulose 100

[0079] Lactose 50

[0080] Croscarmellose Sodium 25

[0081] Hypromellose 14

[0082] 95% ethanol 103

[0083] Purified water 116

[0084] Composition of the inner enteric coating layer:

[0085] Raw material name dosage (g)

[0086] Udrake L100 15

[0087] Triethyl citrate 2

[0088] Talc 4

[0089] 95% ethanol 200

[0090] Composition of the outer enteric coating layer:

[0091] Raw material name dosage (g)

[0092] Cellulose acetate phthalate 50

[0093] Triethyl citrate 5

[0094] Talc powder 10

[0095] Pu...

Embodiment 3

[0107] Composition of dimethyl fumarate enteric-coated pellets:

[0108] Ball core composition:

[0109] Raw material name 1000 dosage (g)

[0110] Dimethyl fumarate 120

[0111] Microcrystalline Cellulose 150

[0112] Croscarmellose Sodium 20

[0113] Povidone K30 14

[0114] 95% ethanol 103

[0115] Purified water 116

[0116] Composition of the inner enteric coating layer:

[0117] Raw material name dosage (g)

[0118] Udrake L100 15

[0119] Triethyl citrate 5

[0120] Talc 5

[0121] 95% ethanol 200

[0122] Composition of the outer enteric coating layer:

[0123] Raw material name dosage (g)

[0124] Eudragit L30D-55 aqueous dispersion 170

[0125] Triethyl citrate 5

[0126] Talc 15

[0127] Purified water 220 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com