Industrial preparation method for preparing sodium hydrogen carbonate for smoke purification from waste alkali

A technology for purification of sodium bicarbonate and flue gas, applied in the directions of alkali metal carbonate, chemical instruments and methods, separation methods, etc., can solve the problems of increasing the industrial scale, staying in the crude product stage, increasing the cost of the preparation process, etc. Solve environmental pollution, solve discharge and treatment, and achieve significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

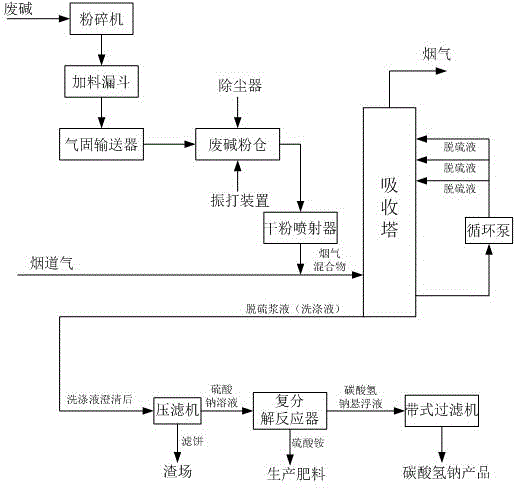

Method used

Image

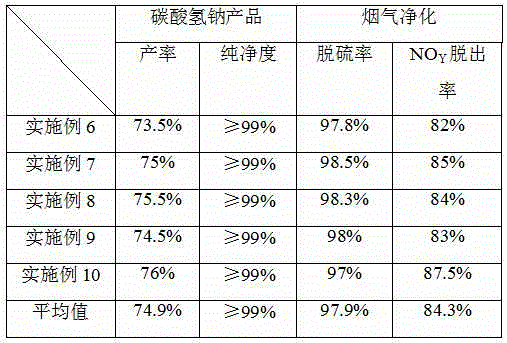

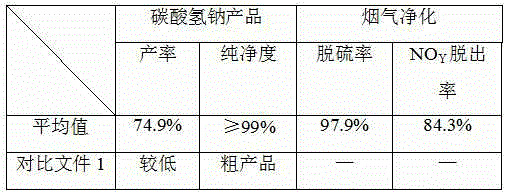

Examples

Embodiment 1

[0069] This example uses the flue gas mixture formed by mixing spent caustic soda and flue gas, and the Na obtained after circular washing and clarification 2 SO 4 Solution to prepare the process of sodium bicarbonate product, wherein, spent caustic soda is dry solid, and by weight percentage, spent caustic contains 50% Na 2 CO 3 , 35% Na 2 SO 4 And 15% of other impurities, such as: NaCl, free carbon, insoluble impurities, etc.

Embodiment 2

[0071] The difference between this embodiment and Example 1 is: the spent caustic soda used is sodium carbonate spent caustic, and by weight percentage, this sodium carbonate spent caustic contains 85% Na 2 CO 3 , 12% Na 2 SO 4 And 3% of other impurities, such as: NaCl, free carbon, insoluble impurities, etc.

Embodiment 3

[0073] The difference between this embodiment and Example 1 is that the spent caustic soda used is caprolactam incinerated spent caustic, and by weight percentage, the caprolactam incinerated spent caustic contains 65% Na 2 CO 3 , 30% Na 2 SO 4 And 5% NaCl. Of course, in actual use, its composition may inevitably include other impurities such as free carbon and insoluble matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com