Method for preparing magnetic nano-composites and removing phenols pollutants in water

A magnetic nano-composite technology, which is applied in chemical instruments and methods, alkali metal compounds, water/sewage treatment, etc., can solve the problems of imperfect synthesis methods, low adsorption efficiency, and low reuse rate, and achieve excellent adsorption ability, simple preparation method, and the effect of saving economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

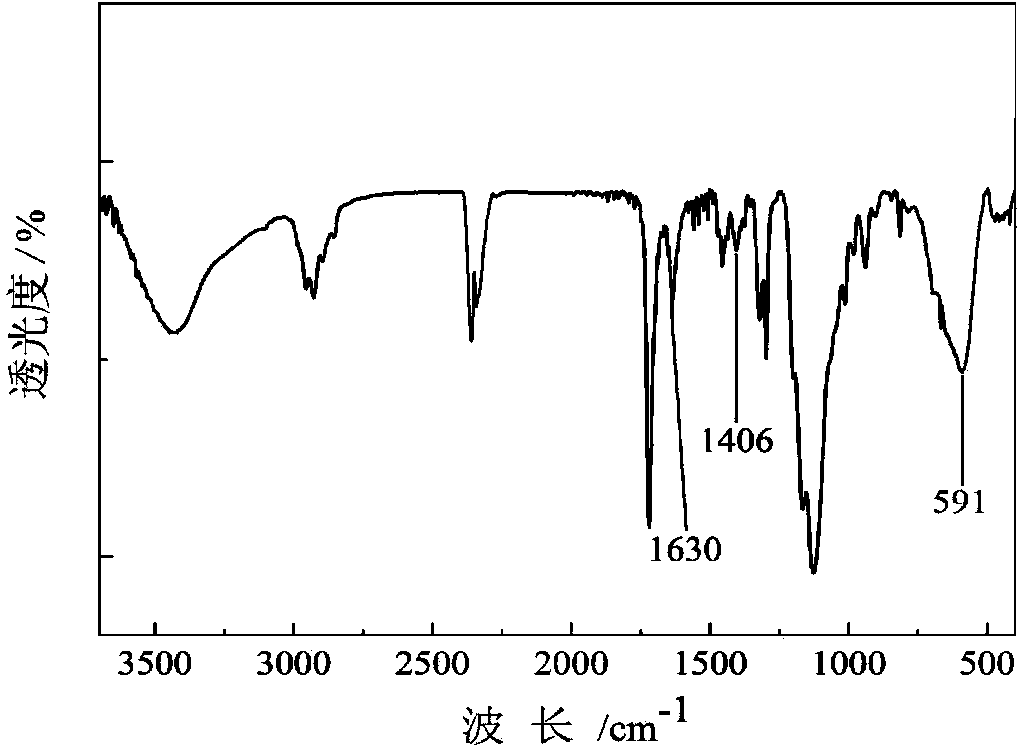

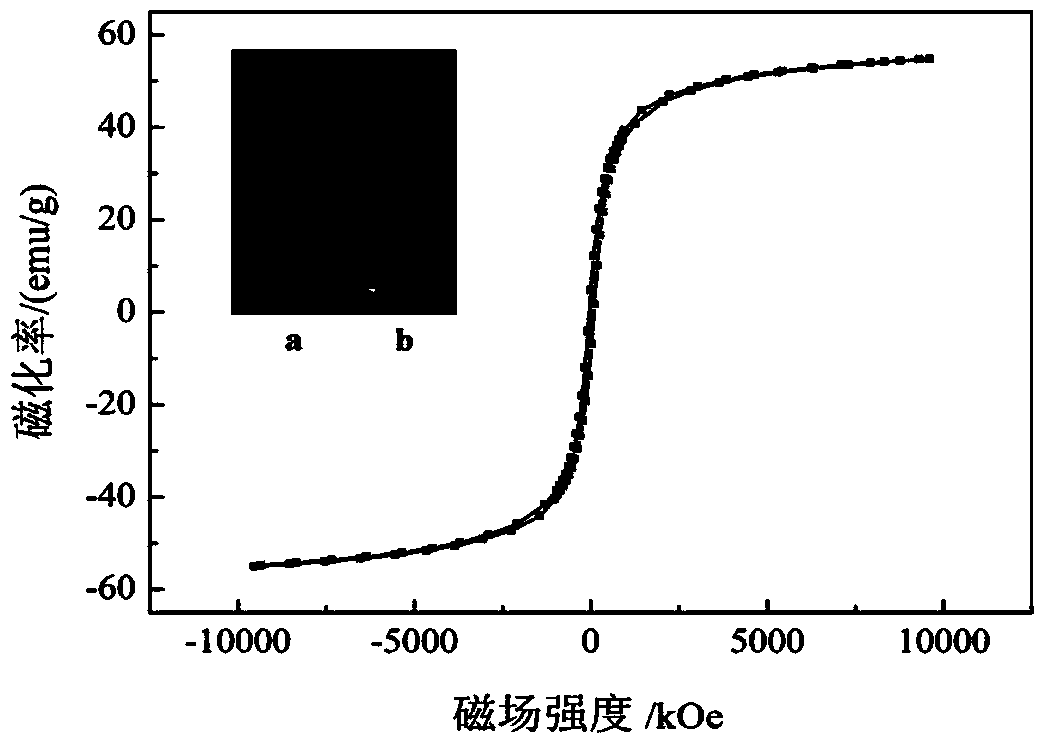

[0022] Example 1: Carboxymethyl-β-cyclodextrin polymer functionalized Fe 3 o 4 Preparation of magnetic nanocomposites (CMCDP-MNPs)

[0023] (1) Preparation of carboxymethyl-β-cyclodextrin polymer (CMCDP): 4.5g β-cyclodextrin and 8.73g sodium chloroacetate were dissolved in 20mL, 2.5mol / L sodium hydroxide solution, 80 After heating and stirring at ℃ for 3 hours, cool to room temperature, add 5 mL of epichlorohydrin to the mixed solution, stir vigorously for 8 hours, then add 5 mL of epichlorohydrin, and continue stirring for 24 hours to stop the reaction. Add an appropriate amount of absolute ethanol to the mixture to produce a white precipitate, continue to add absolute ethanol until the white precipitate no longer occurs, filter, wash the precipitate with absolute ethanol several times, and finally dry the white precipitate at 50°C in vacuum to obtain CMCDP.

[0024] (2) Preparation of CMCDP-MNPs: 2.35g FeCl 3 ·6H 2 O, 0.89FeCl 2 4H 2 0, 2.0g of the CMCDP prepared in s...

Embodiment 2

[0026] Example 2: Adsorption of bisphenol A by CMCDP-MNPs

[0027] Add 10 mg of CMCDP-MNPs to 50 mL, 5-30 mg / L bisphenol A aqueous solution, adjust the pH of the solution to 5, shake at room temperature for 4 hours, and measure the fluorescence of the supernatant on a Cary Eclipse fluorescence spectrophotometer after magnetic separation Intensity (λex=274nm, λem=307nm), and calculate the adsorption amount Q of CMCDP-MNPs to bisphenol A by formula 1 e (mg / g):

[0028] Q e =(C 0 -C e )V / m (1)

[0029] where C 0 is the initial concentration of bisphenol A (mg / L), C e is the residual concentration of bisphenol A (mg / L), V is the solution volume (L), m is the mass of CMCDP-MNPs (g)

[0030] The experiment was repeated three times, and the average value was calculated. The result is as Figure 4 shown. The maximum adsorption capacity of CMCDP-MNPs to bisphenol A was 62mg / g.

Embodiment 3

[0031] Example 3: Adsorption of Resorcinol by CMCDP-MNPs

[0032]Add 10 mg of CMCDP-MNPs to 50 mL, 5-30 mg / L resorcinol aqueous solution, adjust the pH of the solution to 5, shake at room temperature for 4 h, and measure the concentration of the supernatant on a Cary Eclipse fluorescence spectrophotometer after magnetic separation. Fluorescence intensity (λex=272nm, λem=305nm), and calculate the adsorption amount Q of CMCDP-MNPs p-resorcinol by formula 2 e (mg / g):

[0033] Q e =(C 0 -C e )V / m (2)

[0034] where C 0 is the initial concentration of resorcinol (mg / L), C e is the residual concentration of resorcinol (mg / L), V is the solution volume (L), m is the mass of CMCDP-MNPs (g)

[0035] The experiment was repeated three times, and the average value was calculated. The result is as Figure 5 shown. The maximum adsorption capacity of CMCDP-MNPs to resorcinol was 84mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com