Anti-aging sealant and preparation method thereof

A sealant, aging-resistant technology, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of curing speed, stability, aging resistance, adhesive strength, etc. that cannot meet the growing needs, and achieve excellent comprehensive performance, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

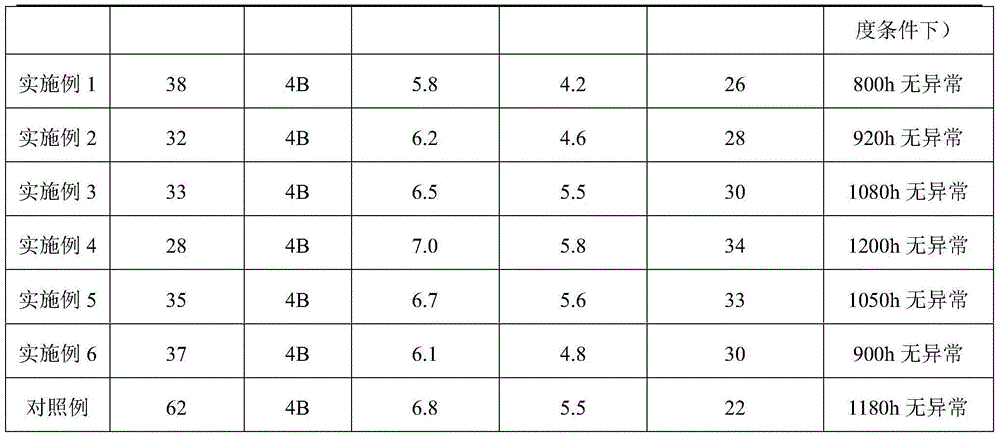

Examples

Embodiment 1

[0028] An anti-aging sealant, comprising by weight components: 20 parts of coumarone resin, 5 parts of polysulfide rubber, 5 parts of nitrile rubber, 8 parts of tert-butylphenol formaldehyde resin, 3 parts of nano silicon dioxide, chlorosulfur 2 parts of polyethylene, 2 parts of butyl acrylate, 1 part of aluminum powder, 3 parts of sodium metasilicate, 2 parts of phosphoric acid ester, 1 part of triethanolamine, 1 part of boron nitride, 0.5 parts of paraffin, 2,4-dihydroxy 1 part of benzophenone, 0.8 part of butyl p-hydroxybenzoate.

[0029] Among the above components, the particle size of the aluminum powder is 300 μm, and the particle size of the boron nitride is 200 μm.

[0030] The preparation method of the described aging-resistant sealant comprises the following preparation steps:

[0031] (1) take each component according to parts by weight;

[0032] (2) Add each component into the reaction kettle, mix and stir evenly, then heat to 120°C under the condition of vacuum ...

Embodiment 2

[0034] An aging-resistant sealant, comprising by weight components: 26 parts of coumarone resin, 6 parts of polysulfide rubber, 7 parts of nitrile rubber, 9 parts of tert-butylphenol formaldehyde resin, 4 parts of nano silicon dioxide, chlorosulfur 3 parts of polyethylene, 3 parts of butyl acrylate, 3 parts of aluminum powder, 4 parts of sodium metasilicate, 4 parts of phosphoric acid ester, 2 parts of triethanolamine, 2 parts of boron nitride, 0.8 parts of paraffin, 2,4-dihydroxy 2 parts of benzophenone, 2 parts of butyl p-hydroxybenzoate.

[0035] Among the above components, the particle size of the aluminum powder is 250 μm, and the particle size of the boron nitride is 180 μm.

[0036] The preparation method of the described aging-resistant sealant comprises the following preparation steps:

[0037] (1) take each component according to parts by weight;

[0038] (2) Add each component into the reaction kettle, mix and stir evenly, then heat to 125°C under the condition of...

Embodiment 3

[0040] An aging-resistant sealant, comprising by weight components: 27 parts of coumarone resin, 6 parts of polysulfide rubber, 7 parts of nitrile rubber, 10 parts of tert-butylphenol formaldehyde resin, 5 parts of nano silicon dioxide, chlorosulfur 3 parts of polyethylene, 4 parts of butyl acrylate, 4 parts of aluminum powder, 5 parts of sodium metasilicate, 6 parts of phosphoric acid ester, 2 parts of triethanolamine, 2 parts of boron nitride, 1 part of paraffin, 2,4-dihydroxy 2 parts of benzophenone, 2.2 parts of butyl p-hydroxybenzoate.

[0041] Among the above components, the particle size of the aluminum powder is 250 μm, and the particle size of the boron nitride is 150 μm.

[0042] The preparation method of the described aging-resistant sealant comprises the following preparation steps:

[0043] (1) take each component according to parts by weight;

[0044] (2) Add each component into the reaction kettle, mix and stir evenly, then heat to 130°C under the condition of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com