Bioadhesive type hollow microsphere and preparation method thereof

A technology of bioadhesion and microspheres, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems affecting the gas production and floating performance of preparations, and affect the residence time. Achieve the effect of improving bioavailability, improving bioadhesion, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

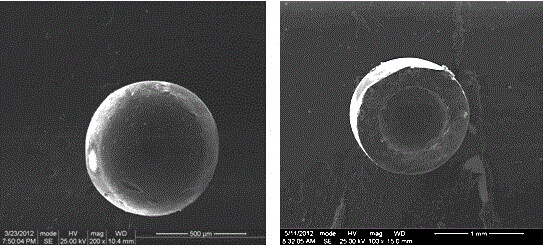

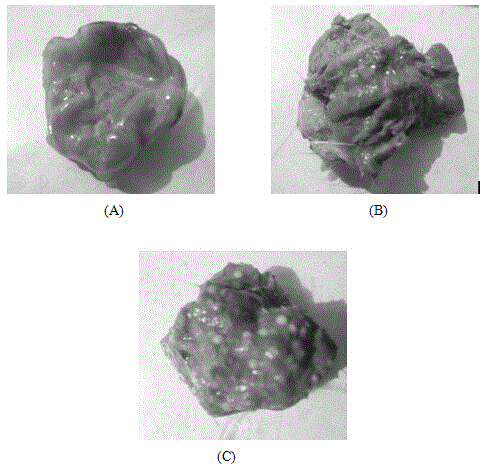

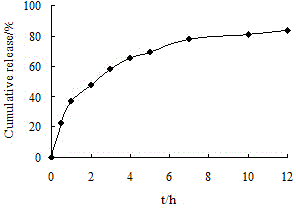

[0040] Example 1: Dipyridamole bioadhesive hollow microspheres

[0041] 1. Basic experimental conditions:

[0042] The ratio of dipyridamole to ethyl cellulose is 1:5; 1.2% (w / v) of carbomer is used as the adhesive material; the ratio of anhydrous ethanol to anhydrous ether is 4:1 (v / v); liquid paraffin is Dispersion medium; the ratio of the dispersed phase to the continuous phase is 1:10 (v / v); 1.0% (w / v) of Span 80 is an emulsifier; 0.02% (w / v) of magnesium stearate is a dispersant; Stirring rate is 300r·min -1 ; Emulsification temperature is 10℃, curing temperature is 30℃; drying condition is 30℃ oven drying for 24h.

[0043] 2. Experimental operation:

[0044] Disperse carbomer, ethyl cellulose and dipyridamole in a mixed organic solvent, stir in a water bath at 10°C to dissolve the dispersed phase; add the dispersed phase slowly under mechanical stirring in a water bath at 10°C In the liquid paraffin containing emulsifier and dispersant, emulsify and volatilize after emulsifica...

Embodiment 2

[0055] Example 2: Selection of Carbomer Concentration

[0056] The concentration of carbomer was changed to prepare microspheres, the appearance was observed, and the floating rate and adhesion rate were measured. The results are shown in Table 2.

[0057] Table 2 The effect of carbomer 934 concentration on the properties of microspheres

[0058]

Embodiment 3

[0059] Example 3: Selection of organic solvent ratio

[0060] The concentration of organic reagents was changed to prepare microspheres, the appearance was observed, and the floating rate and adhesion rate were measured. The results are shown in Table 3.

[0061] Table 3 Effect of the ratio of ethanol to ether on the properties of microspheres

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com