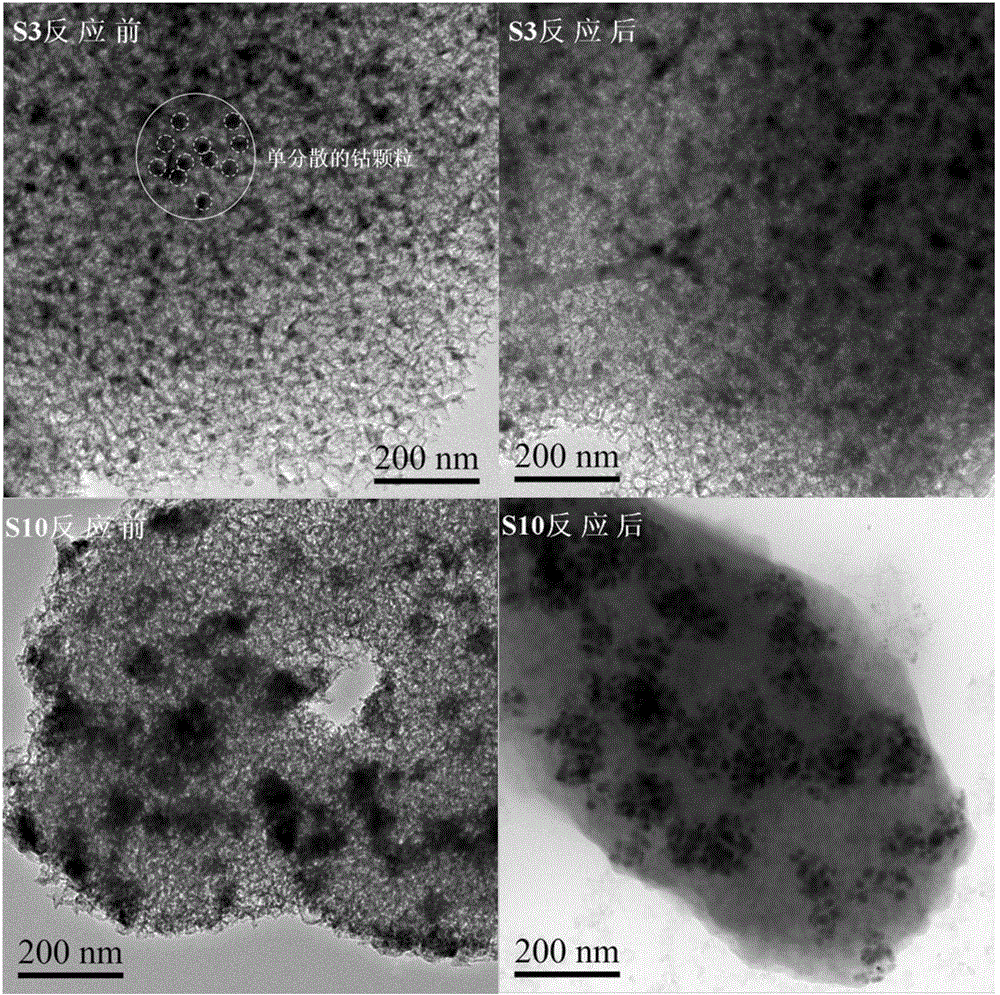

Preparation method of cobalt-based Fischer-Tropsch synthesis catalyst with controllable mono-dispersed particles

A cobalt-based Fischer-Tropsch synthesis technology, which is applied in the field of Fischer-Tropsch synthesis catalyst preparation, can solve the problems of difficult sintering, difficult control of cobalt crystal grains, and poor dispersion, and achieves low carbon deposition, low deactivation, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

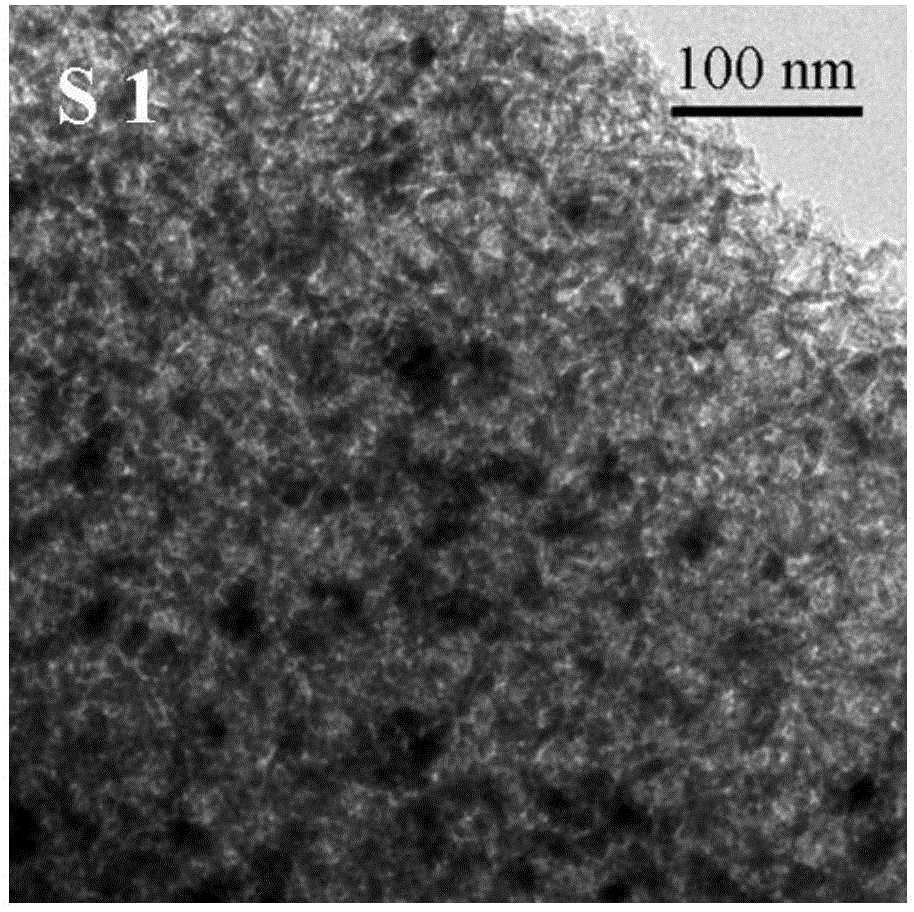

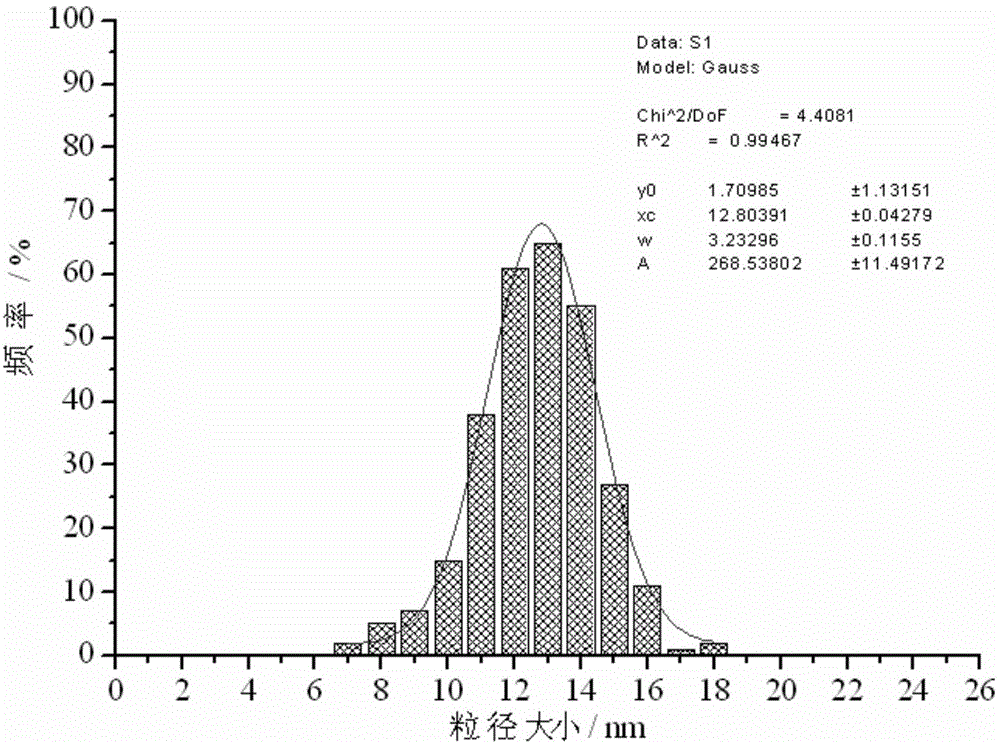

Embodiment 1

[0045] A kind of preparation method of 15Co / MCF-1 catalyst, its steps are as follows:

[0046] Get 2.0g silica mesoporous foam (specific surface area 654.6m 2 / g, small pore diameter 9.2nm, large pore diameter 45.1nm) baked in an oven at 100°C for 24h;

[0047] Mix 0.13g of absolute ethanol with 3.6g of distilled water, then add 0.04g of citric acid to obtain a mixed solution, then weigh 1.74g of cobalt nitrate and dissolve it in the above mixed solution to obtain a mixed solution containing cobalt sources;

[0048] Then, while rotating on the rotary evaporator, use a constant flow pump to evenly and slowly drop the mixed solution containing the cobalt source into the silicon oxide mesoporous foam. The rotating speed of the rotary evaporator is 80r / min. The mixed solution of the cobalt source was added dropwise in 70 minutes, therefore, the flow rate of the constant flow pump was 1.0ml / min. During the dripping process, when the carrier forms a large mass, stop the rotation a...

Embodiment 2

[0053] A kind of preparation method of 15Co / MCF-2 catalyst, its steps are as follows:

[0054] Get 2.0g silica mesoporous foam (specific surface area 654.6m 2 / g, small pore diameter 9.2nm, large pore diameter 45.1nm) baked in an oven at 100°C for 24h;

[0055] Mix 0.13g of absolute ethanol with 3.6g of distilled water, then add 0.8g of citric acid to obtain a mixed solution, then weigh 1.74g of cobalt nitrate and dissolve it in the above mixed solution to obtain a mixed solution containing cobalt sources;

[0056] Then, while rotating on the rotary evaporator, use a constant flow pump to evenly and slowly drop the mixed solution containing the cobalt source into the silicon oxide mesoporous foam. The rotating speed of the rotary evaporator is 80r / min. The mixed solution of the cobalt source was added dropwise in 70 minutes, therefore, the flow rate of the constant flow pump was 1.0ml / min. During the dripping process, when the carrier forms a large mass, stop the rotation an...

Embodiment 3

[0061] A kind of preparation method of 15Co / MCF-3 catalyst, its step is as follows:

[0062] Get 2.0g silica mesoporous foam (specific surface area 654.6m 2 / g, small pore diameter 9.2nm, large pore diameter 45.1nm) baked in an oven at 100°C for 24h;

[0063] Mix 0.13 g of absolute ethanol with 3.6 g of distilled water, then add 0.4 g of citric acid to obtain a mixed solution, then weigh 1.74 g of cobalt nitrate and dissolve in the above mixed solution to obtain a mixed solution containing cobalt sources;

[0064] Then, while rotating on the rotary evaporator, use a constant flow pump to evenly and slowly drop the mixed solution containing the cobalt source into the silicon oxide mesoporous foam. The rotating speed of the rotary evaporator is 80r / min. The mixed solution of the cobalt source was added dropwise in 70 minutes, therefore, the flow rate of the constant flow pump was 1.0ml / min. During the dripping process, when the carrier forms a large mass, stop the rotation and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com