Pd@PtNi/C metal nano-catalyst, and preparation method and use thereof

A metal nano-catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high reaction cost, unfavorable large-scale preparation, etc. Simple procedure, mild conditions and short operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Prepare a solution of octahedral-shaped Pd nanocrystals with an average size of 26 nm and a concentration of 0.3 mg / mL:

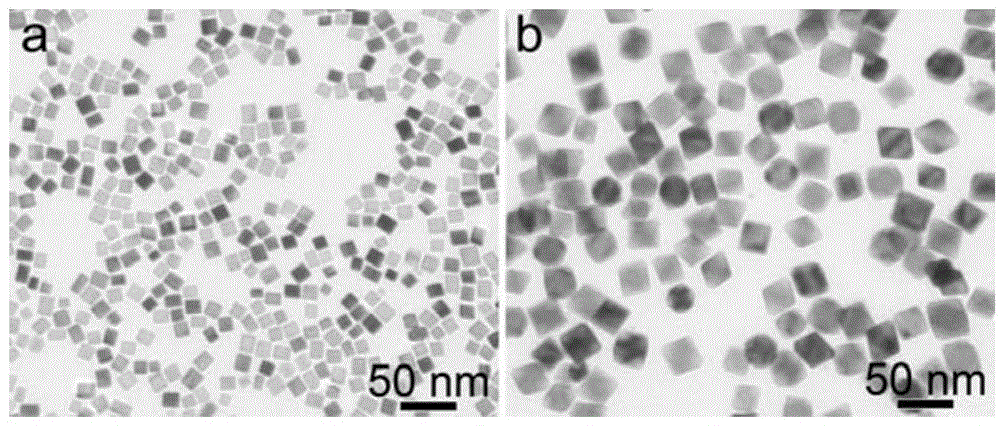

[0026]Step 1: Add 105mg of PVP, 60mg of ascorbic acid, 300mg of potassium bromide and 8mL of deionized water to a 20mL glass reaction bottle in turn at room temperature, and magnetically stir the mixed solution at 80°C for 10 minutes. Subsequently, 3 ml of sodium tetrachloropalladate aqueous solution containing 57 mg of sodium tetrachloropalladate was added, and after heating at 80° C. for 3 hours, the following figure 1 a, Solution of cubic Pd nanocrystals with an average size of 11 nm. The solution of cubic Pd nanocrystals was centrifuged and washed with deionized water to obtain 11 mg of cubic Pd nanocrystals, which were redispersed in 11 mL of deionized water to obtain a solution of cubic Pd nanocrystals with a concentration of 1 mg / mL;

[0027] The second step: at room temperature, add to the glass reaction bottle of 20mL successively: 105mg of...

Embodiment 2

[0029] Preparation of PdPtNi nanocrystals with an octahedral core-shell structure with an average size of 28 nm:

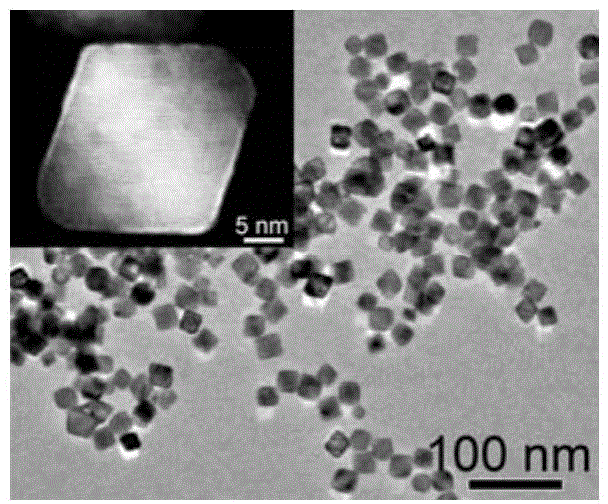

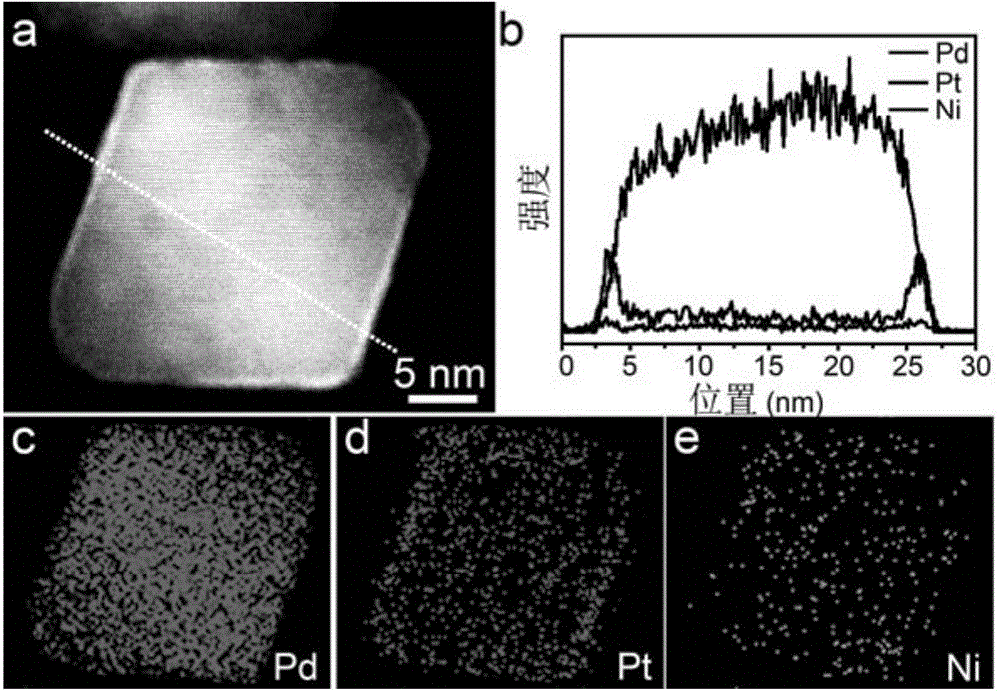

[0030] At room temperature, add 105mg of PVP, 328mg of citric acid monohydrate and 6mL of deionized water to a 20mL glass reaction bottle in turn, dissolve them, and then add octahedral Pd nanocrystals with a concentration of 0.3mg / mL 1 mL of the solution and 0.5 mL of hydrazine hydrate with a mass fraction of 85%, and the mixed solution was magnetically stirred at 65° C. for 5 minutes. Then, slowly inject 1.5 mL of 19.8 mg K into the glass reaction vial 2 PtCl 4 and 1.1mg NiCl 2 ·6H 2 Mixed aqueous solution of O, after continuing magnetic stirring at 65°C for 15 minutes, the product was obtained, as figure 2 It can be seen from the figure that the obtained product has uniform size and good dispersion. The side length of a single particle is 28 nm. The distribution of elements in its entire area can be given by image 3 It is known that Pt and Ni elements ...

Embodiment 3

[0032] Preparation of PdPtNi / C metal nanocatalysts for cathode oxygen reduction reaction in proton exchange membrane fuel cells:

[0033] The concentration of platinum in the PdPtNi nanocrystal solution with an octahedral core-shell structure prepared in Example 2 was measured to be 7.5 μg / mL. In order to make the mass fraction of platinum in the final product 20%, 0.78 mL of 0.34 mg was added thereto. The ethanol solution of the carbon black of / mL, after ultrasonic 3 hours and stir 12 hours, centrifuge under 45000rpm, and continue to wash 5 times with deionized water under the same rotating speed, dry, the obtained product is as follows Figure 4 Shown in, namely PdPtNi / C metal nanocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com