Laboratory effluent treatment device

A laboratory waste liquid and treatment device technology, which is applied in the field of pollution prevention and control devices, can solve the problems of difficult to effectively treat combustion tail gas and high processing costs, and achieve the effects of increasing waste liquid types, small footprint, and low engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

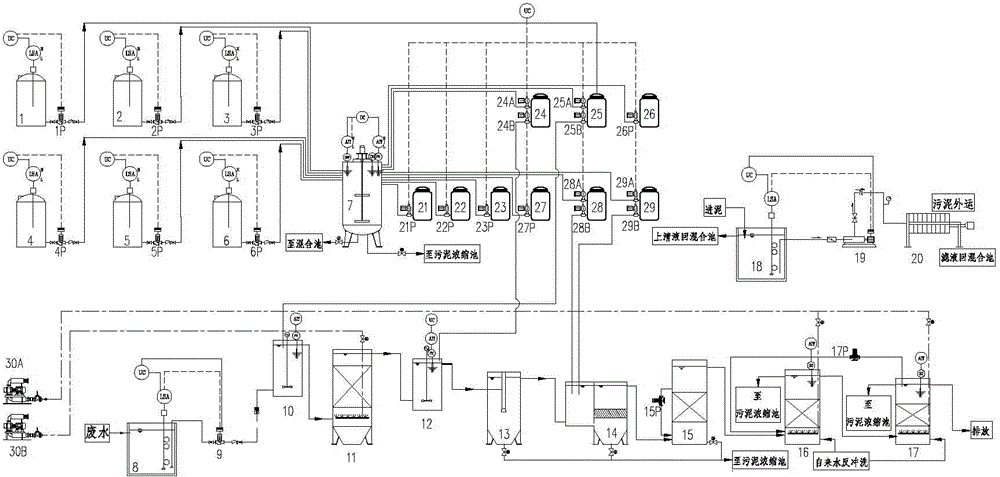

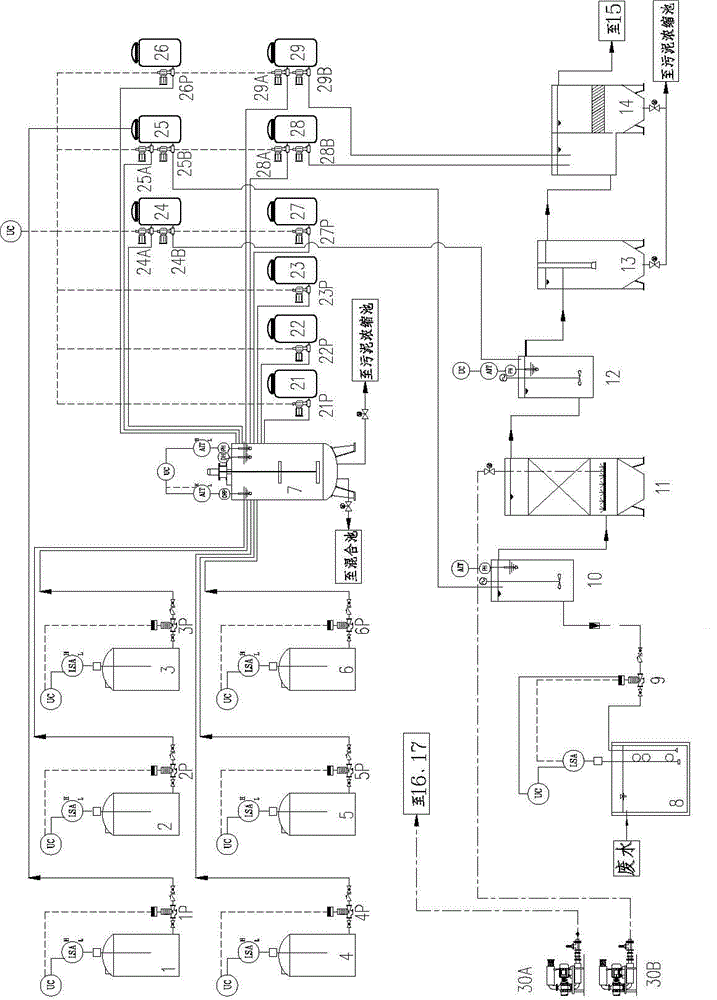

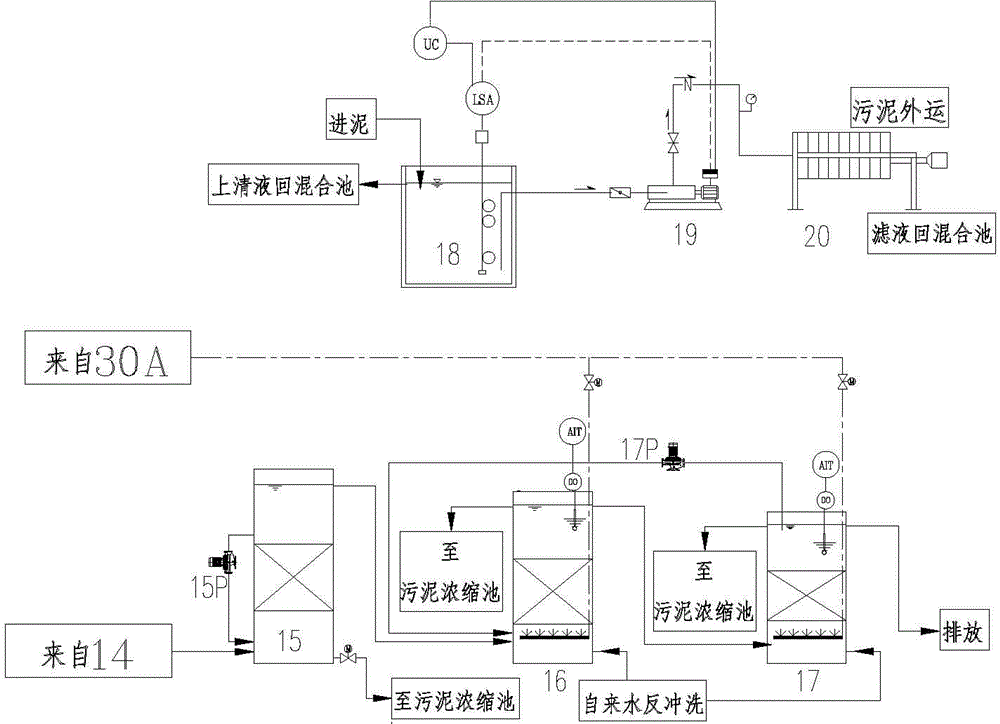

[0019] Such as Figure 1-3 As shown, the device includes a waste liquid classification storage tank, a redox reactor 7, a mixing tank 8, a pH adjustment tank, a micro-electrolysis reactor 11, a hydrolytic acidification reactor 15, a DN biological aerated filter 16, and a C / N aeration tank. Gas biofilter 17, inclined plate sedimentation tank, sludge concentration tank 18, multiple medicine storage boxes and chamber filter press 20; there are multiple waste liquid classification storage tanks, which are respectively waste acid liquid storage tank 1, organic waste Liquid storage tank 2, mercury-based waste liquid storage tank 3, hexavalent chromium waste liquid storage tank 4, heavy metal waste liquid storage tank 5 and cyanide-containing waste liquid storage tank 6; the medicine storage box includes a calcium hydroxide medicine storage box 22 , sodium hydroxide storage box 24, polyacrylamide storage box 29, polyaluminum chloride storage box 28, ferrous sulfate storage box 27, hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com