Modified alumina composite material, copper clad substrate and preparation method thereof

A technology for composite materials and copper-clad substrates, applied in chemical instruments and methods, circuit substrate materials, synthetic resin layered products, etc. Problems such as low force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

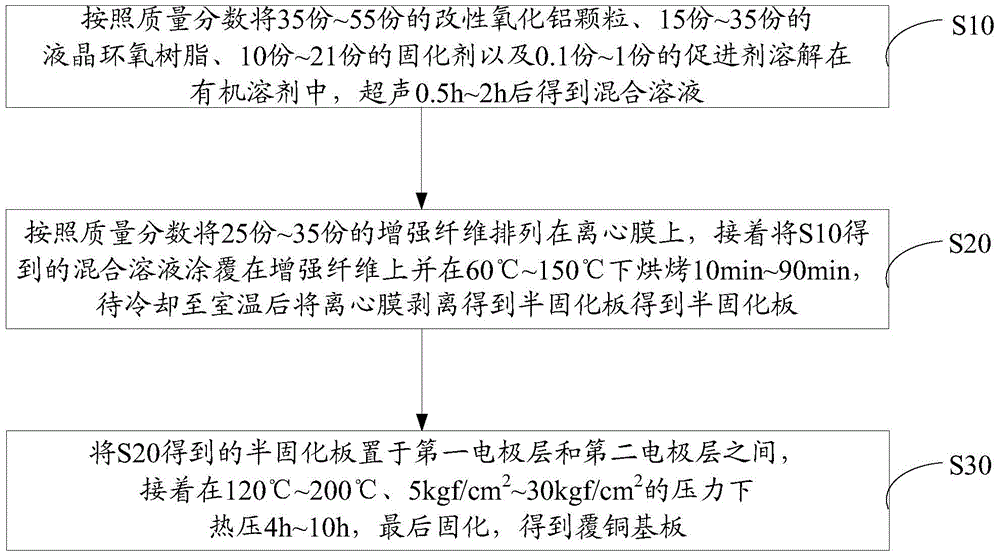

[0059] Such as figure 1 The preparation method of the above-mentioned copper-clad substrate shown includes the following steps:

[0060] S10. Dissolve 35-55 parts of modified alumina particles, 15-35 parts of liquid crystal epoxy resin, 10-21 parts of curing agent and 0.1-1 part of accelerator in an organic solvent according to the mass fraction , the mixed solution was obtained after ultrasonication for 0.5h-2h.

[0061] The organic solvent can be 2-butanone or acetone.

[0062] The modified alumina particles are obtained by modifying the alumina particles with a silane coupling agent. The particle size of the modified alumina particles may be 100nm-1000nm.

[0063] In a preferred embodiment, the particle size of the modified alumina particles is 700nm.

[0064] The silane coupling agent is γ-aminopropyltriethoxysilane, γ-(2,3-glycidoxy)propyltrimethoxysilane or γ-methacryloxypropyltrimethoxysilane.

[0065] The process of modifying alumina particles with silane coupling...

Embodiment 1

[0086] (1) Preparation of γ-aminopropyltriethoxysilane-modified alumina.

[0087] First, dry the alumina particles at 110°C for 4 hours. After cooling to room temperature, weigh 15.0 g of alumina particles with a particle size of 700 nm and 50 mL of xylene into a three-necked flask for ultrasonic dispersion for 10 minutes, then put them in an oil bath, and stir them magnetically. solution and warmed to 90°C. Add 1.0 g of the surface modifier γ-aminopropyltriethoxysilane dropwise with a dropper, raise the temperature to 115° C. after the dropwise addition, keep magnetic stirring, and react for 6 hours.

[0088] Cool the mixed solution, pour it into a suction filter funnel while it is hot, wash the sample obtained by suction filtration with absolute ethanol several times, put it in a vacuum drying oven at 110°C for 12 hours, and obtain γ-aminopropyltriethoxysilane surface-modified of alumina.

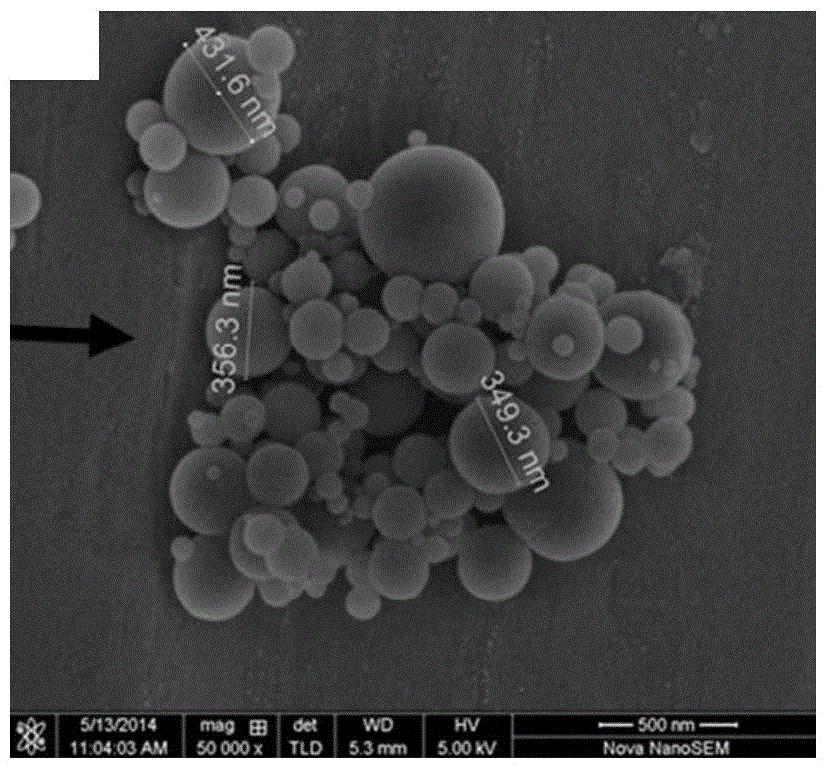

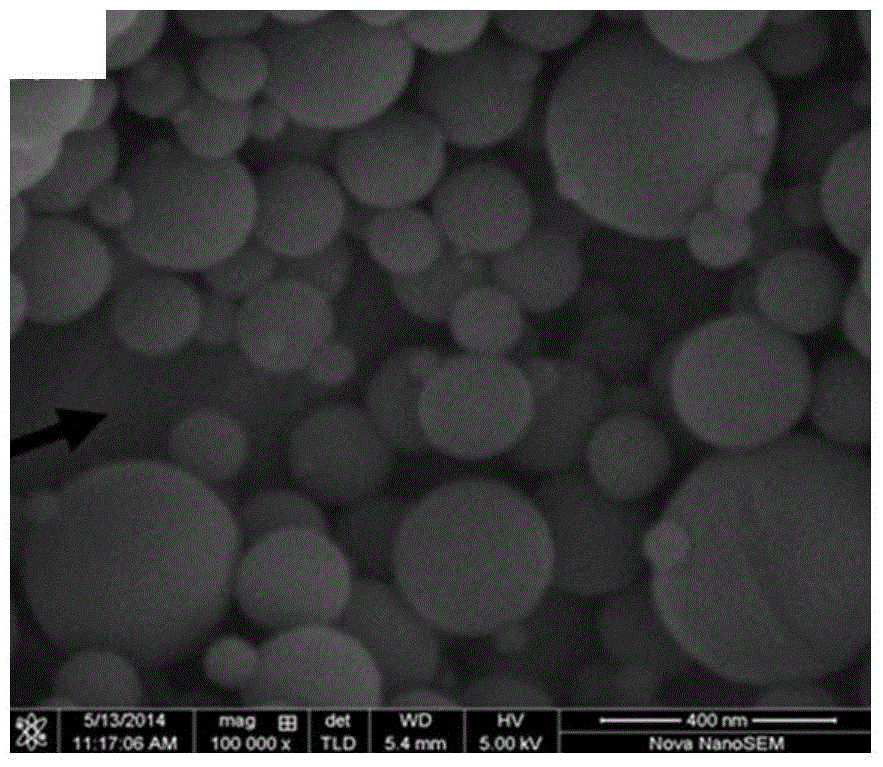

[0089] figure 2 and image 3 These are the SEM pictures of the alumina particles...

Embodiment 2

[0105] The preparation method is basically the same as that of Example 1, except that the curing agent used in step (2) is 4,4'-dihydroxybiphenyl, stirred and mixed evenly at 130°C, and reacted at 130°C for 30 minutes to obtain amber viscous transparent epoxy resin compound.

[0106] The prepared copper-clad substrate includes a first electrode layer, a dielectric layer and a second electrode layer stacked in sequence, wherein both the first electrode layer and the second electrode layer are copper foil sheets with a thickness of 40 microns, and the dielectric layer consists of two prepregs composition, with a thickness of 500 microns.

[0107] After testing, it was found that the radial thermal conductivity of the substrate material was 0.876W / m·K, the axial thermal conductivity was 1.358W / m·K, and the glass transition temperature was 130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com