High-energy carbon alcohol clean fuel slurry and preparation method thereof

A technology of clean fuel and carbon-alcohol slurry, which is applied in the field of clean coal to achieve the effect of increasing the burning rate, reducing the surface tension and improving the cleanliness of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

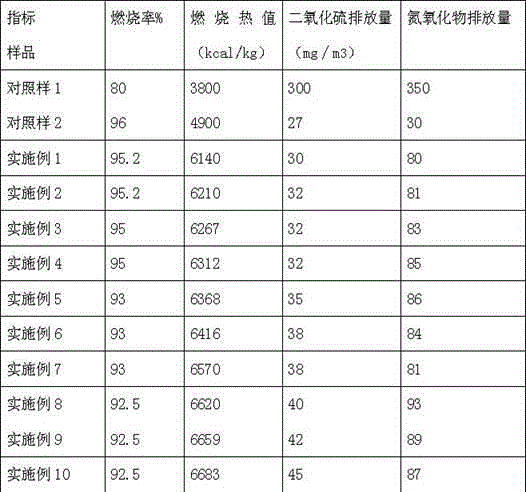

Examples

Embodiment 1

[0039]A high-energy carbon-alcohol slurry clean fuel is composed of the following components by weight percentage, 45% of coal powder and 55% of methanol above 300 mesh; 1% of stabilizer and dispersant (1% of the total weight of coal powder and methanol) ) 1%, micron metal powder 0.1%, catalyst 0.1% and desulfurizer 0.5%, the pH value of the mixture in Example 1 was adjusted to between 6.5 and 7.5 with sodium bicarbonate.

Embodiment 2

[0041] A high-energy carbon-alcohol slurry clean fuel is composed of the following components by weight percentage, 47% of coal powder and 53% of methanol above 300 mesh; 1.5% of stabilizer and dispersant (2 ) 2%, micron metal powder 0.2%, catalyst 0.2% and desulfurizer 0.6%, the pH value of the mixture in Example 2 was adjusted to between 6.5 and 7.5 with sodium bicarbonate.

Embodiment 3

[0043] A high-energy carbon-alcohol slurry clean fuel is composed of the following components by weight percentage, 49% of coal powder and 51% of methanol above 300 mesh; 2% of stabilizer and dispersant (2% of the total weight of coal powder and methanol) ) 3%, micron metal powder 0.3%, catalyst 0.2% and desulfurizer 0.7%, the pH value of the mixture in Example 3 was adjusted to between 6.5 and 7.5 with sodium bicarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com