Preparation method of solid microbial inoculant

A technology of solid-state bacterial agent and solid-liquid ratio, which is applied in the preservation of microorganisms, etc., can solve the problems of easy contamination of miscellaneous bacteria and short storage time of bacteria, and achieve the effects of reducing the probability of bacterial infection, long storage time, and improving viability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: prepare solid bacterial agent

[0017] Preparation of the culture medium of the bacteria: add the oil-removing bacteria agent BDB-a (purchased from Nanyang Donghua Engineering Technology Co., Ltd.) into the LB medium and cultivate it for 16 hours. After the cultivation, the bacteria solution is concentrated by sedimentation. 4 times.

[0018] Preparation of solid bacterial agent:

[0019] (1) Sterilize the solid adsorption carrier at 121°C for 30 minutes before use;

[0020] (2) adjust the pH of the concentrated strain culture solution to 5.0, add 2wt‰ potassium sorbate, and mix well;

[0021] (3) According to the ratio of solid-liquid ratio (g / mL) of 1:3, add wheat bran and talcum powder to the above mixed solution, mix evenly, place on a shaker for 1 hour, and set the speed at 50rpm, so that the strains are fully Adsorbed on the carrier;

[0022] (4) The above-mentioned mixed sample is placed in a 35°C oven for constant temperature drying, and the mo...

Embodiment 2

[0025] Embodiment 2: prepare solid bacterial agent

[0026] Preparation of the culture medium of the bacteria: add the oil-removing bacteria agent BDB-a (purchased from Nanyang Donghua Engineering Technology Co., Ltd.) into the LB medium and cultivate it for 16 hours. After the cultivation, the bacteria solution is concentrated by centrifugation. 3 times.

[0027] Preparation of solid bacterial agent:

[0028] (1) Sterilize the solid adsorption carrier at 121°C for 30 minutes before use;

[0029] (2) adjust the pH of the concentrated strain culture solution to 4.0, add 3wt‰ sodium benzoate, and mix well;

[0030] (3) According to the solid-liquid ratio (g / mL) of 1:2, add oat bran and bagasse to the above mixed solution and mix evenly, put it on a shaker for 1 hour, and set the speed at 50rpm, so that the bacteria can be fully adsorbed on on the carrier;

[0031] (4) The above-mentioned mixed sample is placed in a 35°C oven for constant temperature drying, and the moisture ...

Embodiment 3

[0034] Embodiment 3: prepare solid bacterial agent

[0035] Preparation of the culture medium of the bacteria: add the oil-removing bacteria agent BDB-a (purchased from Nanyang Donghua Engineering Technology Co., Ltd.) into the LB medium and cultivate it for 16 hours. The multiple is 2 times.

[0036] Preparation of solid bacterial agent:

[0037] (1) Sterilize the solid adsorption carrier at 121°C for 30 minutes before use;

[0038] (2) adjust the pH of the concentrated strain culture solution to 3.0, add 4wt‰ potassium sorbate, and mix well;

[0039] (3) According to the ratio of solid to liquid (g / mL) of 1:1, add corn flour to the above mixture and mix evenly, put it on a shaker and shake it for 1 hour, and set the speed at 50rpm, so that the bacteria can be fully adsorbed on the carrier ;

[0040] (4) The above-mentioned mixed sample is placed in a 35°C oven for constant temperature drying, and the moisture content reaches 10wt%;

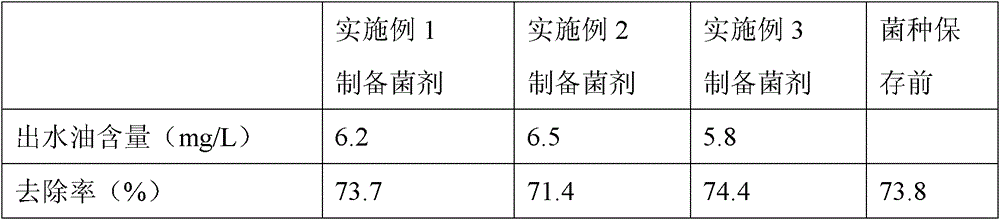

[0041] (5) Take 1 g of the solid mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com