Preparation method of lactobacillus-fermented bean juice with perilla nankinensis

A technology of lactic acid bacteria fermentation and perilla soybean juice, applied in dairy products, milk substitutes, applications, etc., can solve the problems of waste of resources, pollution of the environment, etc., and achieve the effects of saving production costs, high degree of industrialization, and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

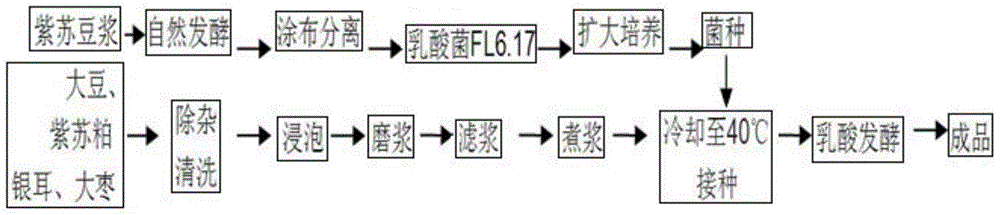

[0026] A kind of preparation method of lactic acid bacteria fermented perilla bean juice, such as figure 1 The shown technological process comprises the following steps:

[0027] Step 1. Isolation and screening of lactic acid bacteria strains

[0028] Ⅰ. Fermentation of soybean milk

[0029] Take soybean and perilla meal with a ratio of 5:3 as raw materials, soak in water at 20°C to 30°C for 6h to 8h, and add water at a ratio of 1:2; the ratio of soaked soybean and perilla meal to water is 1: (3~5), perform pulping, after refining, filter and remove slag through 100-mesh gauze to obtain perilla soybean milk; heat soybean milk at 70°C for 5 minutes, put it into a sterile container and seal it, and naturally cool down to 38°C~ 42°C, keep the temperature at 38°C-42°C for 48 hours, and the soy milk will be in a frozen state after natural fermentation;

[0030] Ⅱ. Preparation of culture medium for isolated lactic acid bacteria

Embodiment 1

[0044] a. Raw material preparation: soybean: perilla meal: white fungus: jujube = 8:5:1:0.5, soaked in water at 20°C for 8 hours, and the ratio of material to water is 1:2;

[0045] Refining and filtering: add 30°C demineralized water to the wet material in step a at a material-to-water ratio of 1:5 for refining to obtain a slurry; filter with 100-mesh gauze to remove slag, and use a colloid mill to refine to 200 mesh.

[0046] c. Cooking pulp: heat all the pulp with water vapor, keep the pulp temperature at 100°C for about 15 minutes, and naturally cool down to 40°C in the fermenter under aseptic conditions;

[0047] d. Inoculation fermentation: when the slurry temperature drops to 40°C, inoculate lactic acid bacteria FL6.17 and bifidobacteria according to 5% of the total amount. Ferment at 40°C for 10h. Quantitative bottling and sealing in an aseptic bottling machine is the finished product, and the finished product needs to be refrigerated.

Embodiment 2

[0049] Raw material preparation: soybean: perilla meal: white fungus: jujube = 7:3:0.8:0.4, soak in water at 25°C for 7 hours, and the ratio of material to water is 1:2.5;

[0050] a. Refining and filtering: Add 25°C demineralized water to the wet material in step a at a material-to-water ratio of 1:4 for refining; filter with 100-mesh gauze to remove slag, and use a colloid mill to refine to 200 mesh.

[0051] c. Cooking pulp: heat all the pulp with water vapor, keep the pulp temperature at 100°C for about 15 minutes, and naturally cool down to 40°C in the fermenter under aseptic conditions;

[0052] d. Inoculation fermentation: when the slurry temperature drops to 40°C, inoculate lactic acid bacteria FL6.17 and bifidobacteria according to 3% of the total amount. Ferment at 41°C for 7h. Quantitative bottling and sealing in an aseptic bottling machine is the finished product, and the finished product needs to be refrigerated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com