Preparation method of bismuth-ferrite-based multiferroic ceramic

A technology of bismuth ferrite and ceramics, which is applied in the field of preparation of bismuth ferrite-based multiferroic ceramics, can solve the problems of large leakage current of bismuth ferrite, easy volatilization of bismuth element, small dielectric constant, etc., and achieve low requirements for experimental equipment, Ease of industrial production and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) At room temperature, according to the chemical formula 0.95BiFeO 3 -0.05BaTiO 3 For raw material Bi 2 o 3 , Fe 2 o 3 、BaCO 3 and TiO 2 Proportionally weighed, added to a ball mill, and ball milled with absolute ethanol as a medium for 3 hours; the obtained mixed solution was dried in a blast drying oven at 120°C for 10 hours to become a solid;

[0025] 2) Add the polyvinyl alcohol aqueous solution to the dried mixed powder in step 1), stir evenly, grind and pass through a 100-mesh sieve to obtain powder; the mass concentration of the polyvinyl alcohol aqueous solution is 5%, and the added The aqueous solution of polyvinyl alcohol accounts for 3% of the total mass of the powder;

[0026] 3) the powder obtained in step 2) is mixed with 100kg / cm in a stainless steel grinding tool 2 The pressure is pressed into a green wafer, and the green wafer is placed in a crucible, and then the crucible is placed in a box-type sintering furnace for sintering; the box-type si...

Embodiment 2

[0029] 1) At room temperature, according to the chemical formula 0.7BiFeO 3 -0.3BaTiO 3 For raw material Bi 2 o 3 , Fe 2 o 3 、BaCO 3 and TiO 2 Proportionally weighed, added to a ball mill, and ball milled with absolute ethanol as a medium for 12 hours; the obtained mixed solution was dried in a blast drying oven at 100°C for 24 hours to become a solid;

[0030] 2) Add the polyvinyl alcohol aqueous solution to the dried mixed powder in step 1), stir evenly, grind and pass through a 200-mesh sieve to obtain powder; the mass concentration of the polyvinyl alcohol aqueous solution is 4%, and the added The aqueous solution of polyvinyl alcohol accounts for 6% of the total mass of the powder;

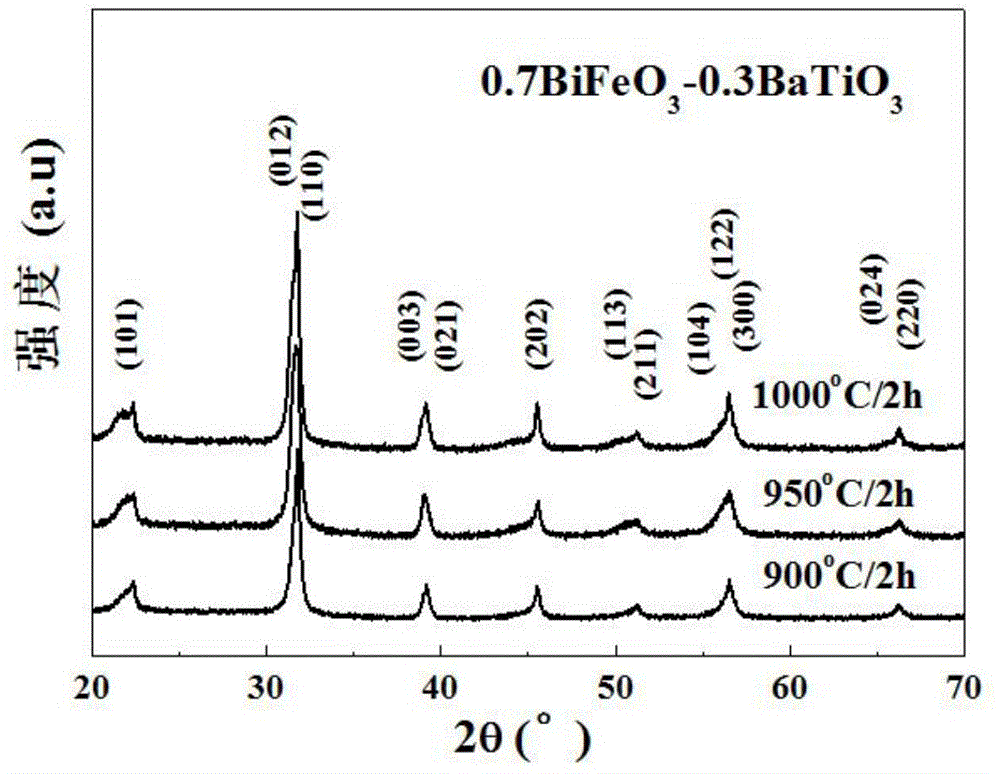

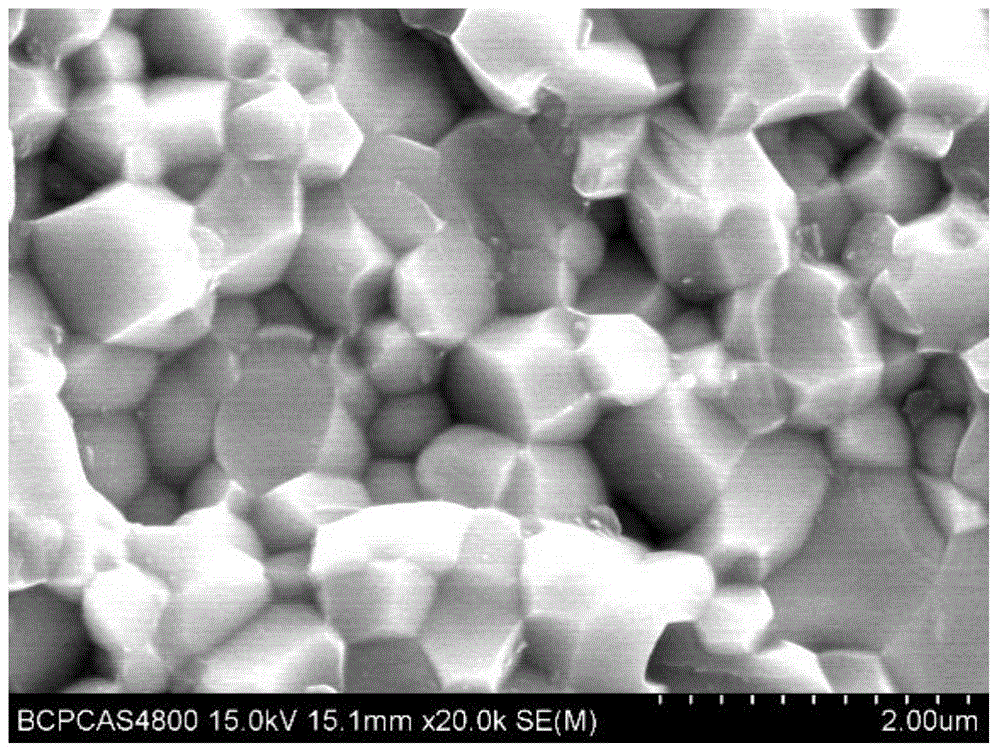

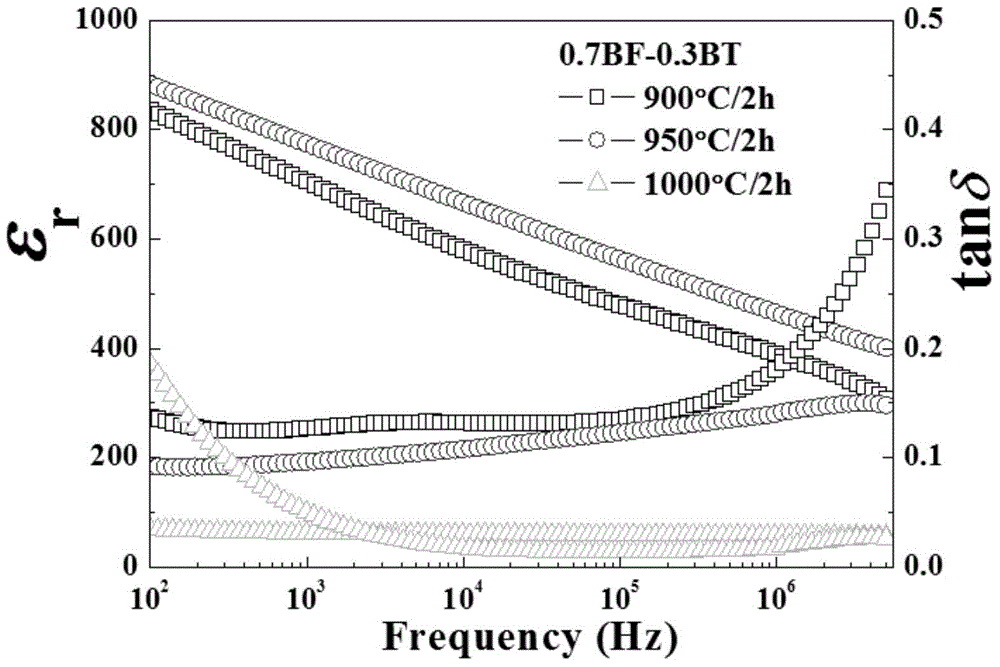

[0031] 3) the powder that step 2) obtains in the stainless steel grinding tool with 250kg / cm 2 The pressure is pressed into a green wafer, and the green wafer is placed in a crucible, and then the crucible is placed in a box-type sintering furnace for sintering; the box-type sintering...

Embodiment 3

[0034] 1) At room temperature, according to the chemical formula 0.7BiFeO 3 -0.3BaTiO 3 For raw material Bi 2 o 3 , Fe 2 o 3 、BaCO 3 and TiO 2Proportionally weighed, added to a ball mill, and ball milled with absolute ethanol as a medium for 12 hours; the obtained mixed solution was dried in a blast drying oven at 100°C for 24 hours to become a solid;

[0035] 2) Add the polyvinyl alcohol aqueous solution to the dried mixed powder in step 1), stir evenly, grind and pass through a 200-mesh sieve to obtain powder; the mass concentration of the polyvinyl alcohol aqueous solution is 4%, and the added The aqueous solution of polyvinyl alcohol accounts for 6% of the total mass of the powder;

[0036] 3) the powder that step 2) obtains in the stainless steel grinding tool with 250kg / cm 2 The pressure is pressed into a green wafer, and the green wafer is placed in a crucible, and then the crucible is placed in a box-type sintering furnace for sintering; the box-type sintering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com