Preparation method of food-grade sodium carboxymethyl cellulose (CMC) with high substitution degree and ultra-low viscosity

A technology of sodium carboxymethyl cellulose and high substitution degree, which is applied in the production field of sodium carboxymethyl cellulose, can solve the problems of not meeting the purity requirements, low purity and low degree of substitution, etc., and achieves high degree of substitution, high transparency, good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

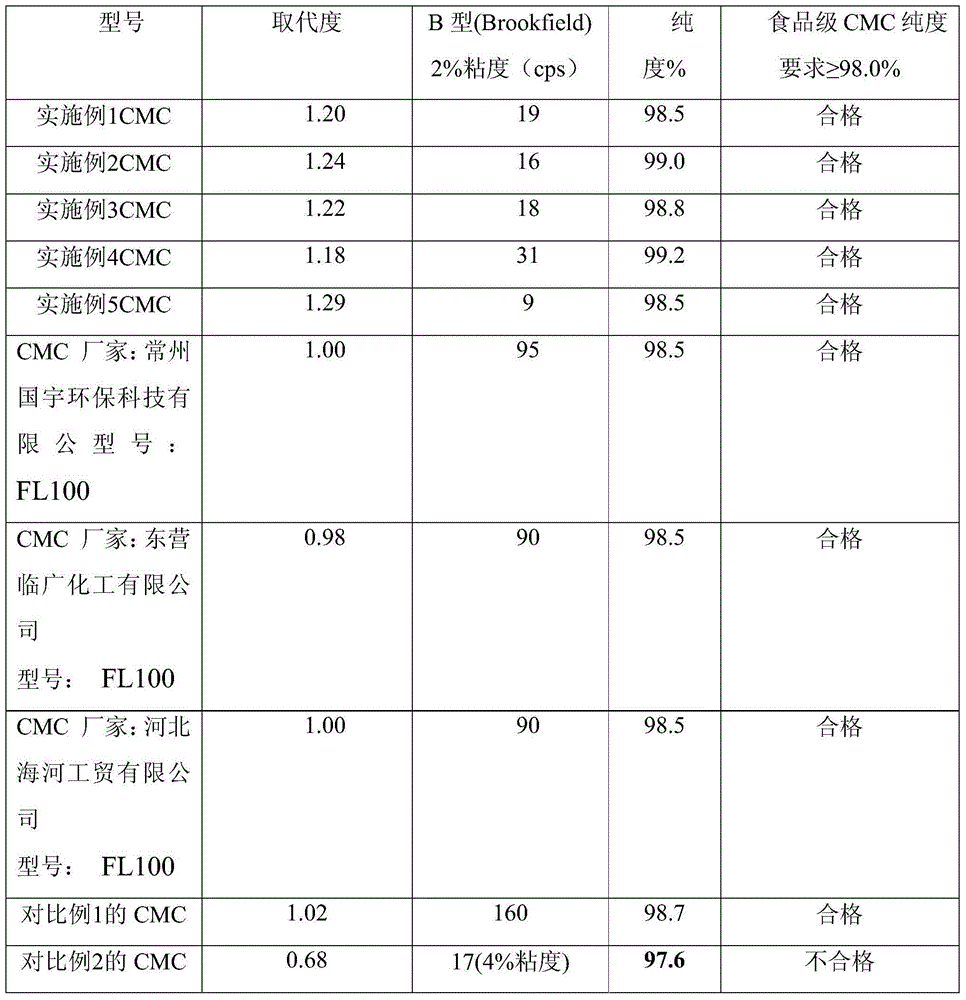

Examples

Embodiment 1

[0041] 1kg of cellulose raw material (the mass ratio of wood pulp cellulose and cotton cellulose is 0.2:1, wherein the degree of polymerization of cotton cellulose is 600, and the degree of polymerization of wood pulp cellulose is 1000) and 2.35kg of mass concentration 48% sodium hydroxide aqueous solution Add 1.75kg of ethanol with a mass concentration of 95% into the kneader at the same time (aqueous sodium hydroxide solution and ethanol are mixed uniformly in advance), then dilute 0.009kg of a hydrogen peroxide solution with a mass concentration of 30% with ethanol and add, stir, and heat up to 35- 45°C, stirring for 60 minutes. Spray 1.9kg of ethanol solution of chloroacetic acid (mass concentration of chloroacetic acid 70%) evenly into the kneader and stir for 20 minutes. Then gradually raise the temperature, carry out etherification reaction, react at 76-80°C for 60 minutes, cool down, discharge, neutralize, wash, deliquify, dry, and pulverize to obtain food-grade high-s...

Embodiment 2

[0043] 1kg of cellulose raw material (the mass ratio of wood pulp cellulose and cotton cellulose is 0.15:1, wherein the degree of polymerization of cotton cellulose is 500, and the degree of polymerization of wood pulp cellulose is 1000) and 2.5kg of 48% sodium hydroxide aqueous solution Add 1.85kg of ethanol with a mass concentration of 95% into the kneader at the same time (aqueous sodium hydroxide solution and ethanol are mixed uniformly in advance), then dilute 0.013kg of a hydrogen peroxide solution with a mass concentration of 30% with ethanol and add it, and then heat up to 35- 45°C, stirring for 70 minutes. Spray 2.0kg of ethanol solution of chloroacetic acid (mass concentration of chloroacetic acid 70%) evenly into the kneader, and stir for 20 minutes. Then gradually raise the temperature, carry out etherification reaction, react at 76-80°C for 60 minutes, cool down, discharge, neutralize, wash, deliquify, dry, and pulverize to obtain food-grade high-substitution ultr...

Embodiment 3

[0045] 1kg of cellulose raw material (the mass ratio of wood pulp cellulose and cotton cellulose is 0.25:1, wherein the degree of polymerization of cotton cellulose is 500, and the degree of polymerization of wood pulp cellulose is 1000) and 2.3kg of 50% sodium hydroxide aqueous solution Add 2kg of ethanol with a mass concentration of 85% into the kneader at the same time (sodium hydroxide aqueous solution and ethanol are mixed uniformly in advance), and then dilute 0.01kg of a hydrogen peroxide solution with a mass concentration of 30% with ethanol and add it. Stir and heat up to 35-45 °C and stirred for 70 minutes. Spray 1.95kg of ethanol solution of chloroacetic acid (mass concentration of chloroacetic acid 70%) evenly into the kneader, and stir for 20 minutes. Then gradually raise the temperature, carry out etherification reaction, react at 76-80°C for 65 minutes, cool down, discharge, neutralize, wash, deliquify, dry, and pulverize to obtain food-grade high-substitution u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com