Method for recycling yeast abandoned after erythritol production

A technology of erythritol and yeast, which is applied in the field of biochemical industry to achieve the effects of avoiding environmental pollution, reducing processing costs and environmental pollution risks, and saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

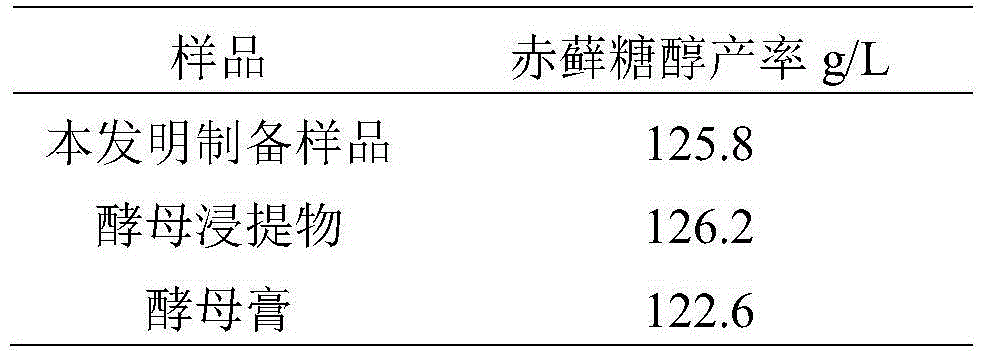

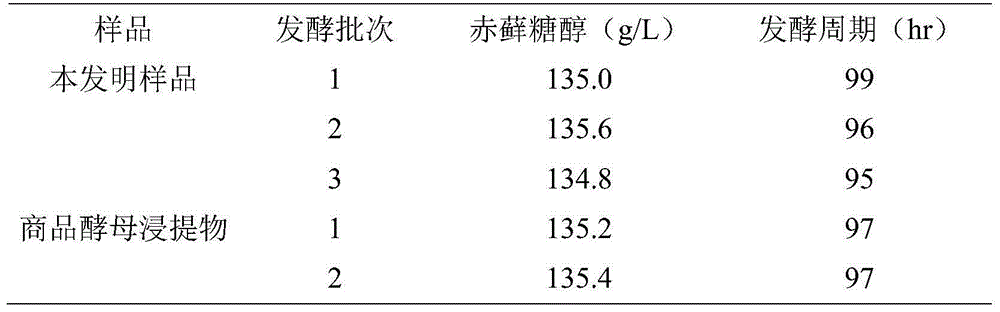

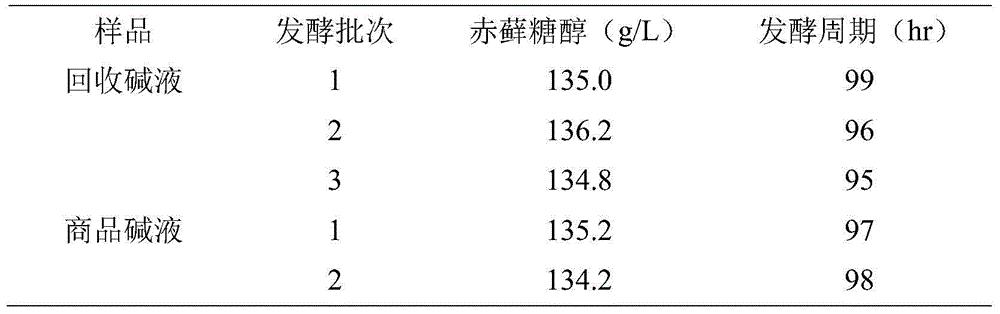

Examples

Embodiment 1

[0024] (1) Centrifuge the yeast cell sludge obtained in the erythritol production fermentation broth thalline separation process, add water, and prepare a suspension with a yeast cell concentration of 13% in g / 100mL; or the thalline separation process The yeast cell suspension obtained by ceramic membrane filtration is adjusted to a suspension with a bacterial cell concentration of 13% in g / 100mL; standby;

[0025] (2) Add 1.6% solid NaCl to the yeast suspension prepared in step (1) in g / 100mL, fully stir and mix, then carry out a high-pressure homogenization under a pressure of 50MPa, and keep the temperature of the feed liquid in the homogenization process Not exceeding 50°C;

[0026] (3) Insulate and autolyze the homogenized feed solution at 50±2°C for 20 hours, and then centrifuge at 4500 rpm to obtain bacterial cell autolyzed clear liquid and autolyzed residue;

[0027] (4) concentrating the cell autolysate obtained in step (3) in a vacuum at 65°C until the solid content...

Embodiment 2

[0032]Get 50L of the ceramic membrane filtration interception solution (thalline cell dry matter concentration 12w / v%) produced in the erythritol production fermentation broth thallus separation process, add 1kg solid NaCl thereinto, carry out high-pressure homogenization after stirring and dissolving, homogeneous The pressure is 45MPa, the homogenization temperature is 50°C, the homogenized cell suspension is incubated at 50°C, stirred and autolyzed for 16 hours, and centrifuged to obtain the autolyzed supernatant and autolyzed residue respectively. The obtained autolyzed supernatant was vacuum concentrated at 60-65° C. to a solid content of 70%, and 5.05 kg of the concentrate (containing 1 kg of NaCl) was obtained. Add 25L 0.2mol / L freshly prepared NaOH solution to the autolyzed residue obtained by centrifugation, stir at 100°C for 1.5 hours, centrifuge, collect the supernatant separately (for pH adjustment in the erythritol fermentation process), and then add 25L 0.2 mol / L ...

Embodiment 3

[0034] Get 60L of ceramic membrane filtration interception solution (yeast cell dry matter concentration 12w / v%) produced during the sterilization process of erythritol production fermentation broth, add 1kg solid NaCl to it, stir and dissolve, then carry out high pressure homogenization, homogenization pressure 50MPa , the homogenization temperature is 50°C, the homogenized cell suspension is incubated at 50°C, stirred and autolyzed for 10 hours, and centrifuged to obtain the autolyzed supernatant and the autolyzed residue respectively. The obtained yeast autolysate suspension was vacuum-concentrated at 60-65° C. to a solid content of 70%, to obtain 5.25 kg of concentrated yeast autolysate (containing 1 kg of NaCl). Add 25L of NaOH solution to the autolyzed yeast residue obtained by centrifugation (the yeast autolyzed residue is treated with secondary alkali to separate lye), stirred at 95°C for 2.0 hours, centrifuged, and the supernatant was collected separately (used for pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com