A Diode Sputtering Coating Equipment for Coating the Inner Wall of a Vacuum Cup

A technology for sputtering coating and coating equipment, applied in the field of vacuum cups, can solve problems such as raising production costs, differences in coating quality, and inability to form industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

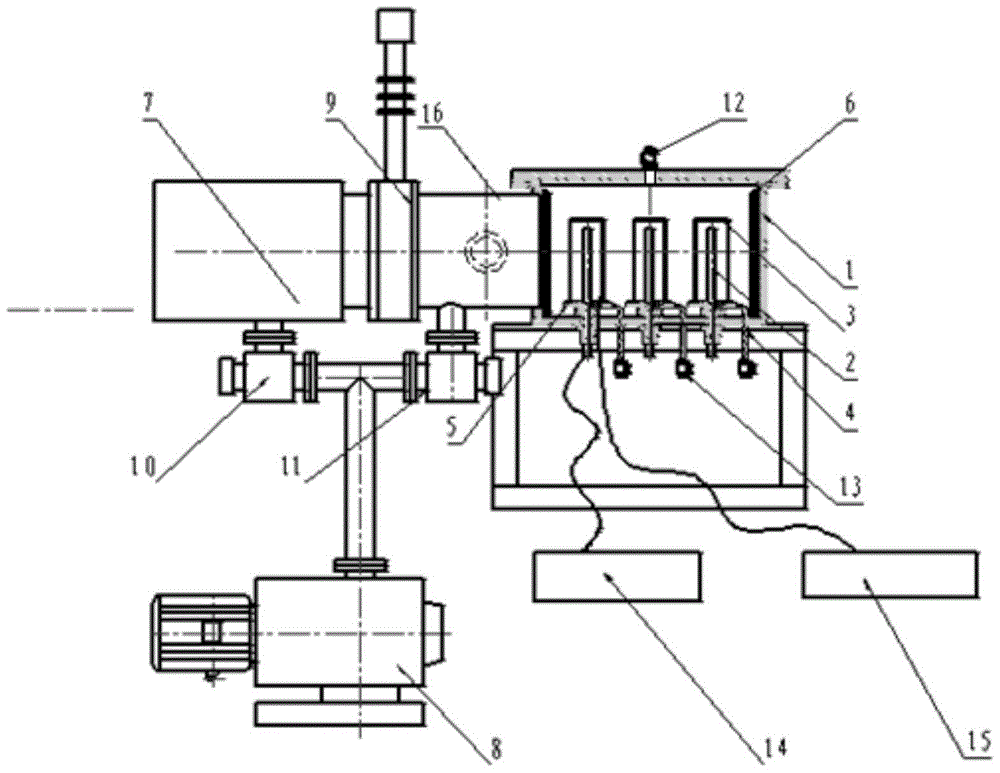

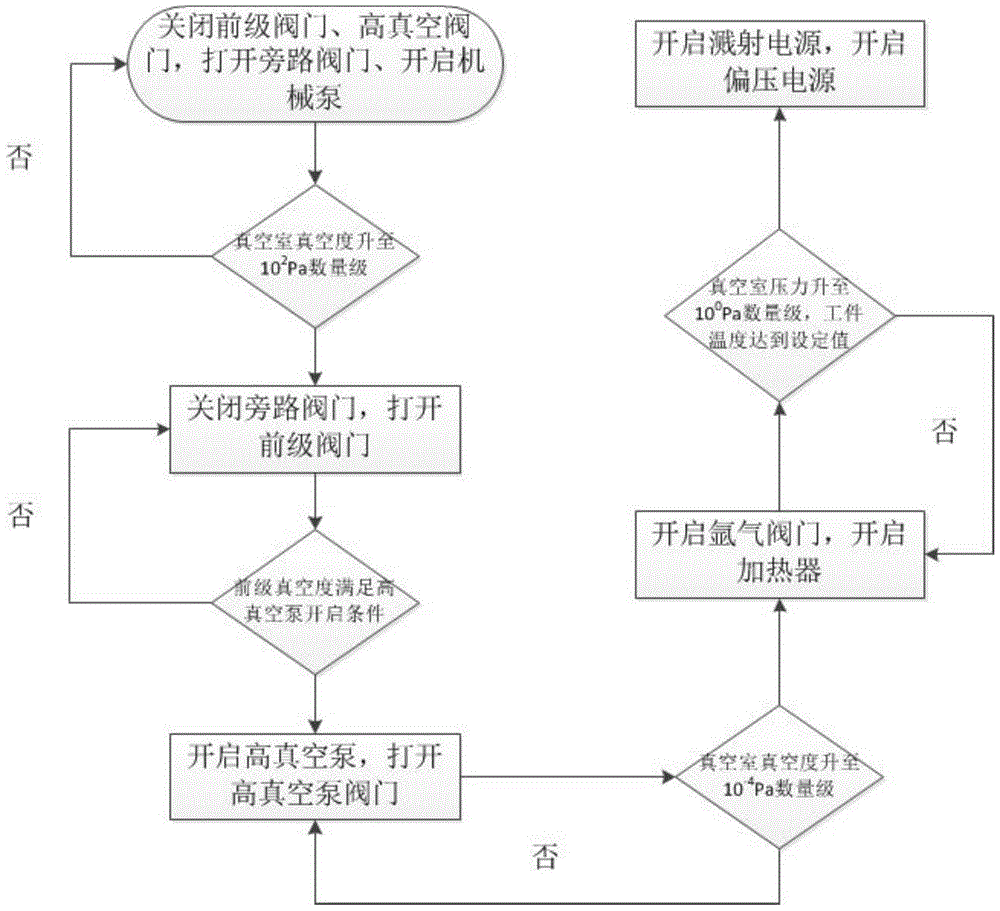

[0032] Use this diode sputtering coating equipment for coating the inner wall of the vacuum cup to plate nano-silver coating on the inner wall of the stainless steel vacuum cup.

[0033] First, ultrasonically clean the inner wall of the stainless steel vacuum cup and the silver electrode and dry them. At the same time, clean the vacuum chamber and vacuum system of the equipment, and place the vacuum cup and silver electrode in the vacuum chamber. Start the vacuum system to evacuate until the vacuum degree of the vacuum chamber rises to 10 -4 Pa order of magnitude; open the heater vacuum cup workpiece to 200 and open the argon valve to feed argon until the vacuum chamber pressure is 10 0 Pa order of magnitude; turn on the sputtering power supply and adjust the voltage to about 4KV, turn on the bias power supply and adjust the voltage to about 100V. The coating time is 20~60 minutes.

Embodiment 2

[0035] The nano-copper alloy coating is plated on the inner wall of the stainless steel vacuum cup by using the diode sputtering coating equipment for coating the inner wall of the vacuum cup.

[0036] First, ultrasonically clean the inner wall of the stainless steel vacuum cup and silver electrodes and dry them. At the same time, clean the vacuum chamber and vacuum system of the equipment, and place the vacuum cup and copper alloy electrodes in the vacuum chamber. Start the vacuum system to evacuate until the vacuum degree of the vacuum chamber rises to 10 -4 Pa order of magnitude, open the heater vacuum cup workpiece to 300 and open the argon valve to feed argon until the vacuum chamber pressure is 10 0 Pa order of magnitude, turn on the sputtering power supply and adjust the voltage to about 6KV, turn on the bias power supply and adjust the voltage to about 150V. The coating time is 10~20 minutes.

[0037] The technology used in the present invention is the two-pole sputt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com