A preparation method of modified zein composite slow-release antibacterial liquid film

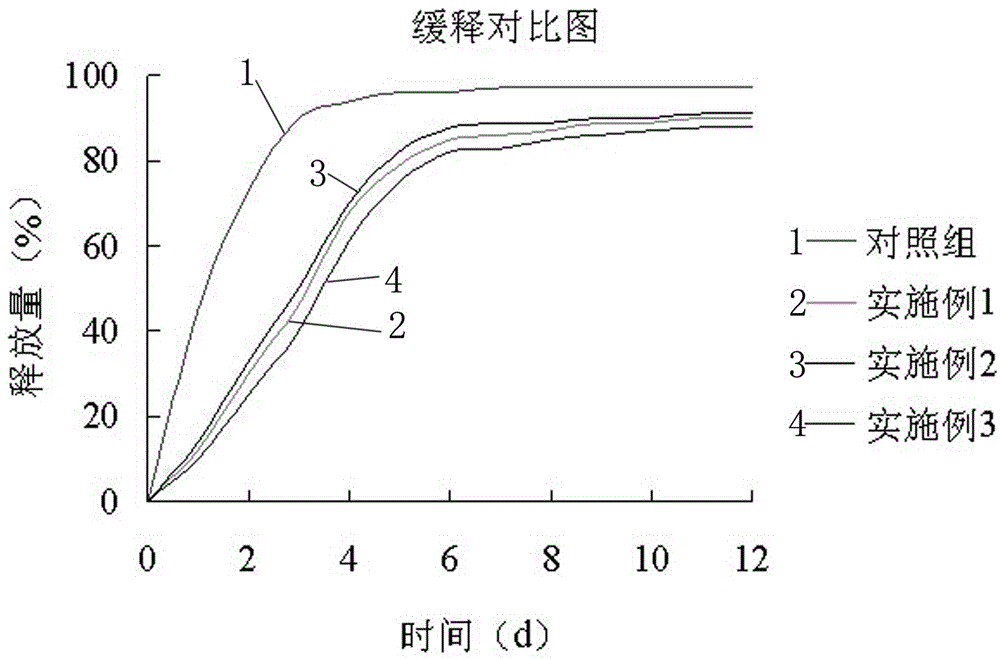

A zein and zein soluble technology, which is applied in plant protein processing, edible seed preservation, meat/fish preservation with chemicals, etc., can solve the problem of poor mechanical properties of zein, affecting the mechanical properties of antibacterial films, and Conducive to industrial production and other issues, to achieve the effect of increasing gloss and water resistance, prolonging the freshness preservation effect, and better slow-release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preliminary modification of zein

[0025] Dissolve 50g of ascorbic acid in 1L of 70% ethanol aqueous solution and mix evenly, add 90g of zein to prepare a mixed solution I, stir at room temperature for 30min to modify the zein; then add the modified mixed solution Ⅰ The mass concentration of equal volume is 1% sodium chloride solution, the modified zein is settled, the sediment is centrifuged, dried and pulverized to obtain the preliminary modified zein powder;

[0026] (2) Secondary modification of zein

[0027] Dissolve 50g of malic acid in 1L of 70% ethanol aqueous solution and mix evenly, add 90g of the preliminary modified zein powder prepared in step (1) to prepare mixed solution II, stir at room temperature for 30min, then add The mass concentration of the modified mixed solution II is 1% sodium chloride solution, and the secondary modified zein protein is settled, the sediment is separated by centrifugation, dried and crushed to obtain the secondary modifie...

Embodiment 2

[0034] (1) Preliminary modification of zein

[0035] Dissolve 70g of ascorbic acid in 1L of 80% ethanol aqueous solution and mix evenly, add 100g of zein to prepare mixed solution I, stir the mixed solution I at room temperature for 35min to modify zein, then add and modify The final mixed solution I is an equal volume of sodium chloride solution with a mass concentration of 0.5%, the modified zein is sedimented, the sediment is centrifuged, dried and pulverized to obtain a preliminary modified zein powder;

[0036] (2) Secondary modification of zein

[0037] Dissolve 70g of malic acid in 1L of ethanol aqueous solution with a volume fraction of 80% and mix evenly, add 110g of the preliminary modified zein powder prepared in step (1) to prepare the mixed solution II, stir the mixed solution II at room temperature for 45min for zein alcohol soluble protein for secondary modification, and then add a 0.5% sodium chloride solution with a mass concentration equal to that of the sec...

Embodiment 3

[0044] (1) Preliminary modification of zein

[0045] Dissolve 60g of ascorbic acid in 1L of ethanol aqueous solution with a volume fraction of 75% and mix evenly, add 95g of zein to prepare a mixed solution I, stir the mixed solution I at room temperature for 40min to modify the zein, then add and modify The final mixed solution I is an equal volume of sodium chloride solution with a mass concentration of 2%, the modified zein is sedimented, the sediment is centrifuged, dried and pulverized to obtain a preliminary modified zein powder;

[0046] (2) Secondary modification of zein

[0047] Dissolve 60g of malic acid in 1L of ethanol aqueous solution with a volume fraction of 75% and mix evenly, add 100g of the preliminary modified zein powder prepared in step (1) to prepare mixed solution II, and stir the mixed solution II at room temperature for 40 minutes to treat zein alcohol soluble protein for secondary modification, then add a sodium chloride solution with a mass concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com