A joint NOx and mercury removal process and device based on sncr-scr combination

A technology of combined removal and SCR system, which is applied in the field of NOx and mercury combined removal process and removal device, can solve the problems of easy volatilization, and achieve the effect of low cost, high efficiency removal and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

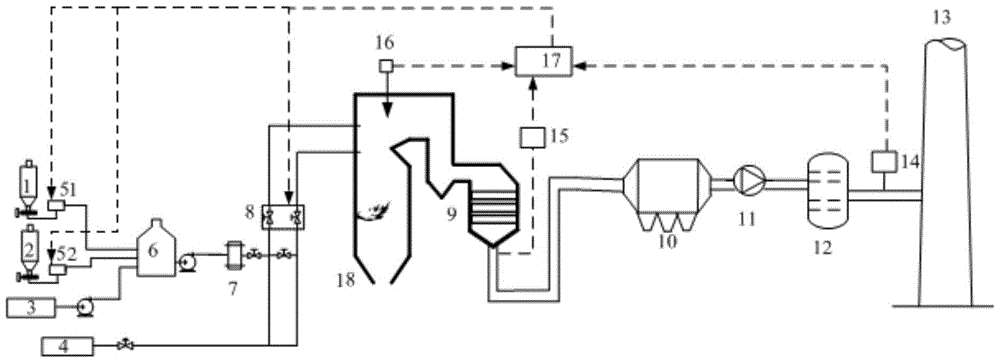

[0032] A NOx and mercury joint removal process based on SNCR-SCR combination of the present invention comprises the following steps,

[0033]1) In the SNCR system, a mixture of urea and ammonium chloride is used as the system reducing agent, and the urea and ammonium chloride are dissolved together through desalinated water to obtain a reducing agent mixed solution with a total mass concentration of the solute of 40-60%; for the first time When mixing, the amount of ammonium chloride is not more than 2% of the total mass of the solute.

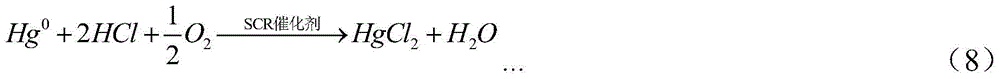

[0034] 2) Spray the mixed reducing agent solution into the furnace 18 at a temperature of 850-1100°C, and use urea and ammonium chloride to thermally decompose NH 3 React with NOx in the flue gas to form N 2 and H 2 O; using NH 4 Cl is heated to decompose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com