Nickel-zinc ferrite material with high saturation magnetic flux density, high DC superposition, and high Curie temperature and its preparation method

A nickel-zinc ferrite, high DC superposition technology, applied in the field of electronic equipment and its preparation, can solve the problems of low application frequency and resistivity of magnetic cores, increased volume of inductors, etc., and achieves wide temperature application range, porosity The effect of reducing and stabilizing the DC superposition adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

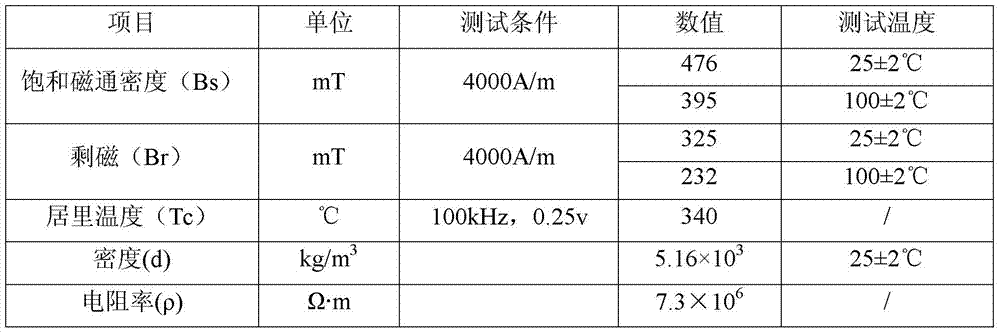

Embodiment 1

[0036] 1. Ingredients and spray granulation:

[0037] Weigh Fe 2 o 3: 50.0mol%; NiO: 26mol%; ZnO: 20.3mol%, CuO: 3.7mol% four kinds of raw materials, then add a certain proportion of deionized water in the sand mill for mixing and crushing, crushing for 30 minutes, and cyclic mixing for 10 Add a certain amount of PVA solution after 10 minutes for spray granulation.

[0038] 2. Pre-burning:

[0039] Put the spray material into the pre-fired furnace, and keep it warm at 840°C for 3 hours for pre-fired.

[0040] 3. Secondary sanding:

[0041] In calcined material, add the following auxiliary components by weight percentage of calcined material: 0.03wt% Bi 2 o 3 , 0.02wt% Nb 2 o 5 , 0.05wt% SnO 2 , 0.02wt%V 2 o 5 , 0.014wt% Co 2 o 3 . Then put the powder into a sand mill and add deionized water for secondary sand milling, the sand milling time is 65 minutes, and the particle size of the powder is controlled at 0.85-0.95 μm.

[0042] 4. Spray granulation and molding:...

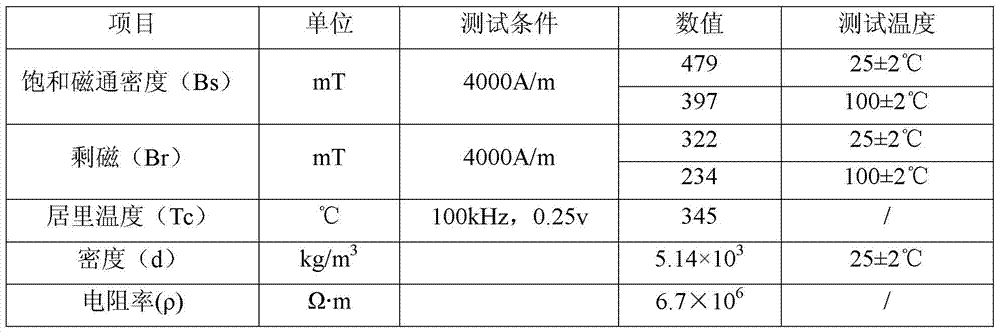

Embodiment 2

[0051] 1. Ingredients and spray granulation:

[0052] Weigh Fe 2 o 3 : 51.2mol%; NiO: 25mol%; ZnO: 19.0mol%, CuO: 4.8mol% four kinds of raw materials, then add a certain proportion of deionized water in the sand mill for mixing and crushing, crushing for 30 minutes, and circulating mixing for 10 Add a certain amount of PVA solution after 10 minutes for spray granulation.

[0053] 2. Pre-burning:

[0054] Put the spray material into the pre-burning furnace, and keep it warm at 850°C for 3 hours for pre-burning.

[0055] 3. Secondary sanding:

[0056] In calcined material, add the following auxiliary components by weight percentage of calcined material: 0.03wt% Bi 2 o 3 , 0.03wt% Nb 2 o 5 , 0.06wt% SnO 2 , 0.03wt%V 2 o 5 , 0.024wt% Co 2 o 3 . Then put the powder into a sand mill and add deionized water for secondary sand grinding. The sand grinding time is 70 minutes, and the particle size of the powder is controlled at 0.85-0.95 μm.

[0057] 4. Spray granulation ...

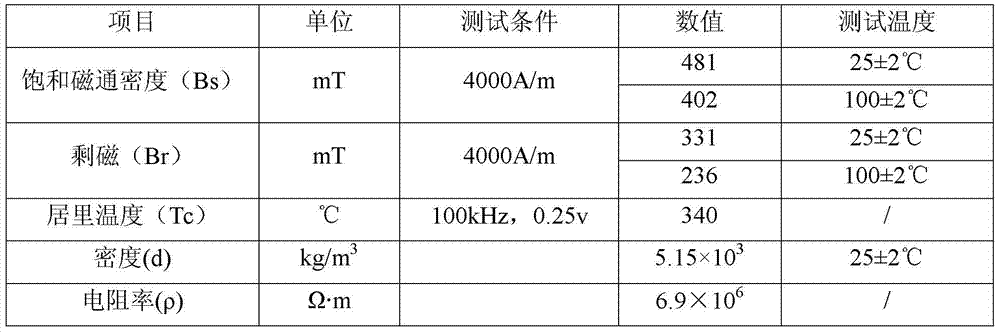

Embodiment 3

[0066] 1. Ingredients and spray granulation:

[0067] Weigh Fe 2 o 3 : 48.5mol%; NiO: 27mol%; ZnO: 21.5mol%, CuO: 3mol% four kinds of raw materials, then add a certain proportion of deionized water in the sand mill for mixing and crushing, crushing for 30 minutes, and circulating mixing for 10 minutes Finally, a certain amount of PVA solution is added for spray granulation.

[0068] 2. Pre-burning:

[0069] Put the spray material into the pre-fired furnace, and keep it warm at 860°C for 3 hours for pre-fired.

[0070] 3. Secondary sanding:

[0071] In calcined material, add the following auxiliary components by weight percentage of calcined material: 0.03wt% Bi 2 o 3 , 0.04wt%Nb 2 o 5 , 0.03wt% SnO 2 , 0.05wt%V 2 o 5 , 0.010wt% Co 2 o 3 . Then put the powder into a sand mill and add deionized water for secondary sand milling. The sand milling time is 60 minutes, and the particle size of the powder is controlled at 0.85-0.95 μm.

[0072] 4. Spray granulation and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com