Anthracene-ring bis (triazol 1 yl) copper perchlorate complex with catalyst phenylboronic acid and preparation method thereof

An anthracycline bistriazole copper and copper complex technology is applied in the field of inorganic synthesis, can solve problems such as expensive palladium catalyst, and achieve the effects of simple and easy reaction operation, high reaction yield and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

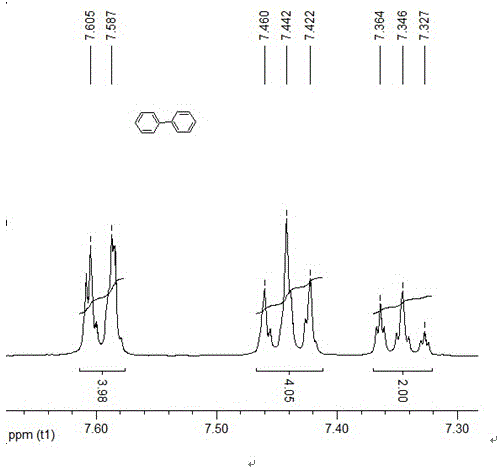

[0028]Preparation of 1-[9-(1H-1,2,4-triazol-1-yl)anthracen-10-yl]-1H-1,2,4-triazole (tatrz) ligand

[0029] The preparation method of 1-[9-(1H-1,2,4-triazol-1-yl)anthracene-10-yl]-1H-1,2,4-triazole of the present invention is characterized in In the "one-pot method", the organic compound is prepared by heating 9,10-dibromoanthracene, triazole, potassium carbonate and copper oxide in a polar solvent; wherein 9,10-dibromoanthracene: three Azole: potassium carbonate: the molar ratio of copper oxide is 2:10:30:1;

[0030]

[0031] In the present invention, the molar ratio of 9,10-dibromoanthracene (I): triazole (II): potassium carbonate: copper oxide is preferably 2:10:30:1; the reaction temperature is 80-200°C, and the reaction time is 12-120 hours .

[0032] The more detailed preparation method of the present invention is as follows:

[0033] A preparation method of 1-[9-(1H-1,2,4-triazol-1-yl)anthracen-10-yl]-1H-1,2,4-triazole is characterized in that, in In a polar solv...

Embodiment 2

[0037] Cu(ClO 4 ) 2 and 1-[9-(1H-1,2,4-triazol-1-yl)anthracen-10-yl]-1H-1,2,4-triazole (tatrz) in a molar ratio of 1: 1;

[0038] tatrz (0.0312 g, 0.1 mmol) and Cu(ClO 4 ) 2 (0.0370 g, 0.1 mmol) in H 2 O (6 mL) and CH 3 OH (4 mL) was stirred in a mixed solvent at room temperature for half an hour and then filtered, and the filtrate was volatilized at room temperature as yellow rod-shaped crystals analyzed by X-ray single crystal diffraction. Yield: 35% (calculated based on tatrz). Elemental analysis (C 40 h 44 Cl 2 CuN 12 o 14 ) Theoretical value (%): C, 45.70; H, 4.22; N, 15.99. Found: C, 45.75; H, 4.12; N, 15.89.

[0039] Example 2

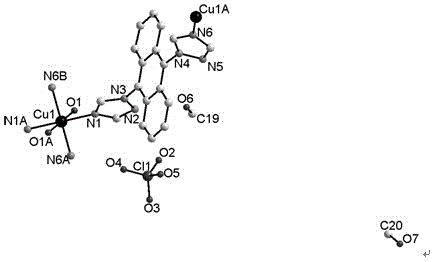

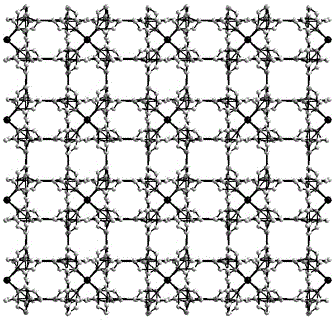

[0040] The crystal structure was determined using an APEX II CCD single crystal diffractometer, using graphite monochromatized Mokα rays (λ = 0.71073 ?) as the incident radiation, and ω -2 θ Diffraction points are collected by scanning, and the unit cell parameters are obtained by least square method correction. The crysta...

Embodiment 3

[0044] Cu(ClO 4 ) 2 and 1-[9-(1H-1,2,4-triazol-1-yl)anthracen-10-yl]-1H-1,2,4-triazole (tatrz) in a molar ratio of 1: 1;

[0045] We also tried other ratios such as Cu(ClO 4 ) 2 and 1-[9-(1H-1,2,4-triazol-1-yl)anthracen-10-yl]-1H-1,2,4-triazole (tatrz) in a molar ratio of 2: 1, no matter how long the hydrothermal reaction time is, no crystalline compound can be obtained. Therefore Cu(ClO 4 ) 2 and 1-[9-(1H-1,2,4-triazol-1-yl)anthracen-10-yl]-1H-1,2,4-triazole (tatrz) in a molar ratio of 1: 1 is the best response ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com