Polyacrylic acid emulsion hydrophobic coating material with low fluorine content and preparation method thereof

A technology of polyacrylic acid emulsion and hydrophobic coating, applied in the direction of coating, etc., can solve the problem of high fluorine content, achieve low cost, transparent coating, and reduce material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment one: Preparation of Low Fluorinated Acrylic Emulsion

[0033] Add 4.00 g of pre-emulsified seed monomer methyl methacrylate and ammonium persulfate aqueous solution into a three-necked flask equipped with a stirring and reflux condenser, and add 18.00 g of methacrylic acid to the core layer monomer after a constant temperature reaction at 75°C for 30 minutes. Methyl ester, after 1 hour of dropwise addition, continue to add 1.60 g of dodecafluoroheptyl methacrylate, 9.30 g of butyl acrylate, and 7.90 g of methyl methacrylate dropwise for shell monomers after 1 hour of heat preservation, and add dropwise ammonium persulfate aqueous solution at the same time After 1 hour of dropwise addition, lift the stirrer slightly, raise the temperature to 80°C and continue the reaction for 2 hours, cool to room temperature, filter and remove the filter residue, adjust the pH of the emulsion to about 7 with ammonia water, and obtain a stable fluorine-containing acrylic aci...

Embodiment 2

[0037] Embodiment two: Preparation of Low Fluorinated Acrylic Emulsion

[0038]This embodiment is basically the same as that of Embodiment 1, except that hexafluorobutyl methacrylate is used as the fluorine-containing monomer in the shell layer. The amount of all monomers remains unchanged. That is, add 4.00 g of pre-emulsified seed monomer methyl methacrylate and ammonium persulfate aqueous solution into a three-necked flask equipped with a stirring and reflux condenser, react at a constant temperature of 75 ° C for 30 minutes, and then dropwise add 18.00 g of methyl monomer for the core layer Methyl acrylate, after 1 hour of dropwise addition, continue to add 1.60 g of hexafluorobutyl methacrylate, 9.30 g of butyl acrylate, and 7.90 g of methyl methacrylate dropwise for shell monomers after 1 hour of heat preservation, and add dropwise ammonium persulfate aqueous solution at the same time After 1 hour of dropwise addition, lift the stirrer slightly, raise the temperature ...

Embodiment 3

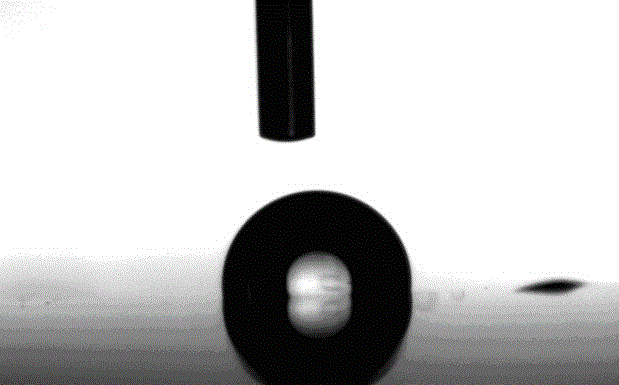

[0042] Embodiment three: Constant temperature film formation

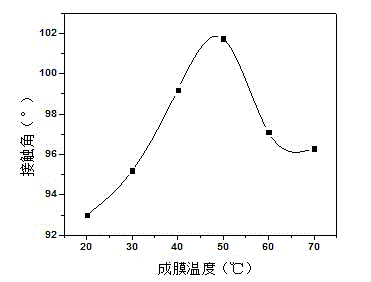

[0043] The emulsion in Example 1 was first diluted with deionized water to a solid content of 15%, and then a uniform emulsion film was coated on a cleaned glass sheet. Put it in an oven, let it stand at 50°C for 12 hours, take it out and cool it to room temperature, and then a hydrophobic coating of acrylic resin with low fluorine content is obtained. The contact angle is 101.8°. The photo of the contact angle is as follows: figure 1 Shown, wherein the consumption of fluorine-containing monomer is only 4% of monomer total amount. DSC test results showed that the Tg of the resin was 41.2°C. Increasing the film-forming temperature would intensify the molecular movement, increase the migration speed of -CF groups to the surface, decrease the surface energy of the coating film, and increase the contact angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com