7A85 aluminium alloy hot-top casting process and 7A85 aluminium alloy ingot

A technology of hot top casting and aluminum alloy, applied in the field of metal materials, can solve the problem of low pass rate of ingot inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

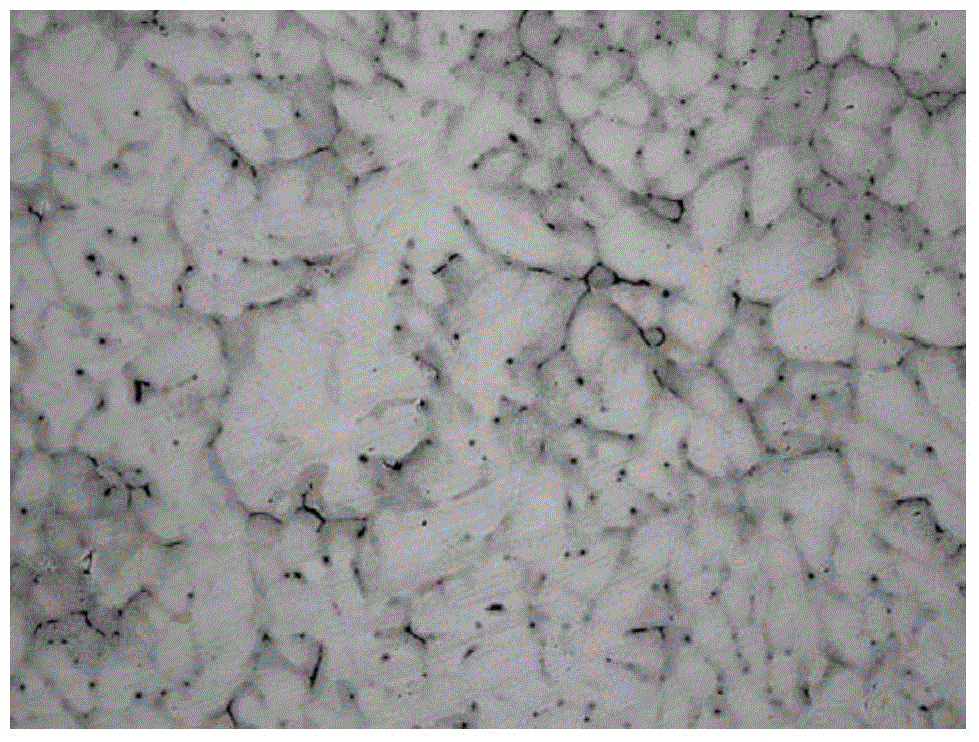

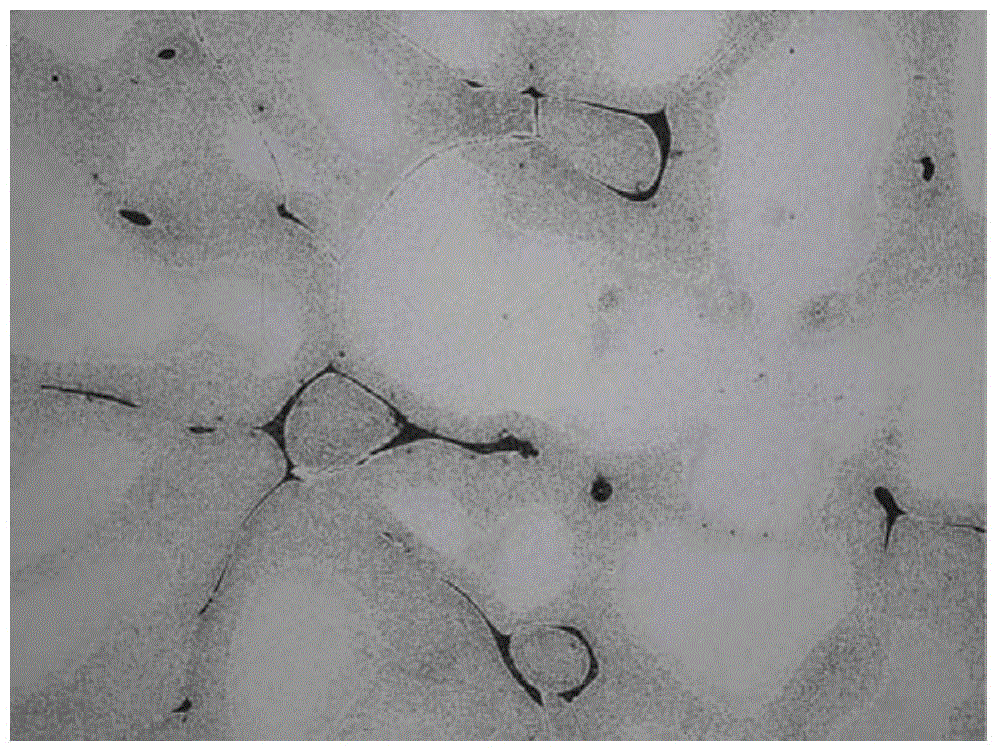

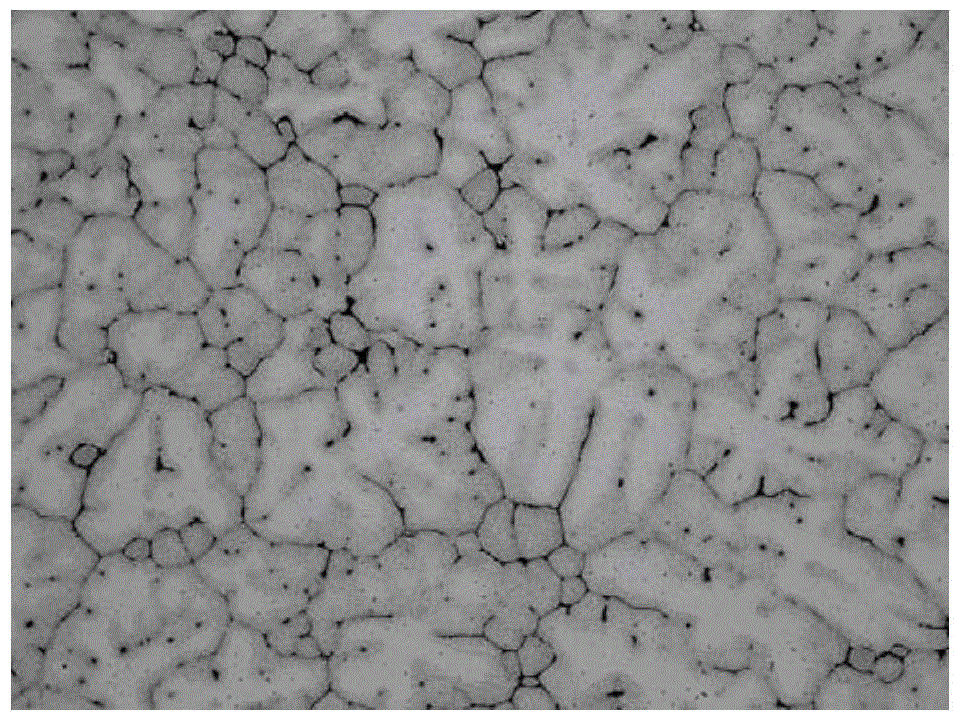

Image

Examples

Embodiment 1

[0097] Produce 7A85 aluminum alloy with an ingot length of 4200mm and an ingot specification of Φ850. 4 castings at one time, considering the oxidation loss of 5%, the density of the alloy is 2800kg / m 3 , then calculate the total feeding amount = π × 0.85 2 / 4×4.2×4×(1+5%)×2800≈28400kg.

[0098] Sprinkle 65kg of 2# solvent powder evenly in the melting furnace, and then load 482kg of pure Cu plate, 2156kg of pure Zn ingot, 142kg of Al-Ti master alloy, 851kg of Al-Zr master alloy and 24287kg of Al ingot in order from small to large. The small pieces of material are loaded first, and then the large pieces of material. At the same time, the intermediate alloy with a high melting point is installed in the middle and upper layers, and the metal that is easy to burn is installed in the middle layer. The hearth temperature of the smelting furnace is controlled at ≤1050°C, and the melt temperature is controlled at ≤770°C. When the melt softens, collapses and flattenes, sprinkle 130kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com