A method for improving the quality of copper-zinc-tin-sulfur thin films for solar cells

A solar cell, copper-zinc-tin-sulfur technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as efficiency reduction, poor film quality, and insufficient absorption, and achieve improved flatness, improved conversion efficiency, and high crystal quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

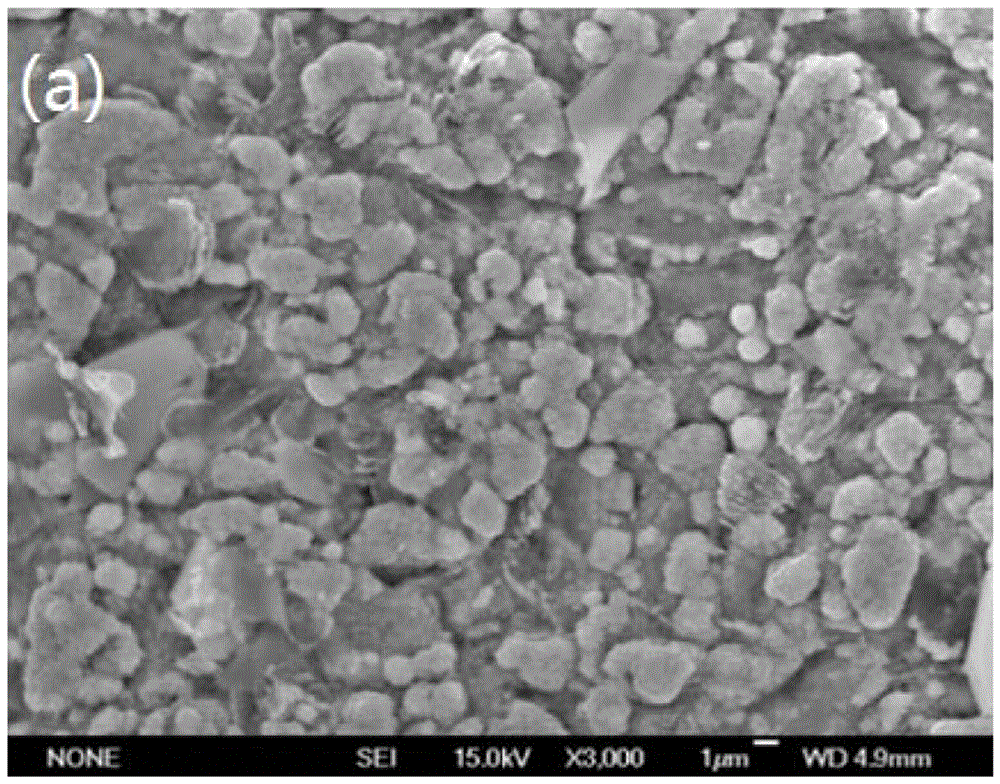

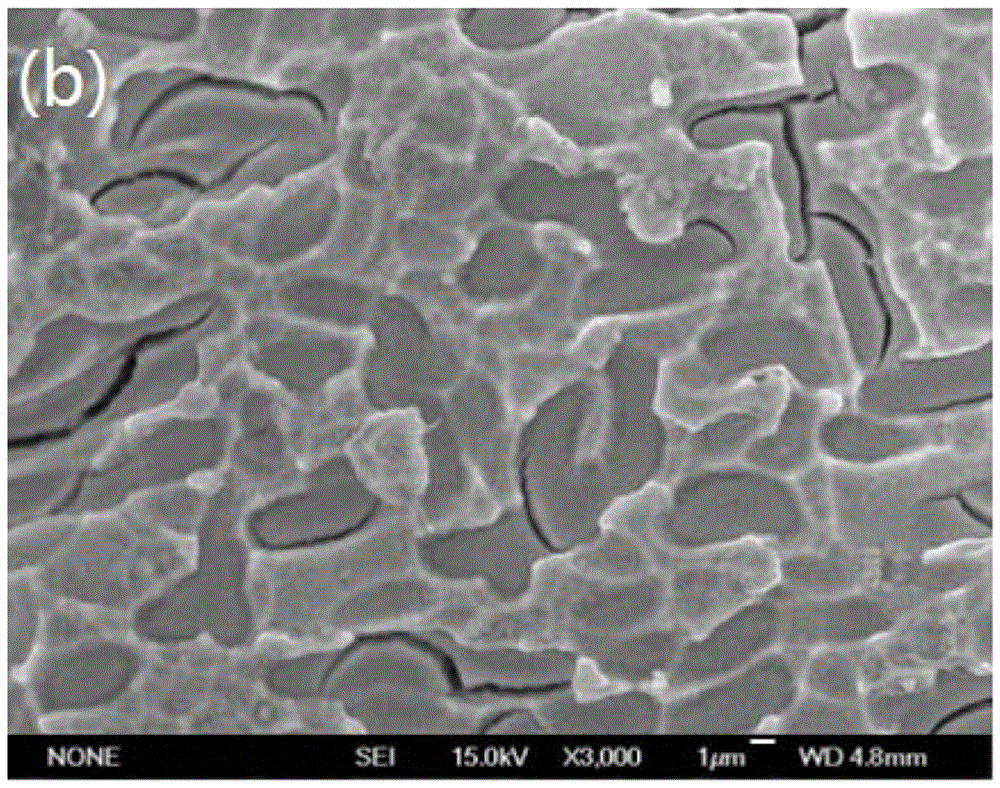

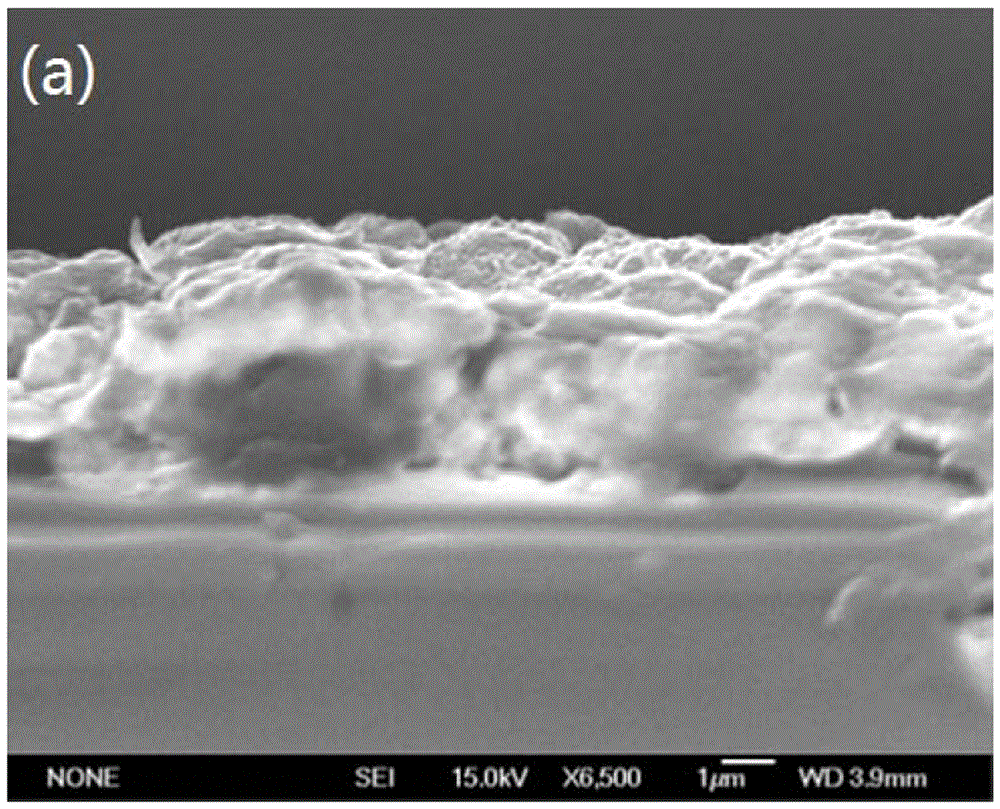

[0022] A method for improving the quality of a copper-zinc-tin-sulfur thin film used in a solar cell, comprising the following steps, selenization: at 500° C., using selenium powder to carry out selenization to the initial copper-zinc-tin-sulfur thin film, and the selenization time is 40min, Then cool to room temperature; vulcanization: vulcanize the selenized copper zinc tin sulfur film at 500°C under sulfur powder, the vulcanization time is 40min, and then cool to room temperature; secondary selenization: at 500°C, use selenium powder Secondary selenization is performed on the sulfided copper-zinc-tin-sulfur film, the selenization time is 20min, and then cooled to room temperature; Secondary vulcanization, the vulcanization time is 13min, and then cooled to room temperature.

[0023] In described selenization, secondary selenization process, add Sn powder in selenium powder, the mass ratio of the quality of Sn powder and selenium powder is 1: 1; In described vulcanization, s...

Embodiment 2

[0034] Example 2 is the same initial copper-zinc-tin-sulfur thin film used in example 1.

[0035] A method for improving the quality of a copper-zinc-tin-sulfur thin film used in a solar cell, comprising the steps of selenization: at 550° C., using selenium powder to selenize the initial copper-zinc-tin-sulfur thin film, and the selenization time is 20 minutes, Then cool to room temperature; vulcanization: vulcanize the selenized copper-zinc-tin-sulfur film at 550°C under sulfur powder, the vulcanization time is 40min, and then cool to room temperature; secondary selenization: at 550°C, use selenium powder Secondary selenization is performed on the sulfided copper-zinc-tin-sulfur film, the selenization time is 20min, and then cooled to room temperature; Secondary vulcanization, the vulcanization time is 5min, and then cooled to room temperature.

[0036] In described selenization, secondary selenization process, add Sn powder in solid selenium source, the mass ratio of the qu...

Embodiment 3

[0038] Example 3 is the same initial copper-zinc-tin-sulfur thin film used in example 1.

[0039] A method for improving the quality of a copper-zinc-tin-sulfur thin film used in a solar cell, comprising the following steps, selenization: at 525° C., using selenium powder to carry out selenization to the initial copper-zinc-tin-sulfur thin film, and the selenization time is 30min, Then cool to room temperature; vulcanization: vulcanize the selenized copper zinc tin sulfur film at 525°C under sulfur powder, the vulcanization time is 30min, and then cool to room temperature; secondary selenization: at 525°C, use selenium powder Secondary selenization is carried out on the copper-zinc-tin-sulfur thin film after sulfidation, and the selenization time is 15 minutes, and then cooled to room temperature; Secondary vulcanization, the vulcanization time is 10min, and then cooled to room temperature.

[0040] In described selenization, secondary selenization process, add Sn powder in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com