Method for preparing lithium ion battery porous electrode based on 3D printing technology

A technology for lithium-ion batteries and porous electrodes, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unfavorable rate characteristics, specific capacity, difficulty in intercalation and extraction of lithium ions, and excessively thick electrode lines, so as to improve lithium storage performance , high controllability, and the effect of improving ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

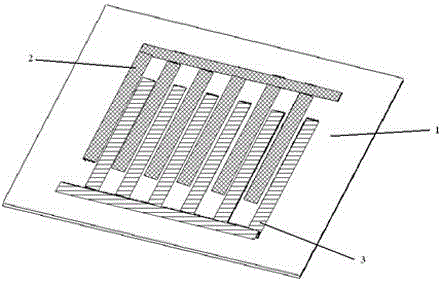

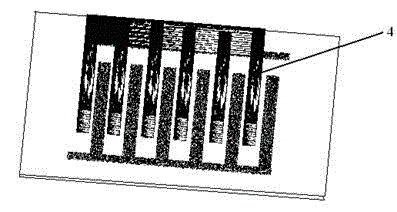

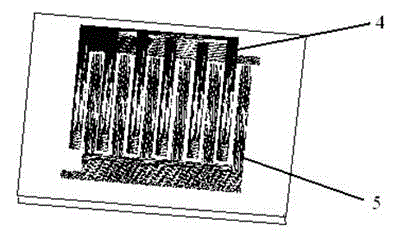

Image

Examples

Embodiment 1

[0030] (1) Weigh 2g lithium iron phosphate and ultrasonically dissolve it into 80ml deionized water and 10ml ethylene glycol; weigh 2g manganese oxide and ultrasonically dissolve it into the first mixed solution g PMMA (polymethyl methacrylate), 80ml deionized water And in the mixed solution of 30ml ethylene glycol;

[0031] (2) Transfer the above two solutions to a ball mill for 12 hours, then transfer to a centrifuge, process at 3500rmp for 2 minutes, filter to remove large particles, and then transfer the filtrate to a centrifuge for 1 hour at 3000rmp filter;

[0032] (3) Disperse the lithium iron phosphate and manganese oxide obtained after the above filtration into a mixed solution composed of glycerol, HPC, HEC and deionized water and stir vigorously for 1 hour. The glycerol, HPC, HEC and deionized water used The mass fractions of ionized water are 50-65%, 15-20%, 1-5% and 20-30% respectively;

[0033] (4) Take a glass sheet with a specification of 20×10mm as t...

Embodiment 2

[0039] (1) Weigh 3g lithium iron phosphate and ultrasonically dissolve it into 90ml deionized water and 20ml ethylene glycol; weigh 3g manganese oxide and ultrasonically dissolve it into the second mixed solution g PMMA (polymethyl methacrylate), 100ml deionized water And in the mixed solution of 40ml ethylene glycol;

[0040] (2) Transfer the above two solutions to a ball mill for 16 hours, then transfer to a centrifuge, process at 4000rmp for 3 minutes, filter to remove large particles, and then transfer the filtrate to a centrifuge for 2 hours at 3500rmp filter;

[0041] (3) Disperse the lithium iron phosphate and manganese oxide obtained after the above filtration into a mixed solution composed of glycerol, HPC, HEC and deionized water and stir vigorously for 2 hours. The glycerol, HPC, HEC and deionized water used The mass fractions of ionized water are 50-65%, 15-20%, 1-5% and 20-30% respectively;

[0042] (4) Take a glass sheet with a specification of 20×10mm ...

Embodiment 3

[0048] (1) Weigh 4g of lithium iron phosphate and ultrasonically dissolve it into 100ml of deionized water and 30ml of ethylene glycol; In the mixed solution of ethylene glycol;

[0049] (2) Transfer the above two solutions to a ball mill for 18 hours, then transfer to a centrifuge, process at 4000rmp for 4 minutes, filter to remove large particles, and then transfer the filtrate to a centrifuge for 3 hours at 4000rmp filter;

[0050] (3) Disperse the lithium iron phosphate and manganese oxide obtained after the above filtration into a mixed solution composed of glycerol, HPC, HEC and deionized water and stir vigorously for 3 hours. The glycerol, HPC, HEC and deionized water used The mass fractions of ionized water are 50-65%, 15-20%, 1-5% and 20-30% respectively;

[0051] (4) Take a glass sheet with a specification of 20×10mm as the substrate, and use the mask plate to cover the evaporation coating technology to prepare patterned gold electrodes on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com