Magnet surface treatment method

A surface treatment and magnet technology, applied in metal material coating process, superimposed layer plating, coating and other directions, can solve the problems of anti-corrosion effect not as good as hexavalent chromium passivation, environmental pollution, etc., achieve excellent anti-corrosion effect, combined with The effect of good strength and good anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

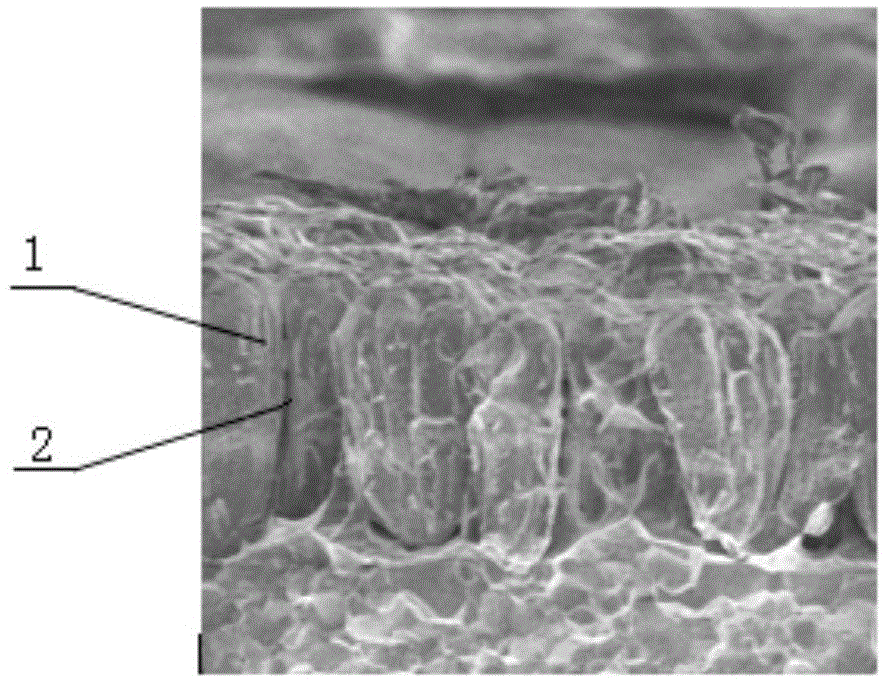

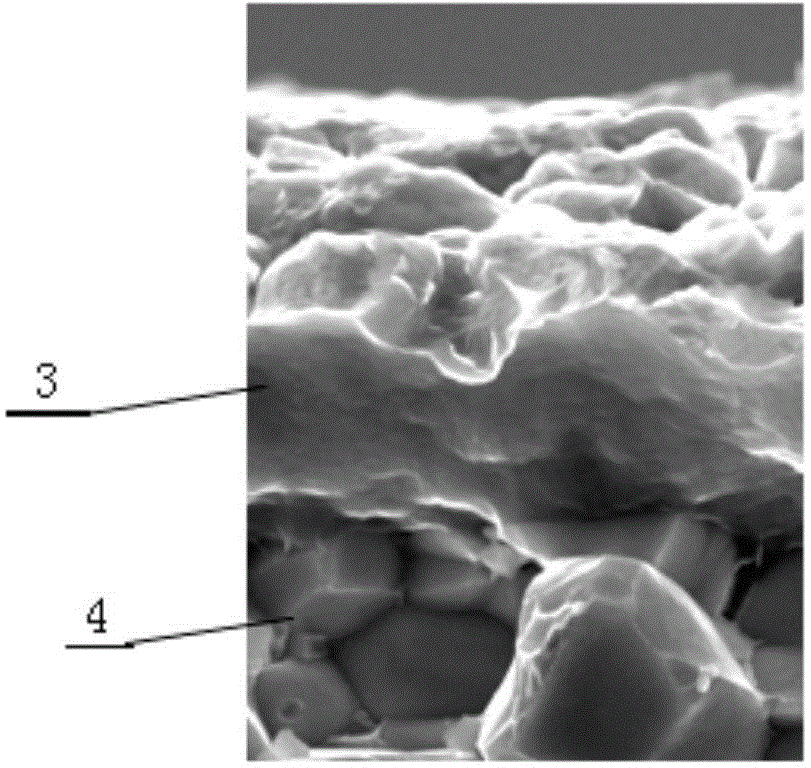

[0026] Take 20 pieces of sintered NdFeB permanent magnets (the brand is N35SH) with a size of 40mm×8mm×5mm. Chamfering R>0.2mm, after 240 mesh corundum blasting pressure 0.5 ~ 0.6Mpa pretreatment for 2min. Then vacuum ion evaporation coating is carried out, and the thickness of the coated film is 8-10 μm. Choose 10 pieces of them to conduct the Highly Accelerated Humidity and Heat Stress Test (HAST) (120°C, 2atm, saturated humidity), and observe after 160h that the magnets are intact, and there is no change such as peeling and blistering on the surface. Choose 10 of them for the neutral salt spray (NSS) test. After 72 hours, the magnet is intact and there is no red rust on the surface.

Embodiment 2

[0028] Take 20 pieces of sintered NdFeB permanent magnets (the brand is N35SH) with a size of 40mm×8mm×5mm. Chamfering R>0.2mm, vacuum ion evaporation coating after degreasing and rust removal, the thickness of the coating is 8-10μm. Choose 10 of them for HAST test (120℃, 2atm, saturated humidity), after 160 hours, the magnets are intact, and the surface has no changes such as peeling and blistering. Choose 10 of them for NSS test. After 72 hours, the magnet is intact and there is no red rust on the surface.

Embodiment 3

[0030] Take 20 pieces of sintered NdFeB permanent magnets (brand N33SH) with a size of 40mm×8mm×5mm. Chamfering R>0.2mm, vacuum ion evaporation coating after degreasing and rust removal, the thickness of the coating is 8-10μm, and then 3+ passivation treatment in the trivalent chromate passivation solution for 5 minutes, and let it air for 8 hours at room temperature. Choose 10 pieces from them for HAST test (120°C, 2atm, saturated humidity), observe after 200 hours, the magnet is intact, and there is no change such as peeling and blistering on the surface. In addition, 10 pieces were selected for NSS test. After 96 hours, the magnet was intact and there was no red rust on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com