Preparation method of porous ferroferric oxide composite nanometre microspheres efficiently loaded with pharmorubicin

A technology of ferric oxide and epirubicin, which is applied to medical preparations with non-active ingredients, medical preparations containing active ingredients, drug combinations, etc., which can solve the problems of poor drug release effect, cumbersome preparation process, and lack of targets. tropism and other issues, to achieve the effect of low cost, simple process and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

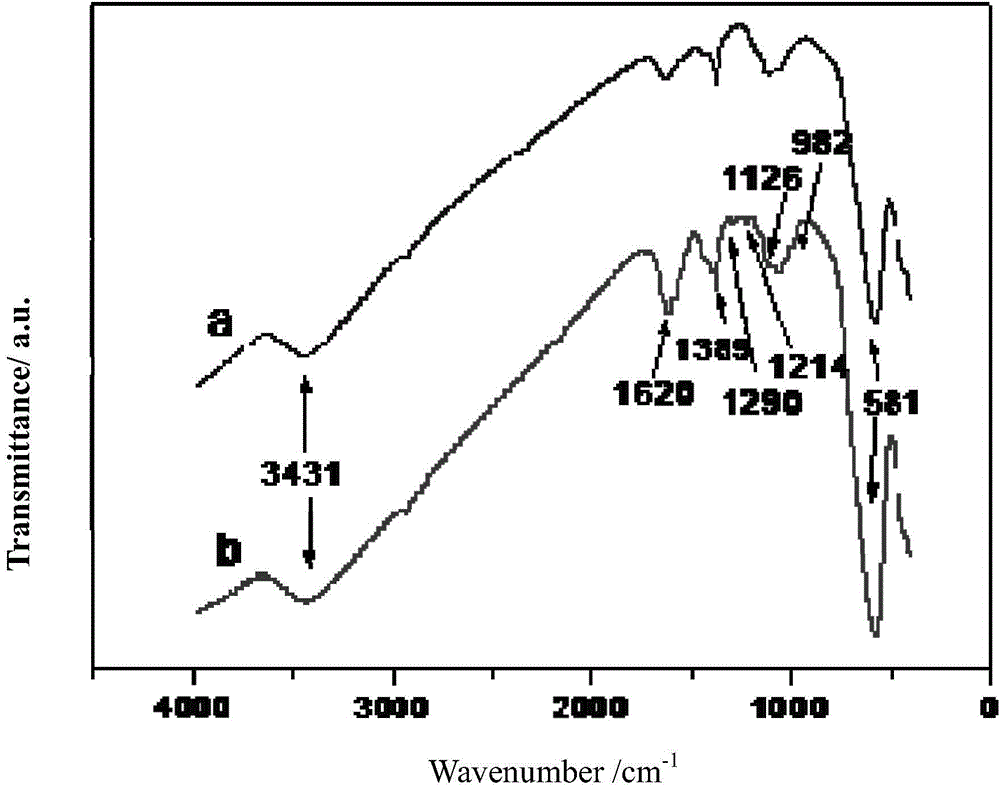

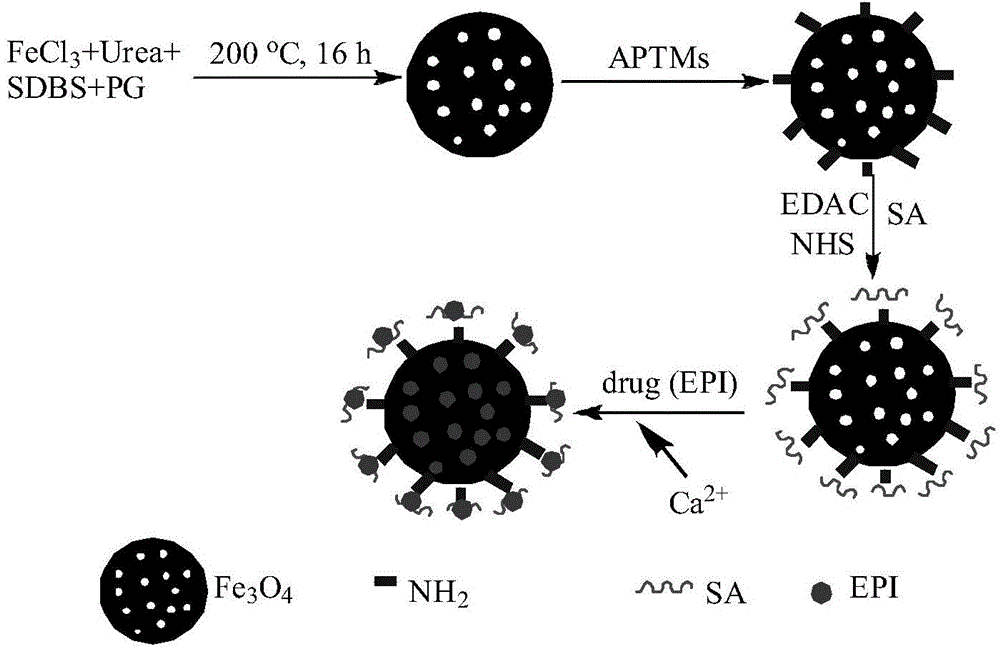

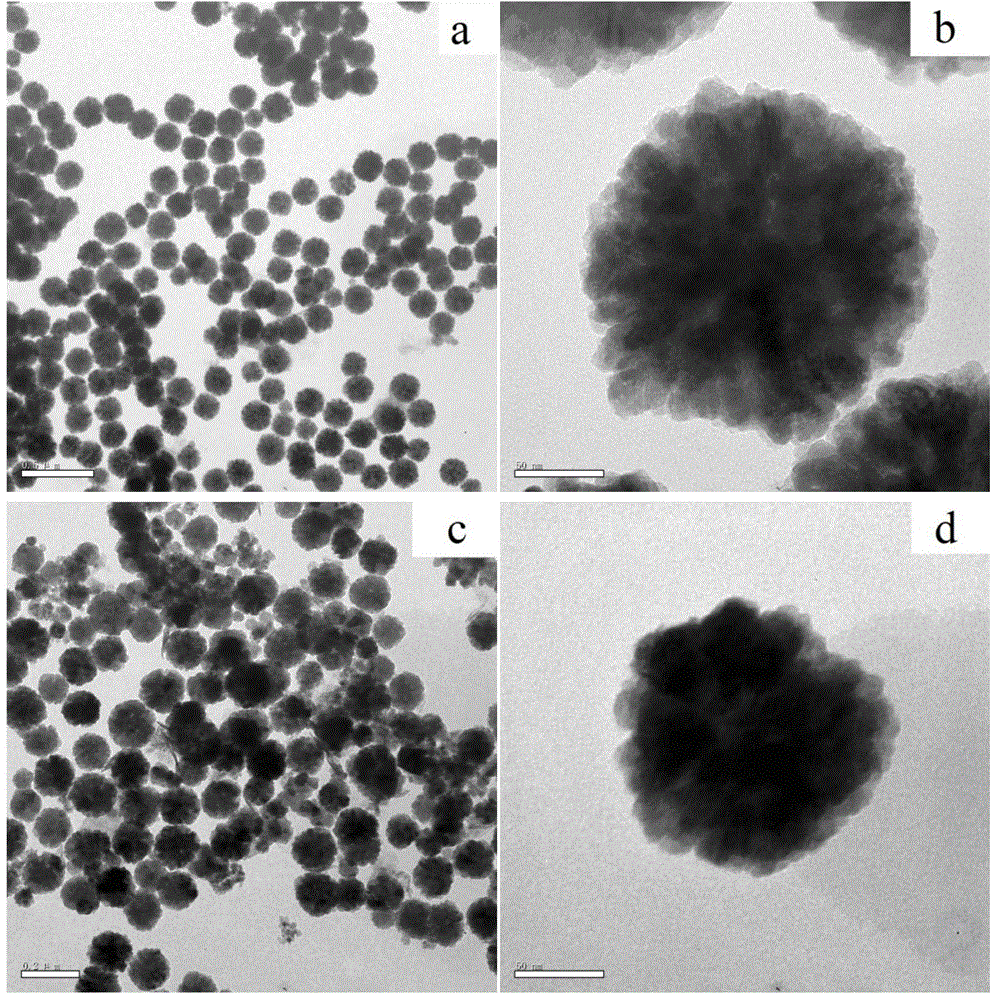

[0036] Dissolve 1.35 g ferric chloride in 72 ml 1,2-propylene glycol, add 0.5 g sodium dodecylbenzenesulfonate and 0.9 g urea to form a mixed solution. After being placed in a reactor and sealed, it was placed in a muffle furnace for 6 h at 220 °C. The product was washed alternately with deionized water and absolute ethanol. Finally, dry at 50 °C to obtain nanoporous Fe 3 o 4 Magnetic microspheres, sealed and kept for later use.

Embodiment 2

[0038] The nanoporous Fe of 60 mg embodiment 1 3 o 4 Magnetic microspheres were dissolved in 90 ml ethanol, 9 ml H 2 O and 3 ml ammonia water mixed solution, placed in a three-necked flask, ultrasonically dispersed for 30 min, then added 1 ml 3-aminopropyltrimethoxysilane, and continued to stir at 25 °C for 8 h. The product was washed with deionized water and absolute ethanol, and dried under vacuum at 50 °C to obtain Fe 3 o 4 -NH 2 Nanoparticles. Dissolve 15 mg EDAC HCl (1-ethyl-(3-dimethylaminopropyl)-carbodiimide hydrochloride) and 18 mg NHS (N-hydroxysuccinimide) in 10 ml PBS (50mM pH=7.4), add 20mg Fe 3 o 4 -NH 2 Nanoparticles were ultrasonically dispersed for 10 min, then 50 ml of 1g / L sodium alginate was added, mechanically stirred for 24 h at room temperature, the product was washed with deionized water, and finally dried at 50 °C to obtain sodium alginate-modified Fe 3 o 4 SA nano-microspheres, sealed and kept for later use.

[0039] The nanoporous Fe of 65...

Embodiment 3

[0041] 5 mg of epirubicin was dissolved in 30 ml of distilled water, placed in a three-necked flask, and the sodium alginate-modified Fe prepared in Example 2 was added dropwise under the action of mechanical stirring. 3 o 4 SA magnetic nanospheres (40 mg, 8 ml water, 0.5% mass fraction), stirred for 6 h, then added 10 g / L CaCl 2 100 ml of the solution was reacted for 30 min and centrifuged to obtain drug-loaded magnetic nanospheres. The product was washed with distilled water, and finally dried at 50 °C to obtain the final product Fe 3 o 4 SAEPI, sealed and kept for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com