Polyamide tree-like heavy metal chelating agent and preparation method thereof

A technology of heavy metal chelating agent and polyamide, which is applied in the protection device against harmful chemicals, etc., can solve the problems of weak resistance to acid and alkali impact, weak long-term stability of heavy metal precipitates, etc., and achieve high long-term stability, excellent resistance The effect of acid-base shock capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

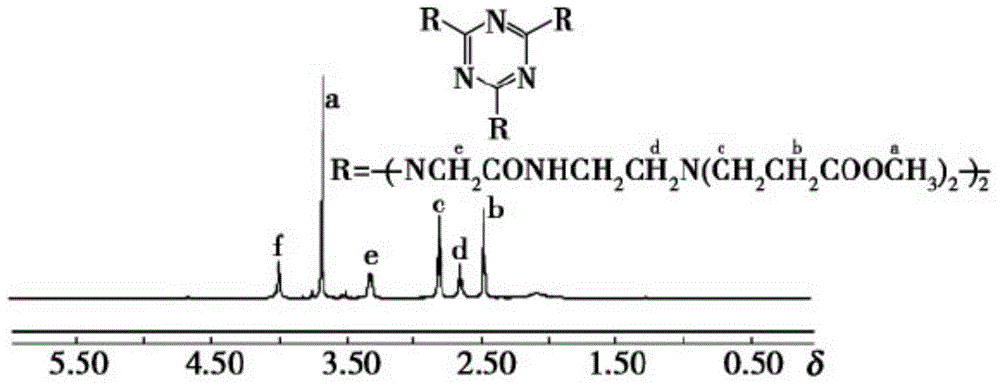

[0083] The preparation method of embodiment 1 polyamide dendritic heavy metal chelating agent of the present invention, comprises the following steps:

[0084] 1) At 0°C, dissolve cyanuric chloride into a mixed solution of potassium carbonate and acetonitrile in the reactor, and then add diethyl iminodiacetate dropwise in the reactor, wherein cyanuric chloride, carbonic acid The molar ratio of potassium to diethyl iminodiacetate is 15-20:1:50-60, and the stirring is continued for 25-40 minutes, the temperature is raised to 20-25°C for 3-4 hours, heated to reflux, and the reaction is 6-7 hours. Take solid by filtration under reduced pressure, obtain carboxylate intermediate I, reaction formula is as follows:

[0085]

[0086] 2) The obtained carboxylate intermediate was washed with distilled water for 2 to 3 times, cooled to room temperature, filtered, dried, and the precipitate was slowly dissolved in methanol.

[0087] 3) Slowly add the methanol solution in step 2) dropwi...

Embodiment 2

[0105] Embodiment 2 The polyamide dendritic heavy metal chelating agent of the present invention is that the preparation method of the dendritic molecular structure with only three linear branches is as follows:

[0106] 1) Preparation of carboxylate intermediate

[0107] Use cyanuric chloride, potassium carbonate and ethyl aminoacetate as raw materials, the molar ratio of which is 15-20:1:50-60, stir for 25-40 minutes, heat up to 20°C-25°C for 3-4 hours, heat to Reflux, react for 6 to 7 hours, filter under reduced pressure to take the solid, wash the solid with distilled water 2 to 3 times, filter and dry to obtain the carboxylate intermediate;

[0108] 2) Preparation of polyamide intermediate

[0109] Dissolve the obtained carboxylate intermediate in methanol, then dropwise add it to the methanol solution of anhydrous ethylenediamine, raise the temperature to 50-55°C for 10-14 hours, and distill under reduced pressure to obtain a solid, which is The polyamide intermediate ...

Embodiment 3

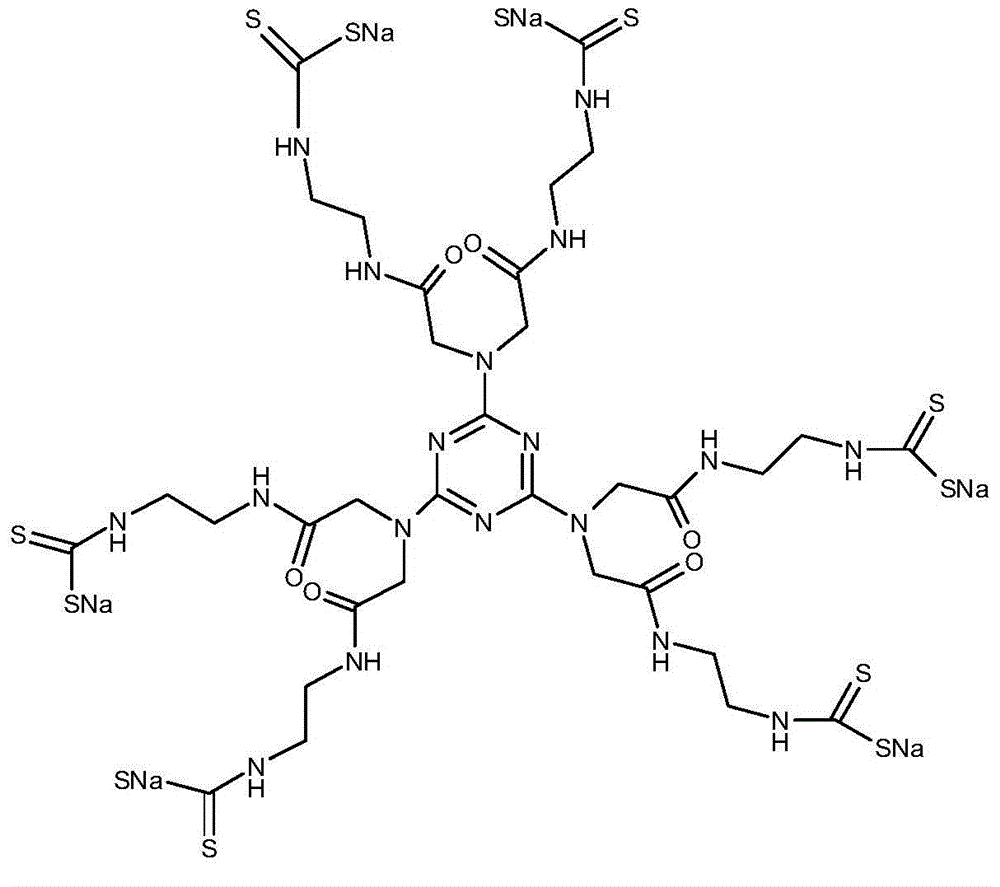

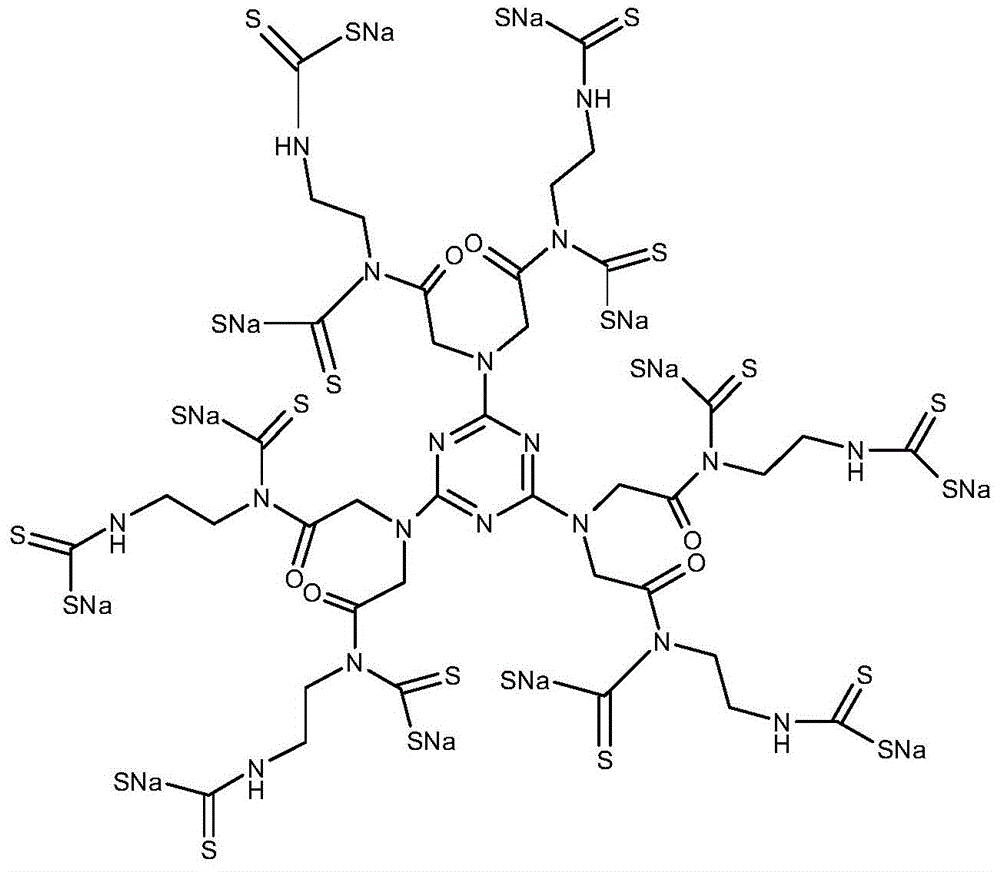

[0124] Example 3 Stabilization treatment of heavy metal dust in a waste incineration power plant along the coast

[0125] Directly add 3g sodium sulfide, 3g thiourea and 3g product 1 of the present invention respectively in the flue gas dedusting ash of certain waste incineration power plant along the coast of 100g (structural formula sees figure 2 ), add 28g of water and stir evenly to make a solidified body of dedusting ash, and stand still for 24h under natural conditions. Then the dedusting ash solidified body was leached according to HJ / T300-2007 (Solid Waste Heavy Metal Leach Toxic Acetic Acid Buffer Solution Method), and the data are shown in Table 1.

[0126] Table 1 Leach toxicity of heavy metal dust after stabilization treatment in a coastal waste incineration power plant

[0127] indicators

[0128] As can be seen from the data in Table 1, the heavy metal leaching concentration in the flue gas dedusting ash after the product treatment of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com