Producing and processing method of toon carbonized wood coating timber

A processing method and technology for carbonizing wood, applied in lignin coatings, wood processing appliances, epoxy resin coatings, etc., can solve problems such as easy decay, reduce the value and service life of wood products, achieve good waterproof effect, improve quality and Economic value, performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

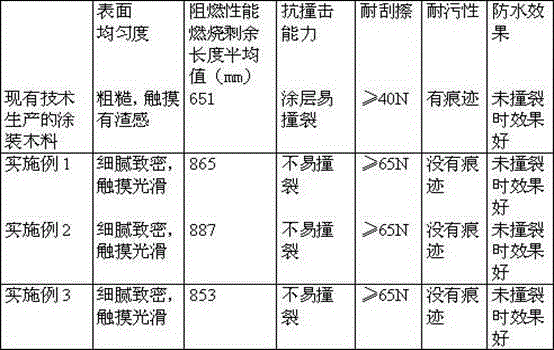

Examples

Embodiment 1

[0023] Roughly process the red toon carbonized wood side material into coarse wood powder below 8 mesh with a pulverizer, and then repeatedly pulverize and winnow with an ultrafine pulverizer to obtain superfine red toon carbonized wood powder with a particle size of 800 mesh; in addition, crush the glutinous rice with Machine rough processing into coarse wood flour below 8 mesh, then repeatedly pulverize and winnow with an ultrafine pulverizer to obtain ultrafine glutinous rice flour with a particle size of 800 mesh.

[0024] Take 18kg of ultra-fine red toon carbonized wood powder, 2kg of glutinous rice flour, and 20kg of clear water, mix them and cook the pulp, then add 1kg of epoxy acrylate, stir for 120 seconds at a speed of 1550rpm, and mix evenly to obtain a repair coating.

[0025] Get granularity and be that 800 order heavy calcium carbonate powder 100kg, solid content are 30% white latex 30kg and glutinous rice flour 8kg mix, stir 120 seconds with the speed of 1550rpm,...

Embodiment 2

[0032] Roughly process the red toon carbonized wood side material into coarse wood powder below 8 mesh with a pulverizer, and then repeatedly pulverize and winnow with an ultrafine pulverizer to obtain superfine red toon carbonized wood powder with a particle size of 900 mesh; in addition, crush the glutinous rice with Machine rough processing into coarse wood flour below 8 meshes, then repeatedly pulverize and winnow with an ultrafine pulverizer to obtain ultrafine glutinous rice flour with a particle size of 900 meshes.

[0033] Get 20kg of ultra-fine red toon carbonized wood powder, 2.5kg of glutinous rice flour, and 25kg of clear water to mix and boil the slurry, then add 1.5kg of epoxy acrylate, stir for 150 seconds at a speed of 1600rpm, and mix evenly to obtain a repair coating.

[0034] Get particle size and be 900 mesh heavy calcium carbonate powder 110kg, solid content be 32.5% white latex 35kg and glutinous rice flour 10kg mix, stir 150 seconds with the speed of 1600...

Embodiment 3

[0041] Roughly process the red toon carbonized wood side material with a pulverizer into coarse wood powder below 8 mesh, and then use an ultrafine pulverizer to repeatedly pulverize and winnow to obtain an ultrafine red toon carbonized wood powder with a particle size of 1000 mesh; Machine rough processing into coarse wood flour below 8 meshes, and then repeatedly pulverize and winnow with an ultrafine pulverizer to obtain ultrafine glutinous rice flour with a particle size of 1000 meshes.

[0042] Get 22kg of ultra-fine red toon carbonized wood powder, 3kg of glutinous rice flour, and 30kg of clear water to mix and boil the slurry, then add 2kg of epoxy acrylate, stir for 180 seconds at a speed of 1650rpm, and mix evenly to obtain a repair coating.

[0043] Take 120kg of heavy calcium carbonate powder with a particle size of 1000 mesh, 40kg of white latex with a solid content of 35% and 12kg of glutinous rice flour for mixing, stir at a speed of 1550-1650rpm for 180 seconds, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com